|

|

|

Site Navigation

Projects & Information

»General Information»Wind turbine Projects »The F&P Smartdrive »Electronic projects »Microcontroller projects »Miscellaneous Kits & Parts

»Basicly Natural Pty Ltd»PVC & Aluminium blades »Scale model farm windmills »Price Watch Discussion Forums

Handy Links

»Wind»Solar »Electric Vehicles »Electronics »Micro Controllers »General Interrest About TheBackShed Getting Started Privacy Policy |

To Decog or not decog. The F&P ( Fisher and Paykel )Smartdrives are basically a dirty big 3 phase stepper motor. When we try to use these motors as alternators for our wind mills or hydro applications, we have to deal with a problem called "Cogging". But what is cogging, and how can we reduce its effects. If we take this motor and spin it by hand ( or by windmill ), it becomes an alternator, generating AC power. The F&P will generate 3 phase AC, up to several hundred watts if enough RPM and torque is applied.

So what is cogging? When we manually rotate the magnet hub, we can feel the interaction of the magnets and stator poles. This attraction of the magnets and stator poles mean it takes more force to start the rotation, than is needed to keep the rotation going. We call this "cogging", basically the reluctance for a windmill to start in low winds due to the magnet/stator pole attraction. One way to explain it. Imagine you have a very old and underpowered 4 cylinder car, and in front of you is a series of hills and valleys. You start from the bottom of the first valley, and try to drive up the first hill, but its a struggle for the tired old engine. Eventually with enough power you make it up the first hill and over the other side, where you speed up down the hill into the valley, then up the other side over the next hill. Once you get over the first hill, your off, you have the momentum to keep going. In fact, once going, the hills and valleys have little effect on how quickly you get to your destination. Same with the F&P, once going the cogging has no effect on output. Its just getting started that's the problem, or "Cog" as we call it. The solutions. Over the years F&P windmill hobbyists have devised several ways to reduce the effect of coggin ( called de-cogging ). No one way is the preferred method, each has its good points and bad points, and it may simply be a case of using the decogging method that suits your skills and available tools. 1. Rounded Poles.

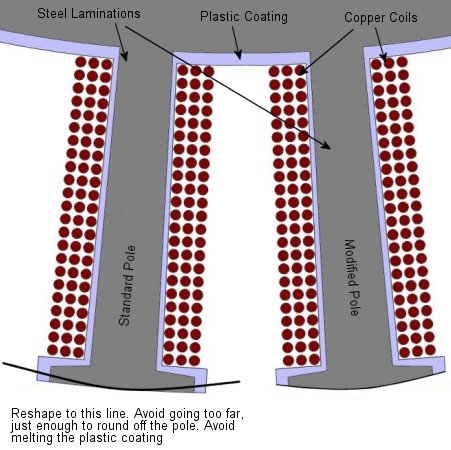

One of the earliest ways found to reduce cogging is to reshape the stator poles. This is done with a hand file, power file, or if your very careful, angle grinder. The danger is you can easily damage the copper coils if your not careful. When rounding off the poles, you only need to take enough material off to slightly curve the face of the pole, if you go too far you can actually increase the cogging effect. When rounding off the poles, watch the heat build up as the plastic will easily melt. Take your time, give the poles a chance to cool.

Recently one of our forum members, CanTinker2 ( John ), has tried grinding the poles at an angle, and has had good results.

Using a 50mm ( 2 inch ) 80 grit sanding drum, he gently ground between the poles at about 10 degrees from origin. This is effectively twisting the poles as well as rounding them. If you have access to some drum sanders then I think this would be the better approach than just rounding the poles as described above, but it does require a steady hand.

2. Twisting the poles. Actually grabbing the face of each pole and twisting it about 10 degrees from origin.

Twisting the stator poles will cause them to lift slightly, and this means an increase in stator diameter, possibly causing it to interfer with the magnet hub. This can easily be fixed with a file or lathe. 3. The 7 Phase conversion.

By combining a magnet hub from a late model F&P Smartdrive, a stator from a early model Smartdrive, and a little re-cofiguring of the windings, we end up with what we call a 7 phase conversion. This miss match of components gives us a alternator will virtually no cogging. The only catch is, while you can pick up the old stators second hand for very little, you do need to buy the newer model magnet hub for about $60 to $80. Power output from the 7 phase is very good, I've seen over 340 watts on my own windmill. Details of the 7 phase conversion are on this page.

4. Bigger turbine. Another way to decog your windmill is to use a turbine with enough torque to overcome the cogging effect in low winds. While high speed 3 blade turbines can make a lot of power in good winds, they are not very productive in low winds or starting from still with a load. So we can either decog our alternator using the methods above, or we can just change our turbine to a low speed high torque design. Its like dropping a V8 into our little car.

5. Further reading.... Forum member Dinges has put together an excelent article about decogging various types of motor/alternator conversions. The article is in PDF formate and definetly worth reading. http://www.otherpower.com/images/scimages/3538/decogging_tutorial_V1.pdf Also worth a visit....

Thanks to Dinges and Clive for posting the links. |

||

The

F&P Smartdrive range of washing machines motors,

and other similar designs like the LG drives, use permanent

magnets hubs ( 5 ) that rotate around a fixed laminated

steel stator ( 3 ) . By switching power to the stator

coils in the correct sequence, we can make the magnet

hub rotate, and there you have a motor. Its a very common

efficient design used in everything from washing machines

to CD roms. Even some of the new hybrid cars use this

type of design as their electric dive motor.

The

F&P Smartdrive range of washing machines motors,

and other similar designs like the LG drives, use permanent

magnets hubs ( 5 ) that rotate around a fixed laminated

steel stator ( 3 ) . By switching power to the stator

coils in the correct sequence, we can make the magnet

hub rotate, and there you have a motor. Its a very common

efficient design used in everything from washing machines

to CD roms. Even some of the new hybrid cars use this

type of design as their electric dive motor.

The problem with twisting is you can only grip the very

end of each pole, any pressure applied to the copper

coils will damage them. Forum member Jarbar ( Anthony

) has fashioned a special tool that neatly fits over

the stator pole, making it easy to twist the pole without

damaging the copper windings. The tool is made from

a scrap length of black bar 20x10x400 long. The stator

poles plastic moldings is 40mm across from the top of

the radius to radius and 14 mm wide. He marked two centers

40mm minus radius 7x2 14mm =26mm apart along centerline

and drill two 14mm holes to about 4mm deep.

The problem with twisting is you can only grip the very

end of each pole, any pressure applied to the copper

coils will damage them. Forum member Jarbar ( Anthony

) has fashioned a special tool that neatly fits over

the stator pole, making it easy to twist the pole without

damaging the copper windings. The tool is made from

a scrap length of black bar 20x10x400 long. The stator

poles plastic moldings is 40mm across from the top of

the radius to radius and 14 mm wide. He marked two centers

40mm minus radius 7x2 14mm =26mm apart along centerline

and drill two 14mm holes to about 4mm deep. Then

mill out the area between the holes leaving the edge

intact. In other words we now have a slot 14mm wide

and 4mm deep and 26mm long to the centres. If you have

a slot drill just mill the slot. This will give maximum

purchase to the plastic molding of pole. You then need

to open the edge on opposite ends to allow maximum rotation

of tool before it impinges on the adjacent poles. After

twisting the poles on first rotation a second twist

would also be possible but probably unnecessary.

Then

mill out the area between the holes leaving the edge

intact. In other words we now have a slot 14mm wide

and 4mm deep and 26mm long to the centres. If you have

a slot drill just mill the slot. This will give maximum

purchase to the plastic molding of pole. You then need

to open the edge on opposite ends to allow maximum rotation

of tool before it impinges on the adjacent poles. After

twisting the poles on first rotation a second twist

would also be possible but probably unnecessary.

A

turbine with more blades or bigger diameter will give

more low speed torque, at the cost of high speed/RPM.

By using say a 5 or 6 blade turbine we gain the torque

to overcome cogging, but we will loose some high speed

performance. It really depends on your location. If

you live in a low wind area, then using a turbine with

lots of torque will work best for you. You windmill

may only make 200 watts max, where a high speed turbine

could make over 300 watts. However, your windmill will

be making more power more often. A slow running windmill

that makes 100 watts for 5 hours has made more power

per day than a fast running windmill that made 300 watts

for 1 hour.

A

turbine with more blades or bigger diameter will give

more low speed torque, at the cost of high speed/RPM.

By using say a 5 or 6 blade turbine we gain the torque

to overcome cogging, but we will loose some high speed

performance. It really depends on your location. If

you live in a low wind area, then using a turbine with

lots of torque will work best for you. You windmill

may only make 200 watts max, where a high speed turbine

could make over 300 watts. However, your windmill will

be making more power more often. A slow running windmill

that makes 100 watts for 5 hours has made more power

per day than a fast running windmill that made 300 watts

for 1 hour.  My

best performing windmill is a 6 blade, 2.4 meter diameter

turbine on a dual stator windmill. The stators are no

decogged, they didn't need to be. The windmill peaks

out at 15 amps, not much, but its up and running in

the lightest of breezes and supplying a couple of amps

all day long.

My

best performing windmill is a 6 blade, 2.4 meter diameter

turbine on a dual stator windmill. The stators are no

decogged, they didn't need to be. The windmill peaks

out at 15 amps, not much, but its up and running in

the lightest of breezes and supplying a couple of amps

all day long.