|

|

Forum Index : Windmills : 7 phase F&P using hard drive magnets

| Author | Message | ||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

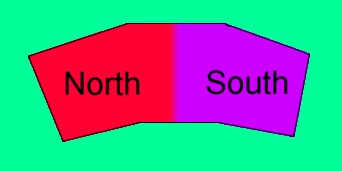

Retraction: Further to my earlier testing of magnets I have used a compass to identify exact pole locations on a test magnet then used it to test all my HDD magnets. Contrary to my earlier findings using a piece of broken HDD magnet, the test showed one North & one South Pole on the face, one either half.

This means my earlier conclusion that there must be two types of HDD magnet is unfounded. Spiral's magnet arrangement is likely to suit ALL HDD magnets (physical size permitting). was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hey Gill, No Probs, they still make excellent fridge magnets. The walls of my shed are covered with them, holding up an assortment of bags and tools etc. I have only found a very early seagate drive that had a curved magnet arrangement, where the voice coil was in and around the permanent magnets. A bit like a speaker arrangement, but curved. I have not been able to debond the magnets either. I still have my doubts with stronger magnets. I do see a benefit for a VAWT though. .. .. Gordon. become more energy aware |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Hi Spiral, I had quoted from my leaking memory when I said 200W@200RPM. Looking at my test sheet, which I just fetched from the workshop, the results were: 220RPM, 15.3V/6.5A into 2.3Ohm load (~100W) 300RPM, 14.6V/16A into 1.1 Ohm load (~233W) I also tested at 410RPM and got 17V/18.7A (~317W) and 550RPM, 16V/ 21.7A (~347W) - things got rather hot with the last two tests. As you see I used a rather large (multitapped) resistor, with a fan cooling it, as a load as I did not have big enough batteries available then. Note that the last two tests used paralleled resistor sections to get a small enough R value but I don't have a low Ohm meter to measure exactly what value it was. Using resistors is a start for experimenting but practical figures are best obtained with a battery load. When I get around to set the test up again I will use a big 12V (or 24V) battery and load that up with my multitapped resistor, then measure the charge that the 7 phase F&P can supply to that. From the above results (standard F&P magnets on new style hub) you can see that you need much more powerful rare earth magnets and a small airgap to beat that. Tinker Klaus |

||||

| spiral Newbie Joined: 06/05/2008 Location: Posts: 12 |

Thanks Klaus, I appreciate the references. This will give me a mark. By the way I read one of your posts, nice looking F&P, very clean work. Next time I go to the cabin I will bring home my charge controller and a slightly discharged battery, and retest. I also should check the resistance of the bulb arrangement I used. If anyone is so inclined I would love to know the measurements of the new hub magnet layout. The width of each pole, block, etc. I just divided the hub into 48 even sections assuming that is the way it is layed out. Actually I should probably ask if anyone has a new style hub they would let go of, it would help with testing and be a good backup, since it sounds like output may not be any better than the original. I am located in the U.S., so if there are any from the states, that would be great. At this point I am going to take out the magnets and just lay them out for 1 phase, this way I can change the magnet placement a bit and check for differences faster and hopefully more accurately. After that I want to work on the air gap issue. I can easily remove some of the laminations and add another magnet, or I can add another lamination to get the magnets closer to the stator. Adding another magnet sounds more interesting so I will start with that. Although I fear cogging will become an issue. Then I want to try to shorten the length of the magnet by sanding each end down a bit to get them to fit lengthwise into the right N/S configuration. There are many things to try. |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi spiral, I am not sure what a 1phase arrangement is for the magnets. I can see how only looking at one phase with all the magnets might work. I would not reduce the thickness of the iron backing in the rotor. This is used to complete the magnetic field. Stronger magnets should require an increased thickness. Take care with dust from any grinding or sanding of the rare earth magnets. Boron can't be good inhaled, or absorbed through the skin etc. .. .. Gordon. become more energy aware |

||||

| martinjsto Senior Member Joined: 09/10/2007 Location: AustraliaPosts: 149 |

hi spiral, welcome to the site, i have also tryed the hard drive magnets with ny first neo conversion, but still havnt finnished it yet, work keeps getting in the way

as for testing the output have a look at this post 12v rewire vís 48v rewire for charging there is some great info on the proceedure for testing on a lathe. good luck martin free power for all McAlinden WA |

||||

| spiral Newbie Joined: 06/05/2008 Location: Posts: 12 |

Hello again I have done a little testing and come up with what might be a better output. The pictures I posted show the magnets in the pattern that gave me my original test data. I got up to 120watts at 300RPM with that arrangement. I then took all the magnets off except 1 pair of N and S. In that original layout these tested at 5.3V and .06A, .318W when spun at 300 RPM. After a lot of different arrangements, I found that when the magnets were cut in half I started getting better output. So far the best I've gotten from filling just two 'sections' is 10.5V, .17A, 1.78W. This was done with 4 N magnets with some sheet metal between the mags, followed with 4 S magnets with the same metal between them.(The sheet metal helped with the air gap and kept the magnets from wanting to stick to the stator laminations) These are layed out 2 magnets high with 2 piles per 'column'. I divided the hub into 16 sections with three columns per section. That makes 48 sections total. I tried a few other variations on spacing but the 48 section layout seems to work the best. So far I have only filled two sections, so who knows what will happen when I fill more. It is interesting to see what arrangements cause cogging and which ones don't. There is a bit of a trade off between output and how much cogging there is. When all is said and done I would rather have less output and no or minimal cogging. This is still just one of many ways to lay this out, but it seems to put out more output and it doesn't seem cog very much. I am going to add some more magnets in this arrangement when I get back to this. Wish me luck. If I come up with something that I am happy with I will post pics. Thanks for the safety and the testing tips. I found nitrile gloves stand up to the pinching of the magnets very well, and keep my skin off the magnets. I Probably wouldn't have used them had you not mentioned it. |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Hi Spiral, Maybe somebody will correct me if I'm wrong but I seem to recall from my trade school days that one cannot have a SINGLE pole magnet. There is ALWAYS a N and S pole. If, as I imagine you did, you cut a HD magnet in half, the original of which had a N and S pole on the SAME surface, you get a similar polarised magnet, only half size and less power. I think you have to remagnetise your cut HD magnets so their poles are as below. What you need is a magnet that is magnetised THROUGH the body, eg. having the N pole on one side and the S pole on the reverse side. This will let you place a N pole magnet tile alternating with reversed (S pole up) magnet tiles on your rotor laminations. Tinker Klaus |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Klaus, You are not familiar with the magnets that have been discussed. The magnets are really 4 poles. The poles are according to the pictures posted elsewhere on this thread, and the poles are through, between the opposite faces. Spiral has described the N & S inner pole faces. There is obviously the corresponding opposite pole face for each of the N's and S's that he described. .. .. Gordon. become more energy aware |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Thanks Gordon, for enlightening me. It did sound confusing in the message I referred to. Tinker Klaus |

||||

| spiral Newbie Joined: 06/05/2008 Location: Posts: 12 |

If there is any confusion I would be happy to explain, just ask. I have not had any time to work on this and may not for a few days due to work but I am looking forward to getting back to this. I am having a lot of fun. If there is anyone who has some spare F&P parts, and some of these magnets laying around. I think they should take out the original mags from a spare hub and play. You can get readings from just a few magnets. It was interesting to me to try different arrangements and see the effects. My best readings were in an arrangement that is similar to the original newer style F&P hub pattern( I found the picture of the hub magnet on this site. It has slightly curved, and less magnets.) One thing I did have to do was epoxy the top edge of the laminations. They wanted to separate and pull toward the stator which resulted in rubbing and magnet shifting. I just used painters tape to make a little channel for the epoxy and it eliminated that problem. I have a feeling I will boost output quite a bit with the arrangement I described in the last post, as it has twice the magnets and takes up half the space as my first(In the pics I posted) layout. It also seems to work and cogging felt fine. When I have a little time I will get back to work. |

||||

Steve9R Regular Member Joined: 24/01/2006 Location: AustraliaPosts: 72 |

Just found this old thread on HDD magnets too.. thought it might be of interest.. http://www.fieldlines.com/story/2006/2/9/13128/15117 Steve |

||||

| Hybrid Newbie Joined: 05/05/2008 Location: AustraliaPosts: 19 |

spiral it's good seeing someone playing with magnets. I'm designing a magnetic repulsion motor with staggered magnets to make the repelling smoothe. The armature will have 2 bearings. The outer barrel will be moved L/R to align the rows of magnets. Full overlap is top rpm etc. One row of the same pole will be for braking. I will be getting custom octagonal bar magnets made up to lessen the field before & after. When I find the right amount of magnets needed to repel at high rpm with a load, I will post it in here. My aim is to put out enough amps to run my 8" DC electric motor at 110+kph without batteries. I don't think the magnetic motor would push 1,300kg at a decent accelleration. But the DC motor will. Cheers ! --Anthony Petrol FWD & Electric RWD |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Anthony, What is the source of power? Do you intend to still run as a hybrid? Gordon. become more energy aware |

||||

| Hybrid Newbie Joined: 05/05/2008 Location: AustraliaPosts: 19 |

Hi GWatPE. No power suplied. No coils. 1mm air gap between inner N + outer N poles. Alignment of magnet rows followed by offset rows. Lowering the field before & after is something I have sorted out. Direction of repel from neutral I can overcome as well by what I use either side. I plan to use 112 magnets in my test setup. Money is an issue atm tho. Pension doesn't pay much

Cheers ! edit - Sorry GWatPE I forgot to answer your last question If I can't achieve enough power to run the rwd dc without batteries at a minimum 250a, I'll have to see what my gmw will add up to with petrol ice, 2 elec motors & batts. Somehow I don't think my Mitsu will be under weight ;[ I bloody hope all goes well. I realy want fwd + rwd. Cheers ! --Anthony Petrol FWD & Electric RWD |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |