|

|

Forum Index : Windmills : Furling

| Author | Message | ||||

| moe46 Newbie Joined: 21/06/2008 Location: Posts: 4 |

Great site, great people! Dense beginner struggling on the furling page. Q1: What causes the tail to rise up? Yes it is hinged in that plane, but I see no upward wind force to raise it and minimal tail surface area in that plane for wind to work on. Is it something to do with the 20 degree angle and the fridge door analogy? In which plane is that 20 degrees? Q2: Why is the first stop and the vertical movement needed in the first place? Wouldn’t the assembly find equilibrium at any speed without them anyway? Thank you |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

If I understand correctly... The tail is on an inclined pivot which in its at rest state puts the tail fin parallel to the axis of the turbine. Pushing the tail to one side causes it to raise and when released it returns to the inline position. The 20 degree angle is 20 degrees 'tilt back' from verticle, i.e. viewed from the side of the mill it is tilting back, viewed from the front of the mill it appears verticle. The axis of the turbine is offset from the axis of the yaw pivot. In light wind conditions the weight of the tail causes it to stay in the at rest position and in this state keeps the turbine blades at right angles to the wind. When the wind force on the blades increases the offset of the turbine axis from the yaw axis tends to move the turbine off the wind and this force is balanced by the weight of the tail seeking to stay in the at rest position. Further increase in wind caused the force of the turbine offset to overcome the effect of the tail which rises. I dont know about the stop, maybe to stop the mill from continually seeking on and off the wind? How did I go? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day moe46, welcome to the site. It seems the geometry of furling is a difficult one for some to understand. This is made impossible if you don't have the exact physical placement of the parts, then the physics won't work. Firstly John has given you a bum steer saying the 20 deg is in the plane of the end elevation and not the front elevation. This is incorrect. It is neither the front or side elevation. It is on the plane drawn at 45deg to the prop shaft's axis. Knowing this you may conclude that the tail will seek that angle for it's lowest point of travel about the pivot if no stops were fitted. This is not where the tail needs to be positioned, hence we use stops and, like a fridge door, we get a closing force against the stop. Only when the closing force is countered by the opposite force of the high winds against the offset prop will the door open. It is not the tail that moves but the prop about the yaw bearing. The top stop then saves it from smashing into the prop as things swing about in high winds. Hope that's helped. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Thanks Gill, now I still dont understand the angle of the dangle, or whatever!

[later] Thinks, hmmmm so that 45 degrees is so that as the mill yaws the tail fin is not twisted about the axis of the tail boom? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Tail fin twisting about the boom?????? There is no pivot between the fin and the boom. I think you're getting further away now. The thinking of the pivot angle as coming straight out the back is closer but as moe46 understands it would be in equilibrium. the stop would serve no purpose and in fact there would be no resistance to furling until the prop had furled a huge number of degrees. Like our fridge door example that uses a circular inclined plane to close(helix), it is in equilibrium only by the fact of the door against against the wall (a stop) which gives resistance to it's seeking lower points on the helix. The helix has not caused equilibrium but the door frame has. So to our stop resists the boom from seeking it's lowest point (at 45deg), rather it is held say straight out the back (no advanced theory comments please) and has a pre-load that is equal to the turning moment of the prop at FURLING SPEED. Then it is truly in equilibrium of wind and gravity forces. The stop and the per-load keeps the windmill working into the wind for normal operation up to furling wind speed. A further increase in wind adds further prop turning moment about the yaw bearing and there is wind resistance on the tail, because the tail cannot move with the yaw bearing, the tail keeps pointing into the wind leaving the prop at an angle(partly furled). And so it goes until fully furled. I hope that helps.

I keep looking for different ways to say all this using the terms already mentioned where possible. No good repeating over again what I have said in other replies. I still can't find the one size that fits all though. People being people, I guess I never will. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| sodes Newbie Joined: 26/07/2006 Location: AustraliaPosts: 21 |

Don't worry KiwiJohn I was a little confused about it all at first and questioned the angle of the dangle but what I guess Gill is saying is that where the base of the pivot pole is mounted is 45 degrees relative to the propshaft but the angle of the pivot pole itself may appear as 10-15 degrees outwards and 10-15 degrees rearward. I guess if it didnt have some angle outwards there would be no pressure against the no-wind stop and the tail would flop around a fair bit. Also by angling it both outwards and rearwards will force the tail upwards on a higher plane probly high enough to clear your genny stator and so on. Anyway thats what I make of it!  I'm hoping to start work on another gen soon and try it all out. Cheers Sodes I'm hoping to start work on another gen soon and try it all out. Cheers Sodes"Do, or do not... There is no try." -Yoda |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Moe46, I once made an animation of the furling system. It can be found here: (warning - 8 MB .avi file) http://www.anotherpower.com/albums/dinges/animation_yaw_asse mbly.avi The pushing force of the offset windturbine (that wants to be pushed 'out of the wind' because of the offset) is compensated by the tail that wants to remain in the wind but, to do so, has to rise against gravity. Thus, the tail weight and offset of the turbine results in two forces that balance eachother. edited: for some reason I can't get the URL to display properly. Remove the space in 'asse[space]mbly'. Or visit this link: http://www.anotherpower.com/gallery/dinges?page=5 |

||||

| moe46 Newbie Joined: 21/06/2008 Location: Posts: 4 |

I am starting to understand. Dinges's animation helped a lot. Gill; please correct me if I am wrong. Here goes. When furling speed is reached and the tail starts turning around the mast axis because of the turbine/tail offset momentum – the tail will actually twist off vertical because its pivot is angled by 20 degrees. This creates a lift component on the tail which – if/when it becomes greater than the tail weight - will raise the tail over the stop and furling starts. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

OK, let me correct a little; "turbine/tail offset"_ turbine offset - yes, tail offset - no and irrelevant. The thing of most concern is use of words like "lift", "raise the tail", and "greater than the tail weight". I get the impression you see a vertical movement as a part of the furling process. It is not. I could just as easily design the same furling system to use a vertical pivot and spring. The forces we need are lateral,, none vertical. The 20deg off vertical uses gravity to give the tail side thrust. Lateral side thrust is what we need. The result of this is that the tail swings up as it furls. It would be better if it didn't. We don't need lifting forces just side forces. Any lifting action of the tail is a consequence of using gravity to generate a side thrust resistance and is nothing more than a nuisance by-product. When you have a working system to play with it does become more understandable. But I guess that doesn't help if you don't have access to one. Still, you're well on the road to full understanding.

was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Gill, re 'twisting about the tail boom", doubtless a very poor choice of words on my part. This is what I was thinking of, with the fin in the non furled condition the plane of the face of the fin is verticle. When the mill is fully furled the tail boom is at 90 degrees to the axis of the mill and the tail boom is canted up (45 degrees ?), and the face of the fin is now not verticle(?). One day when I no longer live on a little square of dirt in the city I will actually build another mill and my knowledge will then extend beyond what I glean by reading this forum!

So far the only mill I have built had very basic furling in that the turbine was offset and the fin only big enough to hold it into a mild wind. It worked quite well but in strong wind conditions it was continually swinging on and off the wind. Hmmmmm, maybe I should build a little one on the pattern favoured on TheBackShed!  |

||||

| moe46 Newbie Joined: 21/06/2008 Location: Posts: 4 |

Ok Gill, I get the message  . I will just have to stop shuffling my feet and build one. Wish me luck and thanks to all. . I will just have to stop shuffling my feet and build one. Wish me luck and thanks to all. |

||||

| moe46 Newbie Joined: 21/06/2008 Location: Posts: 4 |

One final flash before I go away and start working  . .

I think what confused me is where it says "the weight of the tail will want to turn the tail down" then further on "the tail is lifted" which I took literally and got sidetracked into this up down motion. Actually it really means that the stop is rotating counter clockwise with the turbine while the tail stays downwind thus they part company while still in the same plane. If I understand correctly now, virtually all furling movement is in a horizontal plane. The 20 degrees is just to keep the tail against the stop by gravity until furling speed is reached and make it gravitate back towards that position when speed drops again. If so, then is the 72 km/hr used in the calculations reasonable for a lowly first effort or should I be more cautious? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

moe46, Yes,yes,yes, That's it. Now you've got it.

No the 72km/hr is already cautious I feel. I made my mill to furl at 80 km/hr and wonder if I've made it is still too low. When I first made it it furled at about 20 to 25 km/hr so had to greatly reduce the prop offset as the amount of extra weight required on the tail was huge. The calc we use produces a very heavy tail which is not correct. The problem is in over calculating the wind thrust onto a prop. Another area not addressed in the basic theory page is that the tail does not sit directly into the wind. The prop moments(of force) and the tail moments need to balance hence the tail will sit sit at up to 20 deg into the wind to get a balancing force against it. This puts the prop 20deg off square with the wind. This can be spotted by the keen eye though it doesn't reduce the power by much. Still the astute builder will build the stop to allow 15 to 20 degrees extra or kink the boom by that much just before the tail. 20deg out to the wind is not so visible but a tail 20deg out of square is. Question is, do you want to design for looks or performance? Best wishes for your future windmill projects. we'll all appreciate little stories with one or two pics showing success or failure. It inspires others with new ideas.  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

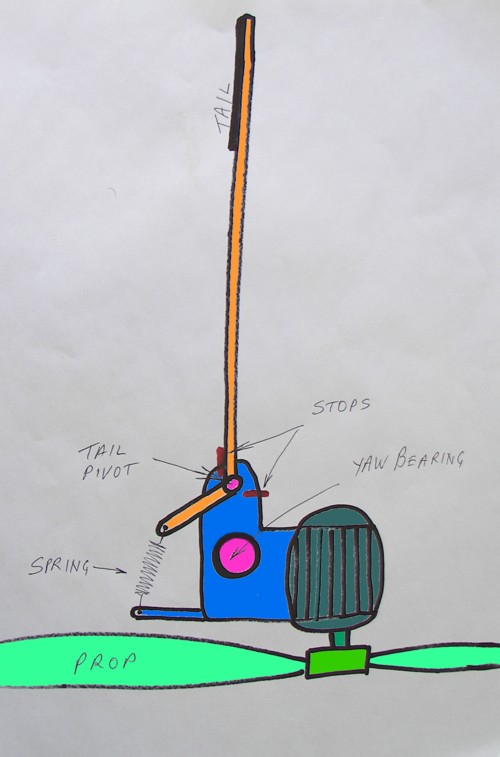

John, Both the lifting and the twisting is a by-product of the 20deg we need for a gravitational induced side thrust. It would be less confusing if it didn't do those things. Here is a spring mechanism as opposed to our gravity mechanism. It uses a vertical pivot and no tail offset which are the source of most confusion. For basic understanding I did not allow the 20 degree extra in the low speed stop.

For a spring mechanism, 2 variables need be considered when designing; the resistance of the spring, and the preload. The resistance dictates the force needed to take it from one stop to the next(wind speed at start of furling to wind speed at fully furled). The preload gives the zero or the force at which furling starts(sets furling wind speed). I'm sure this is easier to understand furling basics with. Gill EDIT: I can expand further on setting up an adjustable spring mechanism if needed. For those considering spring furling this law will be of intrest: "The extension of a spring is directly proportional to the load applied". was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |