|

|

Forum Index : Windmills : blown up and still 800 watts AWP

| Author | Message | ||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Well it's always still when you raise em, and blowin a gale when you gotta pull em down. Jamie's African Wind Power decided to blow a phase today. It was still putting out over 800 watts as we started to winch it down. (Kill switch wouldn't slow it enough to snuff it out) It was doing 16A@56v which was low for this machine, should have been 25 or so. A quick check of the bridges, freq control panel (turns on the transformers when enough revs via solid state relays). Checked the three phase transformer. It confirmed what we were hoping was not the case... the mill had a phase missing. This is a 240v generator, and we had 300 odd on two phases and 4 volts on the third. Now this means leaving the genny shed and making our way to the top of his hill. The wind was blowing strong and chill, and some rain turned up just to add insult to injury. We checked the lightning arrestor box, the twist plug and any thing else that would delay having to pull her down.... alas, it looked to be up the tower. So down she came, and our worst fears were confirmed.... a burnt coil in the stator.

Here is a picture of the front of the genny (after some mods a year ago

Here is the bearing carrier:

It has ceramic magnets, which are weak as water but still put out lots of power. There are thirty of them:

The stator has 90 coils three phase star. It is of cogless design with the laminates slanted to give the cog free stator:

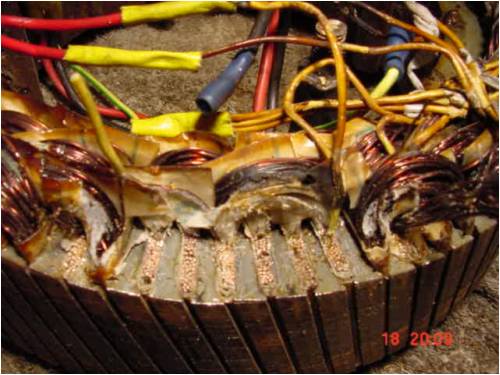

So I hacked the coils up with a chisel like so:

and then cleaned it up a bit:

and thats it for tonight. Soon she should be back up the pole putting out her 24kwh/day again ..............oztules Village idiot...or... just another hack out of his depth |

||||

CraziestOzzy Senior Member Joined: 11/07/2008 Location: AustraliaPosts: 152 |

Damned big bummer ... did you manage to find out the cause of the short? ...nice lams btw  http://cr4.globalspec.com/member?u=25757 http://www.instructables.com/member/OzzyRoo/ |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Just another day in Oztulesville :) Sorry to hear about this. I remembered you working on this very machine about a year ago; BTW, I looked up these two links where you described the first part of repairing the AWP; may be interesting to new readers too to see what happened before: http://www.otherpower.com/images/scimages/5171/awp_1.html http://www.otherpower.com/images/scimages/5171/awp2a.html They're excellent descriptions, they deserve to be read by newer members (or older members with lousy memory as yours truly). I had to look up whether you initially rewound it but apparently not. It's safe to blame the manufacturer in that case. Then again, like motors, generators can burn out over time. It just happens. Will you completely rewind the stator, or just the part/phase that is burned out (if that's even possible) ? Sorry to hear about your (friend's) misfortune. On the bright side, he's lucky to have you around. I have complete trust in your ability to get it running again soon. After all, it's just another rewind job. If you can source the materials the actual repair should be an easy job. A lot of work, but not difficult. |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

Sorry to hear about the AWP unit.  I remember reading your previous posts and have to wonder about their dependability. I remember reading your previous posts and have to wonder about their dependability.

From looking at the photos, it seems to be well made. You must have strong winds. Great photos and post. Very enjoyable. philb |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Crazy, It appears to be just poor manufacturing again. When they wound the stator, they dipped it to weatherproof it. Some parts are knee deep in lacquer, and some a bit sparse. So in this marine environment, it looks like corrosion has gotten into some of the coils, which after a while start conducting between "green corroded bits" at these high voltages (unloaded over 500v). This then makes a happy little arcing machine that busies itself burning still more enamel off and away we go. charcoal maker. It is not from overload. This machine can stand shorts on the outputs all day long. Great design, pitiful quality control. Dinges, This is what I get from casting aspersions on your calculations. I knew you'd get me somehow. "Its safe to blame the manufacturer in that case".... yep. I guess this shows that if you want to go for a HV generator head, then good insulating practices are paramount. This time around, will just rewind the bad bits.... and some bits I had to pull out from being over enthusiastic with the chisel  . .

Just to annoy you, I will use the field windings from a car alternator I spied on the floor of the shed. It appears to be close in wire size and a doddle to unwind. This will get it going quickly. New wire will take .... who knows how long to arrive. He doesn't want to burn diesel every day at 2 dollars a liter. We can then get Jamie to order the proper wire (new) and rewind the whole thing properly. (although me and properly should not be used in the same sentence). The winding is a six stage one consisting of 15 coil groups x 6.... ie the inner "ring" has 15 coils as half a phase then the next is 15 coils of half of the next phase then 15 coils of half of the next phase blah blah blah. Thats a bit complicated.... lets see ring 1 phase A 15 coils evenly spaced around 90 slots ring 2 phase B 15 coils evenly spaced around 90 slots ring 3 phase C 15 coils evenly spaced around 90 slots ring 4 phase C 15 coils evenly spaced around 90 slots ring 5 phase B 15 coils evenly spaced around 90 slots ring 6 phase A 15 coils evenly spaced around 90 slots (yes I learned to cut and paste). Thats 90 coils to wind of 55 turns each .8mm wire. Coil width is three slots. So coil, miss three, coil, miss three, etc until 90 slots done then the next layer. It was a dog to get the wire out off, as the slots are very deep and skinny. Yes, He did mention that he would have had a difficult time getting anything out of it if I weren't here to solve it's shortcomings. It is still an excellent performer, well designed, terribly built machine from Zimbabwe. However I think they have more to ponder than looking after customers.... like making it to the weekend with their head still attatched. This is a real shame. Otherwise they would have a world beater of a mill on their hands. There can't be too many 3.6m machines making the kind of daily power that this one does. After all the talk I see on fieldlines about how impossibly hard it is to just heat water, this one runs a full size hot water unit as well as the rest of the house no problems. It puts out more power each day than I use at my place on the grid. (elec hot water, stove oven 5' telly, water pumps etc etc.) So it must see some serious winds. I use 16kwh/day, this thing rarely does less than this , more usually 24kwh. ........oztules Village idiot...or... just another hack out of his depth |

||||

CraziestOzzy Senior Member Joined: 11/07/2008 Location: AustraliaPosts: 152 |

Cheers for that reply Oz....and those two links are truly impressive...had to wipe the drool off my face several times  http://cr4.globalspec.com/member?u=25757 http://www.instructables.com/member/OzzyRoo/ |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |