|

|

Forum Index : Windmills : Ideas on how to speed up a motor?

| Author | Message | ||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

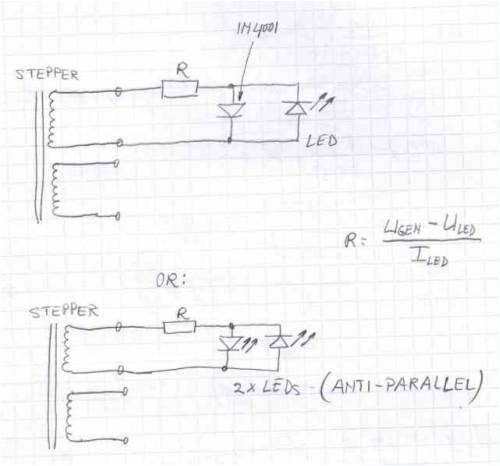

My thought, Oztules. Those blades most likely aren't the limiting factor here. 0.8 m diameter should provide plenty of power to the shaft. And I very much doubt that the tiny stepper could pull a properly made PVC blade into stall... Then again, I'm no blade expert. It would be nice if Mahela could supply a good picture of his blades. Maybe there's something wrong with them (or not) that's immediately obvious to someone here. Mahela, are you are sure the blades of the turbine turn faster than what you handcranked (120-180RPM) ? Another thing you could do is take a cordless drill and use it to turn the shaft. Many cordless drills have 2 selectable speeds and, in case of my drill, it's very close to nameplate speed (verified with RPM counter, 300 & 600 RPM). That way you'd have some indication of how the generator itself performs at 300/600/whatever RPM. You'd be able to give a more accurate indication of RPM than by just guesstimation. If the drill can easily power the stepper and LED and the blades can't, there may be a problem with the blades, either with attaining the required RPM or power (unlikely, if the blades are .8m dia and if just *slightly* efficient). As said before, it'd be in your own interest to supply a few pictures here of the system (blades, wiring, rectifier/diode). Someone may be able to tell at a glance what's wrong, or what isn't. At the moment it's still guessing exactly what you have there; how your blades look, the wiring diagram, the voltage the generator puts out, etc. In the mean time, here's a quickly scribbled schematic (essentially the same as what Gordon told). You could try wiring up the LED (or the 2-LED variant, if you prefer) and see if your blade can get that to light.

The resistor could probably be a small value in this case, 47 ohm to 220 ohm ? You can calculate the exact needed value with the equation that's in there but you need to be able to measure voltage of the generator for that. Maybe I'm not understanding correctly, but are you saying that you didn't actually measure output voltage (after the rectifier), but calculated it (in other words, assumed you had power/voltage there) by adding rectifier voltage drop to an earlier measured generator voltage ? A simple multimeter is an absolute requirement for these kind of experiments. The cheapest DMMs over here are 3E (5 US$). You'll be using it long after this project is finished (as long as you take good care of it, as in "don't measure the resistance of the powergrid!" as my brother once did... Trying to measure voltage with the DMM set to the ohm-range. Never seen so much sooted components in one appliance before or since. Was an expensive DMM of my father too in a time when DMMs were still 150$ items) ) |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

ok.. I will post back with photos of my blades how come its not very windy where i live??? |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

First off, here is a link to pictures of the blades http://www.flickr.com/photos/9937638@N02/ As for the RPM: I have no way of knowing exactly the RPM when i handcrank my motor when it is not attached to the shaft. But I did however manage to calculate the RPM Of the windmill when it is spining (and connected to the motor) It is 252 RPM + or - 25. I had no time yet to test the shematic you provided. I will make sure to test it as soon as I verify that the blades are ok (or are NOT OK ....lol) pls let me know if the quality of the photos is not enough for you to determine any details. I'll try to post better ones how come its not very windy where i live??? |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

Does anyone know if the blade calculator on this web site works for PVC blades? EDIT: I just checked it our.. and it seems way too complicated for me. I just want "thingies" which will make my windmill turn when wind hits it. Some simple proportion will help me much more.. (thanks for the help though OZTULES) for example I found somewhere that the tip width should be about 20% of the width of the base. but it does not mention the length of the blade how come its not very windy where i live??? |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Ok... now I'm *really* curious... How did you determine RPM of the spinning blades ? (252 +/- 25 RPM). Give the schematic Gordon and I gave you a go with your original blades. With a bit of luck it'll work. If not we have other options. The blades look decent to me, I don't spot any obvious errors. Then again I'm no blade expert. |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

OK.. I didn't use anything too high tech. first I calculated the the circumference of the shaft. (wrapped a string around it and took the length of the string. That's the easiest way.) Then I wound some string on the shaft and marked a point on the string. Then i help the windmill in the wind. As the windmill spun around the shaft reeled in more and more string. I recorded the amount of string reeled in in 1 minute. Then divided that value by the circumference of the shaft. Thereby I got the number of revolutions it took to reel in the recorded length of string. Keep in mind that whatever the number of revolutions ,they occurred in the space of one minute. AND THERE... we have the RPM of the windmill (or something very close at least. To get better results I did the experiment several times and took the average value of the individual results EDIT : "The + or -" bit was just guess work to allow for errors in the test how come its not very windy where i live??? |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Impressive  |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Excellent technique and one I am sure catapults you way up in the ranks of back shed experimenters!  |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

I can't help but think that the actual rpm is well less than what you have calculated. If the string layered onto another layer, your circumference measurement will be too small. ie you will have effectively changed the diameter of the shaft by increasing it with string.... otherwise you would have to have had enough shaft to neatly wind 250 turns of string without overlap.... (if the string was 1.8th inch thick, that would be 30 inches of shaft or more) If I am correct, your rpm will be significantly less. If you want to use the string to measure, then do the same experiment, but rather than unwinding and measuring, count the unwind turns and you have the accurate answer. If it is as I think, slow rpm, then either very little wind or blade stall may be the culprit still. Those blades at the diam should pull over 400 rpm in a 10 mph wind. As an example, my 4 meter blades do over 300 rpm unloaded in a 10mph breeze. .........oztules Village idiot...or... just another hack out of his depth |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

I see no benefit in the total number of revolutions in a minute and using this as an indicator of windmill speed. Speed is an instantaneous value. We use RPM as it is a convenient term. Angular velocity is more appropriate, redians per second, but most have trouble visualising it. All of my experiments show the wind is not constant and the instantaneous rpm of my mill can range from 10"RPM" to 100"RPM" in a 1 minute time interval. The linear average may be 55"RPM". We are interested in the instantaneous output voltage, as this dictates instantaneous output power and this is related to the angular velocity, and not the average rpm measured over a 1 minute timing period. I guess this relates to a literal interpretation of revolutions per minute. Gordon. become more energy aware |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

you are correct but the string didn't wind up onto itself. (and the shaft is pretty small just like the windmill so I didn't need a lot of string. the diameter is about 1 cm.) All the loops wound tightly net to each other so there probably would not be such a big margin of error. All that said, it is not 100% accurate but can give one at least a rough idea of the windmills RPM That's way above me.. I'm only 15 years old. I do get the idea of what you are saying though..(At least i think I do lol) the way i understand it RPM is an average value for the entire minute. Not the speed of the shaft at a given time. I am pretty sure the RPM remained constant though cos I also did the test in front of a fan as well (therefore constant wind speed) and got more or less the same results. (the whole thing took less than 10 secs) how come its not very windy where i live??? |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

Ok guys.. I sincerely thank you for all your help. adric22 KiwiJohn Dinges (thanks for the schematic) Piercy007 (who did you get the "007" part from? and thanks for the link to the stepper motor site) Oztules GWatPE THANKS!! I will post on another thread if I have any more developments on my windmill Oh.. by the way, I just noticed that there were posts from all the continents except South America, Antarctica and Africa. (that may be wrong.. my geography is a bit rusty). When you think about it that's pretty cool how come its not very windy where i live??? |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi mahela, was the test for a full minute, or less than 10 seconds? The reason it is not very windy where you live is related to the proximity of Sri Lanka to the equator. Gordon. become more energy aware |

||||

| mahela007 Newbie Joined: 06/07/2008 Location: Sri LankaPosts: 29 |

what I meant was the shaft took 8 secs to wind in one meter of string. How does proximity to the equator affect winds? how come its not very windy where i live??? |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Hello mahela007 I found this idea of using a cycle computer for RPM worth noting. http://www.reuk.co.uk/Use-a-Cycle-Computer-to-Measure-Turbin e-RPM.htm It may be safer than string,Good luck. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Hello again,I tried this link but you may need to retype the turbine part.Something got lost in the pasting or alternatively go to the reuk site and type RPM into search box.Computers aren't my thing. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Try this link to it Village idiot...or... just another hack out of his depth |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

The cycle computer is a simple solution. I used one of these to correllate windspeed to rpm on my mill. I was able to record max windspeed, RPM and unloaded mill voltage over a range of wind conditions. I then repeated the exercise with the loaded mill and maximiser. These all happened to have linear correlation, so I now only need the mill voltage and the factor to get RPM. Other systems will probably have a different relationship loaded, but unloaded will be similar. Gordon. become more energy aware |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |