|

|

Forum Index : Windmills : Pole bending tool

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

After recently speaking with Gordon, who has twisted the poles on his F&P with excellent results, I wanted to give it a go. Jarbar describes how he made a pole twisting tool using a mill on this page here, but I dont have access to a mill or router suitable for steel, so I tried a different approach. 13mm RHS ( 1/2 inch box ) is almost the same width as the stator poles. I grabbed a length about 300mm long, and fabricated the two grippers from some 3mm flat mild steel. Each gripper has a bend at each end and are welded to the sides of the RHS, about half way along. Then I used a file to chamfer the edge as shown so when you twist one pole it clears the other two each side. When I first tried it, it was a tight fit, but a gentle tap with a steel chisel on the inside edge gave the clearance to fit neatly over the F&P poles.

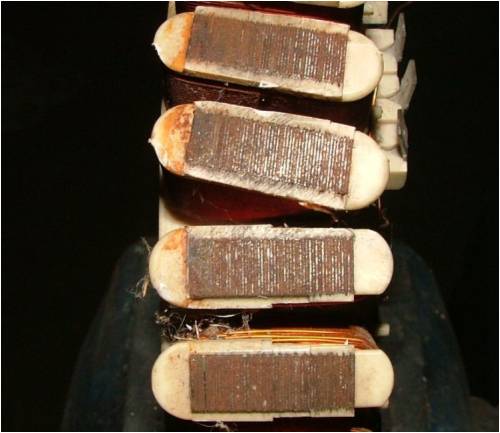

This is the result on a dead stator. Bottom two poles are original.

I was surprised how easily the poles bend, really no effort at all once you have the tool. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Glenn, Good to hear another way other than a milling machine. I can't see how it fits. Does it grip the steel laminations? If so how do you work around the plastic encasing them? Or does the tool press against the plastic? was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Gill The RHS sits against the face of the pole ( where the laminations poke through ), the grippers press against opposite corners of the face. When rotated, the grippers press against the plastic corners of the pole. The grippers are only about 3 mm deep, so there is no chance they will press against the coils. Once in place, I pull on one side and push on the other to twist the pole face around, easy as. These pics might help, I've painted it since the last photos.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Glenn, This is a little more elegant than the bar of an F-clamp that I used, just pushed down between the poles. How much dressing of the pole faces was needed to get clearance on the rotor? The amount of angle you have will reduce the cogging a heap. Gordon. PS edit: The bar I used was smooth sided. None of the enamel was damaged on the windings during the bending process. I did not rush it, which helps as well. become more energy aware |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Does it make a difference if you twist the bar clockwise or anticlockwise?

Sorry, just had to ask.....  Klaus |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Gordon. Haven't dressed the pole ends yet, this was just a test run. Will do a whole stator this weekend. Hey Tinker. It depends if you live in the northern hemisphere or southern hemisphere

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| robbo Regular Member Joined: 25/03/2007 Location: AustraliaPosts: 71 |

So how much less resistance is in the laminations now ? Ie, how much easier is it to turn ? Is it easier than a 7 phase setup ?  "the Earth was not given to us, by our fathers, rather, it is lent to us by our children". |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Robb I have some measured results posted here under topic Decogging F&P my comments are on the 4th Feb 2008 on page 3 of the topic Herb ps never bothered with further testing due to lack interest in results and method I have used on my Mill tho since then. |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi herb, the reduction in cogging torque you measured is more than I measure. Mine were not twisted as much though. I expect the best result will be when the poles almost overlap. This point is when you get the cracking sound during the twisting process, when you thing it is broken. Gordon. become more energy aware |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |