|

|

Forum Index : Windmills : another newbie question

| Author | Message | ||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

hey so how do i find the three hot legs from my new 3 phase motor? it is seized too. not sure if that is from the encoder (electronically seized, or mechanically). back to the hot legs. so i took of the encoder cover, and removed the encoder, but am lost. thanks!

http://i118.photobucket.com/albums/o112/adrock8/c-list003-1. jpg i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Some servo's have an electric brake. This needs power to release. Its usually at the opposite end of the motor than the encoder. Keep the encoder, it will come in handy or could be sold on ebay. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

I would bet my left testicle the black plug, with the yellow and black wire, at the bottom of that photo goes to the brake. Pull the motor apart and follow those wires to the brake unit, which will need to be removed. Be carefull of the magnets. The brake is used as an emergency stop if power is lost or someone hits the big red stop button. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

thanks glenn! i will dig into the motor after work. do you think the three power wires come into the plug shown at the far left of the picture? there are nine pins in the plug. i removed the encoder and it has a keyed connection to the motor. the yellow and black wires (mentioned by you) turn into two orange wires before they enter the encoder. there are two wires exiting the encoder (red brown) that wire nut to two white wires that run back into the motor. there are not any other wires entering or exiting the encoder (other than the wires that run directly to the larger plug on the encoder cover) still willing to bet one of your boys that this wire assembly is attached to the electro brake? was about to take a pic of this, but camera needs battery charging. sorry. will try to get one up after work. the shaft does have a tiny bit of play it it. i can turn the shaft back and forth maybe like a 1/50th of a turn. thanks again! can't wait to begin carving blades for this contraption! posted a previous post about this motor, and my attitude has changed about getting a possible 240 watts. i will be really happy to obtain anywhere near that amount of power from this genny. i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi birdhouse, There is unlikely to be a mechanical brake within the unit you have. The 2 wires are most likely for a temperature sensor. I would think that a likely scenario is a magnet has come loose from the rotor. These units are used in Industrial Robots. I have several Pacific Scientific brand units. I would not try and turn the motor. Just disassemble and check the rotor. These usually have curved SmCo magnets. Overspeed and temperature can loosen the magnets. You should be able to fix this. The bearings may be siezed, and this will still require disassembly to fix/repair. Gordon. become more energy aware |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

thanks everyone! so i got home from work and took every visible fatener from the motor. even the "c" clip from the front of the shaft. i was able to get the case to crack open about 1/8 inch about halfway down the motor's length. i think i need a bigger hammer. this thing does not want to come apart! GWatPE- i don't think the bearings are locked. they are all shiny and new looking, in fact, i don't think this motor has ever been used. hard saying. i'm gonna keep prying and banging unless anyone has any better ideas. thanks i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Please dont use a hammer.....

Have you taken off the red encoder, it will be attached to the motor shaft. These are very similar to the robot servo motors I have. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

gizmo- yea, the cap and encoder are off. all fasteners are off. i'm wondering if a broken magnet is wedged in the housing making it impossible to take apart with out shattering the magnet?? i have only been using a rubber mallet so far. thanks i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

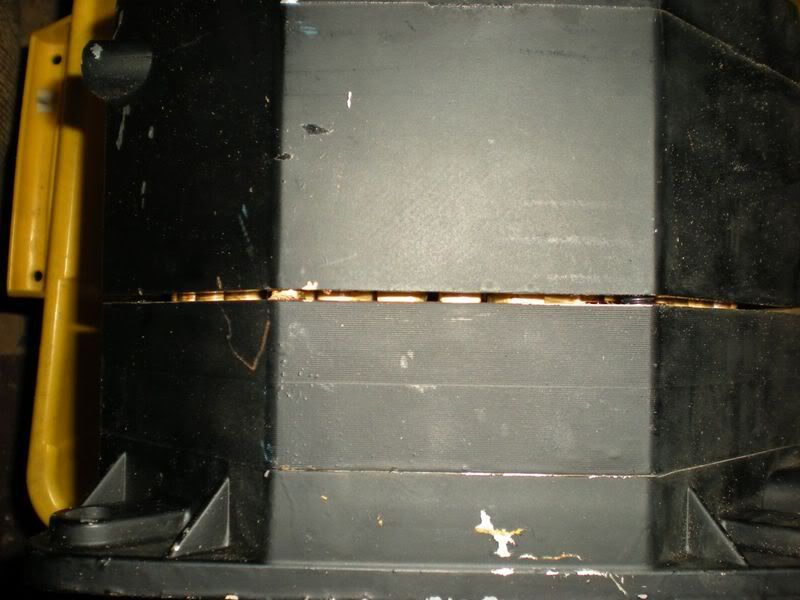

photo of progress....  i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

so i figured it out. got the motor in two pieces! yay. so the stuff on the left is the rotor with magnets, and on the right is the motor's brake. the two are joined via the spline/cog fitting. there is a pertinent bearing on the right side, so i'm not sure if i have to remove just the spline part to negate the relationship between the motor and brake, or if i can remove the whole brake and maintain the bearing behind it.  i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi birdcage, I stand corrected. There is a brake, that seems to be released when power is applied. Are there seperate power leads for it? It is likely the unit was purchased and someone thought it was broken, so sold it. Looks in good condition. Will make a good alternator for a windmill. Gordon. become more energy aware |

||||

| hoodlem Newbie Joined: 02/07/2008 Location: AustraliaPosts: 7 |

servo motors cost big bucks, you could sell this one on E-Bay and be able to buy heaps of second hand F&B motors. Do a search on the serial number to get an idea of what its worth free information for all |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

thanks for all of your help! i removed the brake cogs (on the right side of the photo. they seem to be made from silicon carbide or ceramic. not sure, but it was really light and has to be strong to brake the motor. the bearing is still in tact and atached via a different bolt pattern from the brake... so that is good news! i just have to bolt the thing back together (without the braking cog) and now have a good windgen motor. GWatPE- it is birdhouse, and you made a mistake! totally kidding, everyone makes mistakes and i always forget peoples names. thanks for the help though! hoodlem- i bought this motor off ebay specifically for a wind gen and don't want to sell it. this exact motor goes for $6,000 us new and costs $3,000 to rebuild. the one i aquired seems to be new and i really want to see how it does as a wind genny. 2,000 rpm 20 amps 140 volts (3phase) thanks again for all of your help!! i will let you know once i've got blades made/purchased i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

sh*t i almost forgot- gizmo, you owe me your left nut. those two wires run to the stator. i think they are for an rpm/positioning gauge or a temp sensor as someone else pointed out. so cut one off and send it this way... kidding. peace all i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

*message removed* |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Its in the mail. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |