|

|

Forum Index : Windmills : 60dc-7s-2p star/delta Photo test

| Author | Message | ||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

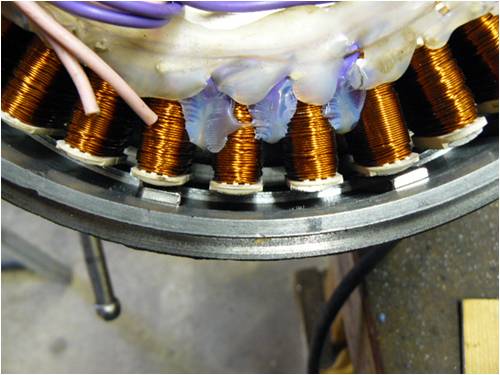

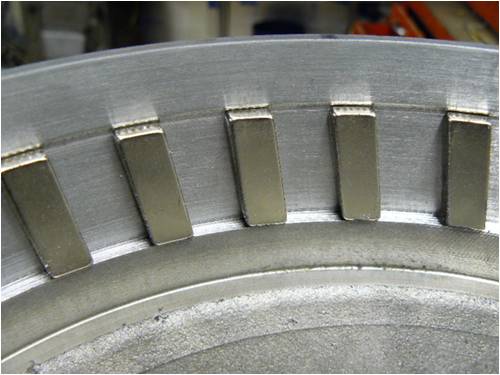

OK all you mill heads out there I finally got some work done on my mill and would like to post a couple of photos to see if they come out ok? Basically I am using a 1750 lbs spindle and cast iron drum. So if the photos come out OK I will post more info. Photo Test

Jim |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Wow! You do nice work! :O) Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Not wrong. It sure looks strong. I'm a big fan of over-engineering, making something stronger than it needs to be. Its good to see such a well made machine. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

The only reason I am able to do any of this work is because of this forum and of course the members of Back Shed. The drum, spindle design is not mine it is from Gordons posting of his mill. I didn't make the spindle I just modified it to fit the stator. I bought the stator rewired. I did had to machine a grove in the drum to fit the neo magnets which I haven't installed as of yet but the magnets I did install makes the stator difficult to spin hopefully when all the magnets are in place clogging will not be an issue but I get this feeling it will. The winds I get here can blow down tress and tear the shingles off of roofs so I figured it better be strong. The yaw bearing assembly follows Huge Piggotts water pipe design only instead of use washers as bearings I will be using a Torrington thrust roller bearing the kind used in automobile automatic transmissions. I machined the bearing mount my self.

Jim |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |