|

|

Forum Index : Windmills : 25th Feb 2006. Windmill swap.

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Well it happened, the yearly wind change. For the next 6 months the wind will be blowing from the south east, and I live on the north west side of a hill.

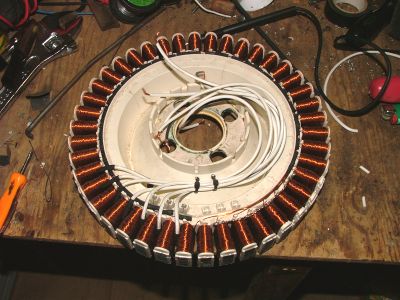

Last year the HAWT didn't move once for months, thought I remember the Lenz windmill on its stumpy little 7 foot tower was running every day. So this year I decided to take the HAWT down and put the Lenz up in its place. Even if it only made a few watts, at least it would be spinning around and looking the part. First up, since this Lenz is a low RPM machine, I re-wired a 60 series stator as a 7 phase cogless 6 pole. This will give the best voltage at low RPM, and a 7 phase conversion means no startup or running cog. Startup cog was never a problem for the Lenz, but the cogging did make a lot of noise in those big wings, so I figured a cogless F&P would work better.

On Sunday I droped the tower and removed the HAWT, then fitted this bracket to take the Lenz. I wanted to keep the mast head intact so it would be easy to refit the HAWT when the winds return in September.

Here is the F&P stator and Lenz struts in place.

And all together. There was a bit of weight in it all, the tower was starting to bow.

And up in the air.

So fars its going good, I had the PicLog windmill logger on it today to get some readings, very little wind, but it still made 14 watt hours for the day, and peaked at 22 watts a couple of times. Remember this is only a small windmill, 1.56 meters square compared to the HAWT's 3.8 meters squared. The HAWT would have made no power at all today. Over the next few weeks I'll keep the PicLog on the Lenz to get some figures. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

A very nice machine ,Glenn. I've some curved steel tube ready and will start on making one soon. a bit frustrating when we look up and see these efforts sitting idle ,I know. cheers Bruce Bushboy |

||||

rotorhed Newbie Joined: 29/01/2007 Location: AustraliaPosts: 36 |

Hi Gizmo Just had a squiz at you diary post. It makes me all warm and fuzzy inside to see that when the hawt fail the vawt is still kicking. I would love to see the results from your Piclog when you've finished data collection. That Lenz of yours just looks fantastic

Cheers Christian Marge the Winds are here Ah McCaine............. |

||||

| gonzo Newbie Joined: 18/02/2007 Location: AustraliaPosts: 6 |

hi, your lenz looks great why does it make noise i am thinking of building a savonius mill with car diff out of three forty fours to generate top up power for a solar set up with star wiring f/p would delta be better? site is in a valley would lenz be better? low mount ie four metre tower only site is not mine i visit three times a year so the best i could bring would be preferable very low maitenance power is what i'm looking for any help i could get on all aspects will be welcomed |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Gonzo The F&P vibrates as it rotates, cogging we call it. Or at least the standard 3 phase version does, the new 7 phase version has no cogging. When I first built the Lenz2 I used a 3 phase F&P, and the cogging vibration went up the drive shaft and into the wings of the Lenz. Now these wings have a large surface area, and they acted as speakers, radiating the vibration from the F&P. So it made a very loud drone noise, a bit like a 4 stroke motor bike. A 7 phase or decoged 3 phase F&P gets rid of the problem. You might find this link interresting, http://www.southcom.com.au/~windmill/, its a site by Ken Sulman who has built several savonius windmills. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| gonzo Newbie Joined: 18/02/2007 Location: AustraliaPosts: 6 |

thanks glen i ride a four stroke so i like that noise however as the mill will not be in my yard noise is a no no. ive already checked southcom nice water tank but i think the wheelbarrows would look better with wheels & handles. wing design from california energy commission www. energy.ca.gov/2...5-084/cec-500-2005-84pdf also looks good TSR 1.6 vertical vanes to direct airflow also worth considering will keep looking and make a couple of model variants while i gather all parts for rig thanks for your help Fixed that link for ya, Glenn. http://www.energy.ca.gov/2005publications/CEC-500-2005-084/C EC-500-2005-084.PDF |

||||

| thefinis Regular Member Joined: 23/08/2006 Location: United StatesPosts: 53 |

Skimmed/read that doc and wonder how much it cost per word to come up with that. If I read it right the best design was with 0 overlap and no slots. It sounds a lot like a meat tray rotating kite design (same class as a UFO kite). They work on the Mangus effect to generate lift. The kite boys found that the curved S design turned slower than a flat piece with angled flaps on the outside edges. I will have to try a blade designed like that when I get my test tower hardware welded back together. I used around 25% overlap on my S rotor which to me seemed to make the best use of materials and provide enough crossflow to boost power. Offset each set by 60 degrees and used sets of 3 to even out the torque and lower vibration. Tried 3 halves on same level but no crossflow saw a drop in power even with it having a little bigger diameter. Saw a design recently that was a big vawt that had an outside tower with fins to direct the windflow and it sat on top of the power room with the generator inside. I like the idea of turning the tower into something more than support for a vawt because I think that as you get very big/tall it will need a support point with a bearing at the top which means an outside tower or some fancy rigging. Finis Texas born and bred |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |