|

|

Forum Index : Windmills : F&P output data

| Author | Message | ||||

| carl1 Regular Member Joined: 16/04/2007 Location: AustraliaPosts: 79 |

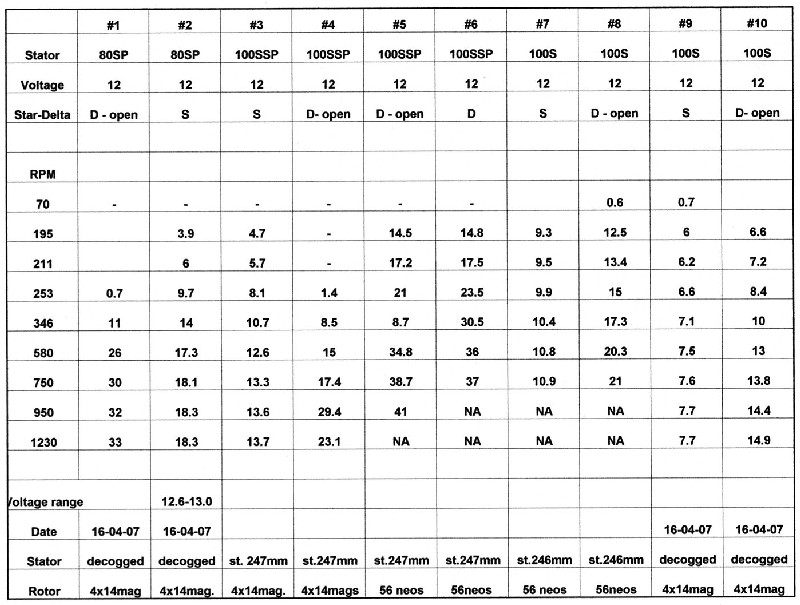

here I go again. I have printed and scanned it as jpeg.

#1: decogged,rotor 4x16mags, rectifying each leg separated via 6 pair of diodes, I call it open delta. #2:decogged,rotor 4x16mags, star rectifying #3: 100SSP- each phase 7poles in series and paralleled, stator OD reduced to 247mm with an angle grinder. star connection #4:100SSP- each phase 7poles in series and paralleled stator OD reduced to 247mm with an angle grinder. rectifying each leg separated via 6 pair of diodes , I call it open delta #5: 100SSP- each phase 7poles in series and paralleled stator OD reduced to 247mm with an angle grinder. rectifying each leg separated via 6 pair of diodes , I call it open delta rotor: 56 neos, I replaced the first generation rotor mags (56single mags) with same size neos angled them about 20degress. #6: 100SSP- each phase 7poles in series and paralleled delta connection stator OD reduced to 247mm with an angle grinder. rotor: 56 neos, I replaced the first generation rotor mags (56single mags) with same size neos angled them about 20degress. #7: 100S - star connection, rotor: 56 neos, stator OD 246mm #8: 100S - delta open, rotor 56 neos, #9: 100S - star connection, stator decogged, 4x16 mags #10: 100S - delta open , stator decogged, 4x16 mags NA: the lathe could not start it. One interesting info here is you don"t need a complicated star- delta switch to change over just recify via a pair of 3-phase rectfier ( I used a pair of car alternators) In star you don't connect the phases together and to switch from star to delta you just need an ordinary tripple switch- opening the star connection. Harald

|

||||

| carl1 Regular Member Joined: 16/04/2007 Location: AustraliaPosts: 79 |

Here are some more results:2007-04-19_203225_Smartdrive_data_#9.zip |

||||

| carl1 Regular Member Joined: 16/04/2007 Location: AustraliaPosts: 79 |

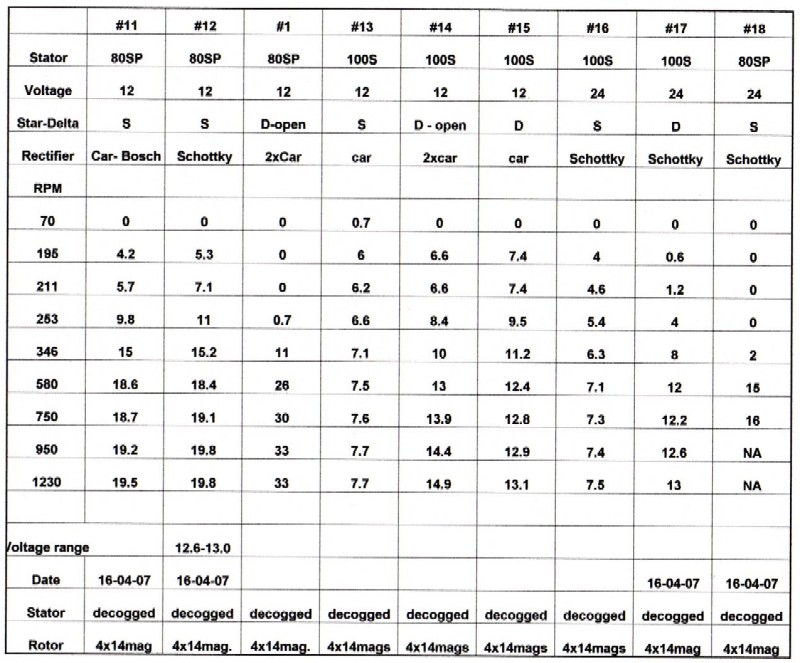

Looks like the Zip file didn't work. here is it as a picture:

Harald  |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello Harald,, thank you for the work above ,well done . Looks like #5 would be the best allrounder??. I'd like to see and know more about the way you made your Neo Magnetic Rotor,? please. I made 2 and the first one works very well in a decent wind ,the other is a failure because of the spacing I made in attaching the Magnets --too wide by ,say,1mm. -anyhow next time!!. Thanks Bruce Bushboy |

||||

| carl1 Regular Member Joined: 16/04/2007 Location: AustraliaPosts: 79 |

Hi Bruce Re; Neo rotor; I used the one with the 56 single mags, chopped the mags out and used the markings in the plastic to position the neos even. I will post a pic later( couple of weeks)- i don't have it here. I will test the 100SSP on a 24 volt rectifier with 12 Schottys - this will be interesting. The stator, I have ground down the OD with a angle grinder, there might be even a better output machined down on a lathe. Start up torque on the neo rotor is 2.5 Nm , the same as with the original one (4x16mags). For 12 volt I think the 80SP with switching from star ( low speed ) to open ( each phase separated rectified 12 Diodes I call it D-open )is a good option, anD for switching there is only a triple single pole switch required- no star delta switch! Harald  |

||||

| carl1 Regular Member Joined: 16/04/2007 Location: AustraliaPosts: 79 |

Hello to everybody: First some correction in the tables for output:

#4, 100SSP, rpm@950 must read 20.4 #5, 100SSP, rpm@346 must read 27 #14, 100S, rpm@211 must read 7.4 #15, 100S, rpm@211 must read 7.1 I did some more test: 1: regarding shunt regulation: I did a one hour test run on an 80S unit without being connected to a rectifier at 1200rpm: The temperature of the laminats ( steel core ) rose to about 60 celsius, coppercoils did not heat up. seems to me like you could run it disconnected from the rectifier without any damage. But watch out for the open voltage at the connections. I measured 580 volt with an 80S-star- @1200rpm and 85 Volts with an 80SP-star- @1200rpm. The output of the 80SP-star one phase disconnected from the rectifier was reduced by 50%: @1200rpm 11amps. I changed the rotor from a grey one to brown one: The brown one had 1.3 to 0.8 amps more output.- 80SP -star. Looks like magnet strength varies a bit. cheers Harald |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |