| Author |

Message |

Gill

Senior Member

Joined: 11/11/2006

Location: AustraliaPosts: 669 |

| Posted: 03:46am 26 Apr 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

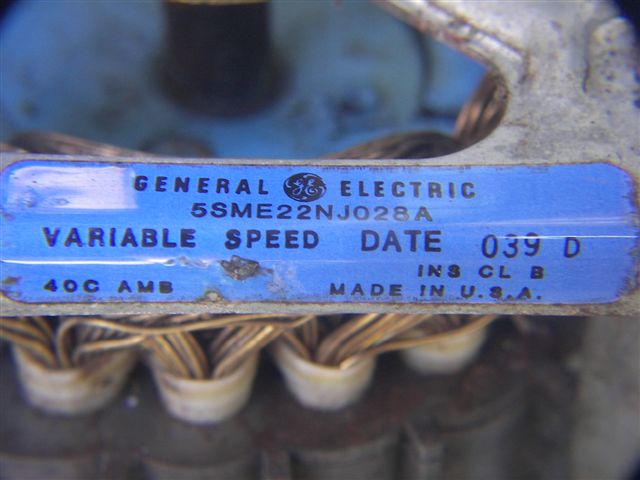

Here are some pics of a PM motor I stripped from a more conventional F&P washing machine some time ago.

It is a General Electric, permanent magnet type, 3 phase Star, and I'm guessing 2 speed.

I did not take down the model number though.

It had step down gearing to the main shaft via one of those flat-grooved belts.

Cogging is not excessive at about the worst of a smartdrive by guesstamation.

Thought perhaps it would be more suited to a waterwheel or perhaps vawt application.

Any ideas or background history appreciated.

was working fine... til the smoke got out.

Cheers Gill _Cairns, FNQ |

| |

brucedownunder2

Guru

Joined: 14/09/2005

Location: AustraliaPosts: 1548 |

| Posted: 08:58pm 26 Apr 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hello Gill,

I have 3 of these motors,I think they were referred to as the "Gentle-Annie" type F&P motors(made by??) ,.

I bought all the leads out and tried different combinations on the test bench,years ago, but from memory didn't go much further.

They are still wrapped up and one day ,I'll set one up again ,as I even made a welded up steel frame .

I cut the grooved pulley off lengthwise,it then springs out a fraction and you can pull it off easy without damaging the shaft.

They are a bit "coggy" ,but as with the new F&P once started they offer no cogging.

I pulled the magnetic rotor out of one and dismantled it . Nice 3 semi-circular ceramic magnets that are bound with very fine steel wire,don't know much about that reason>

Cheers

Bruce

Bushboy |

| |

brucedownunder2

Guru

Joined: 14/09/2005

Location: AustraliaPosts: 1548 |

| Posted: 11:01pm 27 Apr 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Bye the way ,,, those windings are Aluminium. So you have to be fairly clean and make your connections tight . , if you decide to seperate the configuration into some other connections. It's best to try and leave the factory fitted copper fly leads as they are .

Bruce

Bushboy |

| |

Gill

Senior Member

Joined: 11/11/2006

Location: AustraliaPosts: 669 |

| Posted: 01:59am 28 Apr 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Ahhh! They're Aluminium! I didn't know that.

That's given me something more to ponder on.

Tnx for all the info Bruce.

Just wish I had a lathe to do some testing on outputs.

I'm cautious of stripping it down as I suspect there is little, if anything, that can be done to make it more suitable. That belt drive might be just the thing needed for a waterwheel idea i've been toying with. Would hate to cut it off to get inside only to find it was best left as is.

was working fine... til the smoke got out.

Cheers Gill _Cairns, FNQ |

| |

Feral

Newbie

Joined: 03/12/2006

Location: AustraliaPosts: 39 |

| Posted: 01:40pm 28 Apr 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Gill, The blue rotor which appears to be in three sections also has eight poles,4 Nth,4 Sth, if that is of any interest and I would guess that the wire around the outside is not steel but another non magnetic metal bound to hold it together.

The shaft also presses out of the centre of the rotor and if you were prepared to rewind in copper it could make a good little 3Phase genny.

I had a complete motor but I am only left with the rotor and now looking for an AC motor the appropriate size to install it in. |

| |

herbnz

Senior Member

Joined: 18/02/2007

Location: New ZealandPosts: 258 |

| Posted: 04:50am 29 Apr 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi These are Gentle Annie motors. I have used extensivly for 12 years now. However on hydro plants they infact would produce 90% our power. Need high revs >1200 rpm two separate windings one low voltage internal star the other windings bought out separatly can connect delta or star. very efficient at low power levels only 10W no load loss at 3000rpm. can dismantle with grinder on little tags easy to re wind to any voltage. bearings can give problems. Can give heaps more info for those interested but not suitable windmills because low revs also existing windings limited to about 5 amps,

Cheers

Herb |

| |

maaca

Newbie

Joined: 21/11/2006

Location: New ZealandPosts: 22 |

| Posted: 07:52am 03 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

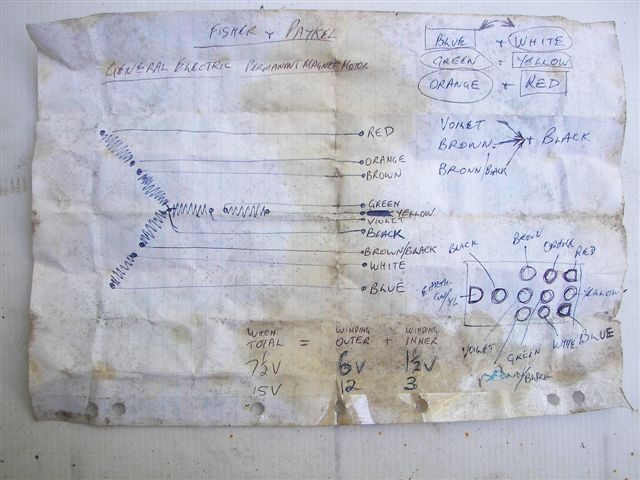

Hi Gill from the brown terminal block remove orange, white, and the green, colured wires[not green and yellow] and join together.This is your star connection. Remove red, yellow, blue,. These are your three phases and then go from there.I will be commisioning my first attempt in 2-3 weeks using one of these on a 1.2m prop. Dont expect too much from these little motors but at low revs on my lathe it gave 1.25 amps. at 30 volts.Five amps would be an absolute max but my lathe didnt give enough revs to get up this high. I did get up to over 100 volts but dont remember the amperage. Good luck. Maaca. |

| |

Gill

Senior Member

Joined: 11/11/2006

Location: AustraliaPosts: 669 |

| Posted: 10:15am 03 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Thanks fellas,

Appreciate all info.

From the comments, I think I would be inclined to connect the inde windings in Delta. Rectify that,then series that DC with the rectified DC star windings. No problems doing this as all perfectly synchronised. Achieves somewhat more amps whilst maintaining volts. Shame to waste windings and a bit more grunt for the mere cost of an extra bridge?

Please let us know how your Gentle Annie goes Macca.

The more info the fewer pitfalls. Ta.

was working fine... til the smoke got out.

Cheers Gill _Cairns, FNQ |

| |

herbnz

Senior Member

Joined: 18/02/2007

Location: New ZealandPosts: 258 |

| Posted: 12:58am 05 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi re connecting in delta Iavoid this unless I know I have Sinewave.you get exactly the same effect by having the windings as three single phase with their own bridge only penalty is cost of third bridge that it seems most ppl use at anyrate.Also easy to change star by shorting out one end of each winding.Delta is a short circuit to the distored part of a sinewave

Herb |

| |

Gill

Senior Member

Joined: 11/11/2006

Location: AustraliaPosts: 669 |

| Posted: 02:15am 05 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

G'day Herb,

I mostly know what you are saying, at least up until the last sentance.

Firstly, why would you not have sine wave in the first place with this generator?

When you are wired in Inde (independant)as 3 of these phases are, your choices are Star, Delta or OpenDelta (a term coined by carl1 on this forum that refers to independant phases connected in parallel and having the same output charestics as Delta).

I have a feeling that OpenDelta may overcome circulating harmonics if they are present in Delta, though I have no hard evidence to back this up. I also feel that circulating harmonics are largely but not exclusively caused by rectifier switching as commented on by Dr.Chalko but once again I can not qualify this theory.

Perhaps these are the same positive effects you also promote?

This business of shorting out 3 legs of each phase in OpenDelta to make Star doesn't seem right to me. You are leaving the neutral point still connected to the bridge(s). Surely you are still in OpenDelta with one leg having a tripple parallel path of 3 diodes. What benifit does this achieve exactly??

As to your last sentance, well that just looses me. Sorry.Edited by Gill 2007-05-06

was working fine... til the smoke got out.

Cheers Gill _Cairns, FNQ |

| |

herbnz

Senior Member

Joined: 18/02/2007

Location: New ZealandPosts: 258 |

| Posted: 09:33pm 05 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Gill

Ok the waveform produced by these motor come generaters is not a sine wave they ar designed with the idea of being driven by pulses no need to consider waveform. Infact the flat toped waveform that can be observed on a scope is great for what most want battery charging. Any waveform that is not a sinewave as i detect you seem to know can be represented as a fundemental sine wave in combination with waves of multiple frequency harmonics. in a closed delta the odd harmonics find the closed delta a short and circulate a fact used by power suppliers to filter out harmonics.This was what i refered to in my last sentence trying not mention harmonics etc.

Ok the open delta means we can use these on the dc side.

Right the open delta conected through their three bridges can be converted to star ideally by disconnecting one end of each winding from the bridges and creating a neutral point by shorting them the bridges will be be connected as a fullwave three phase bridge. One day while doing this I forgot and shorted with out disconnecting no problem i investigated with meters in connected wires no currunt flow. I have since sat down and drawn vectors and yes the phases cancel out so does work without disconnection. however best to use a change over switch that disconects then shorts. |

| |

herbnz

Senior Member

Joined: 18/02/2007

Location: New ZealandPosts: 258 |

| Posted: 09:41pm 05 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi again looking at it again i see a problem using term open delta better use term indepentant connection. I know of one person that actually opens the delta one point with the windings connected correctly there is no volts (good test method ) if you reverse one winding you get exactly two times phase voltage. Its not a good idea but does work.

Herb |

| |

Gill

Senior Member

Joined: 11/11/2006

Location: AustraliaPosts: 669 |

| Posted: 04:27am 06 May 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Thanks Herb

Much appreciate the reply. I understand all you have said now. But I'll leave those gimic connections to others as I feel that for every 'Wow' factor there has be a balancing trade off and a resultant drop in overall power, and I don't need that.

was working fine... til the smoke got out.

Cheers Gill _Cairns, FNQ |

| |