| |

Page 2 of 2 Page 2 of 2 |

| Author |

Message |

Bushman

Regular Member

Joined: 24/04/2007

Location: AustraliaPosts: 41 |

| Posted: 10:59pm 17 Jun 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

G'Day Highlander

Thanks for the positive comments - yes, as suggested by Gill, we'll increase the tail size significantly. The blades were a prototype set cut from a single length of 150 mm UPVC and I'll accept the advice that they need to have a bigger area.

The clutch plate because it was found unidentified at a wreckers and just happened to fit. I think it is Hyundai but I.m really not sure. Anyhow, it is not an ideal solution because you can't drill the spring steel and that is the reason the blades are aligned the way they are - the bolts had to work with existing holes. The next one will use a splined pulley wheel that can be drilled as needed for better blade alignment

The stator has been rewired into three phase and no, I'm not planning to test it on the traier - it was stuck there just for the picture. A serious mount has been made from lengths of Acro props bolted together on a swivel base Dynabolted to a concrete pad and guyed with adjustable wire stays

Although the lads insist the two pictures above have clockwise rotation while mine is anticlockwise, I am dumb enough not to be able to see any difference. For example, each blade pointing downwards clearly has the leading edge on the right side. This includes my unit though it may not look that way because of the light reflecting off the paint.

Assume I'm stupid, but in any case, I do not understand why the blades need to rotate in one direction or the other because it is generating AC - not DC.

If anyone can help clear this up, it would be appreciated

Cheers

Alan |

| |

Storm

Regular Member

Joined: 12/09/2005

Location: AustraliaPosts: 43 |

| Posted: 12:24am 18 Jun 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

You could weld a larger steel disc to the clutch plate and then attach your blades to the disc avoiding the springs etc, to me it looks like your machine uses a clockwise rotating prop as the wind will push on the root of your blades this way and yes it doesn't matter which way the alternator spins output will be the same.

look from your tip towards the hub, imagine the wind hitting it.

|

| |

Bushman

Regular Member

Joined: 24/04/2007

Location: AustraliaPosts: 41 |

| Posted: 12:35am 18 Jun 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Thanks Storm - exactly what I thought would occur. Welding a larger plate to the clutch assembly is a good idea - will probably do just that to modify this prototype - and increase the blade width at the same time.

For the next unit though, I shall not use a clutch plate because of the ripoff prices charged by wreckers or the problem of having to sort through a mountain of parts just to find the right spline. Pulley drive wheels are much easier to find cheaply, the centres can easily be reamed out and most have a flange that takes a lock screw onto the FP shaft. Going to say, a 250 mm diameter also makes it easier to secure larger blades

Cheers

Alan |

| |

Highlander

Senior Member

Joined: 03/10/2006

Location: AustraliaPosts: 266 |

| Posted: 09:15am 18 Jun 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

G'day bushman, nah doesn't matter which way it spins as far as generation goes, I'm not sure but I don't think it will effect furl angles.

See if you can get some 300mm pipe like the ones Bruce made. The profile seems to be better.

I think Bruce has a twin stator unit so yours don't need to be that long.

I would consider the 7 phase as the start wind speed will be reduced by a lot.

But this means buying a new hub, I think the guys were paying around $50 or so.

That's a different way of making a base, never thought of that. A lot simpler than mine.

PS have you decogged the stator? It's a good idea for 3 phase as the start cogg will be reduced but you'll lose 2.5 amps I found.Edited by Highlander 2007-06-19

Central Victorian highlands |

| |

brucedownunder2

Guru

Joined: 14/09/2005

Location: AustraliaPosts: 1548 |

| Posted: 09:40pm 30 Jun 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

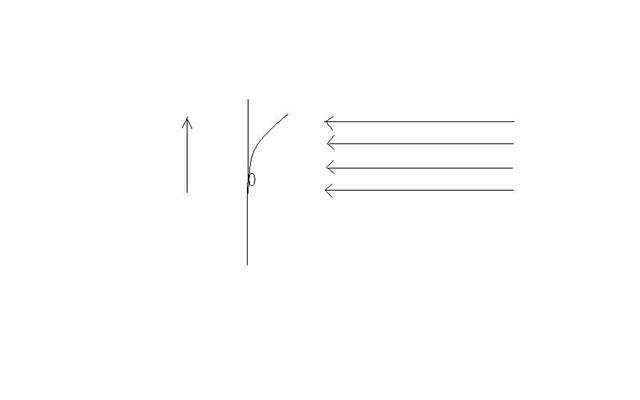

Thought I'd bring you up on the progress of these 3.5 Mtr diameter ABS plastic blades.

I've set them out on the concrete floor and drilled and bolted them as accurate as possible ,tip to tip.

One blade took on a curved shape after I cut it from the pipe-dunno why , but I'lltake to it with a heat gun and see if I can gently persuade it to come back in line with the other 2 blades ,for more accurate tracking.

Balance wise ,they are perfect, these blades spin on a breath of wind.

Edited by brucedownunder2 2007-07-02 Edited by brucedownunder2 2007-07-02

Bushboy |

| |

brucedownunder2

Guru

Joined: 14/09/2005

Location: AustraliaPosts: 1548 |

| Posted: 09:47pm 30 Jun 2007 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Sorry,had a problem with posting the pic ,,but it was me.

It's up there now .

BruceEdited by brucedownunder2 2007-07-02

Bushboy |

| |

| |

Page 2 of 2 Page 2 of 2 |