|

|

Forum Index : Windmills : Producing F&P

| Author | Message | ||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Vasi That website very interesting took a while scout around to discover its in your country anywhere near ? Yes we need to explore their products that stator pole is very interesting its disigned for conventional outer stator if we used FP rotor we want inner but may be able to use upside down I will look closely at dimensions can you approach company see idea prices soft magnetic products you might be in right place after all hey nice one. Windman you have done what I have only armchair dreamed of I would love more info where did you get the magnatite powder ? is not magnatite not a hard type magnetic material used to make first magnets. ? if so it would have a high hysterisis loss. but casting the powder in epoxy sounds great. tell us more please herbnz |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

They are not near but I can contact them on email. Look to dimensions and products and send me an email f u n l w 6 5 (a t) g m a i l (d o t) c o m - no spaces - and I will contact them to know the prices. I know they can make new products on command, custom dimensions. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| windman Newbie Joined: 02/12/2006 Location: Posts: 19 |

I thought magnatite would be hard to find , but living in the world best quarry has its advantages.its mined in NSW and I purchased a 20kg bag for about $20 from Australian Minerals here in Adelaide, that was a few years back did not use all of it because i went on to punching out steel lams |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

herbnz, you saw this? http://www.windstuffnow.com/main/poured_stator.htm Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Also I found this (in my country) :

"Cutting Dies for laminations for electric motors and transformers"

Where D = 30-600 d = 10-400 I think is about "cm" Address: www.electroputere.ro Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Vasi That site is showing it can be done many thanks I am still digesting the info I would like a bag of the iron powder to try i will ask you to approach ur manufacture soon i would also like to see if they can economically produce a small brick shaped peice that i can build up into a stator at this time i have not got the measurements worked out. Herb |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

No answers yet from Rofep. I don't know why, in past I had answers from them. Please give me the dimensions. I will send them a letter. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hello Herb, I have a reaction from S.C. ROFEP S.A. : 1. Prices for iron powder products depends on complexity, weight and performance. 2. They accept customer demands. The molds for custom dimensions must be supported by clients (clients must pay for them). Here is a letter from General Director Adrian Iliescu 2007-06-19_214306_letter.rar So, maybe is a good idea to make a project for entire TheBackShed team . I think iron powder stator for F&P is great . Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hello Herb, I have another response from Rofep S.A. They sent me another letter with prices about iron powder pot cores, and toroidal cores, this page. They sent prices for actual production. For custom dimensions and shapes we must pay the mold. They wait for our response! Prices are without VAT. We get the prices for new dimensions and shapes after we send them the details. I will buy a pot core or two to maintain the gates of Rofep open. Translation romanian/english: tor metalic = toroidal iron (powder) oala metalica = iron (powder) pot cores 1$ US = 2.3926 Lei (2.39Lei) What can I do? I will post the letters also on romanian forums to find someone interested (to cover us  ). ).

2007-06-21_002431_letter2.rar Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Vasi You are doing great I have not been able to read letters yet need download software. but will at present there never seems to be enough hours in the day. I liked the idea of the cast stator you found one of the things I would like is to see if the factory would supply some raw powder. Yes I believe we should come up with a shape My mind is seeing a simple brick shape that we can stack around a former one inner ring continuous then stack and glue another ring with spaces for the windings and spaced to suit the FP rotor. I will need to drag my old books out on magnetic calculations. Basicly I know the Ampere turns that the FP rotor has by the amps it demagnetises the present poles all I need to do is check the magnetic characteristics of the iron powder to see if we can get a suitable pole size. I know that this will improve the output at the higher RPM also will give use a stator that we can fabricate at home easily with different configarations yet still utilise the standard rotor although if u can afford Neo magnets the use of brake drums is also open Cheers Herb |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hello Herb, thank you for response. The latters are .pdf files, rar archived (WinRar 3.70 by Eugene Roshal). Maybe Glenn can help you. I don't think they can send you raw powder because can get rust. But I will tell them about ... So, anyone can get involved on this? Anyone interested on iron powder stator? Any ideas about the shape? I know this is a big investment only for experiments ... This is not a business of mine (I am not good on this). I only sent emails to Rofep with questions about this. I think in Sidney is a romanian community, anyone reading this forum (for translating the letters) ? Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

rotorhed Newbie Joined: 29/01/2007 Location: AustraliaPosts: 36 |

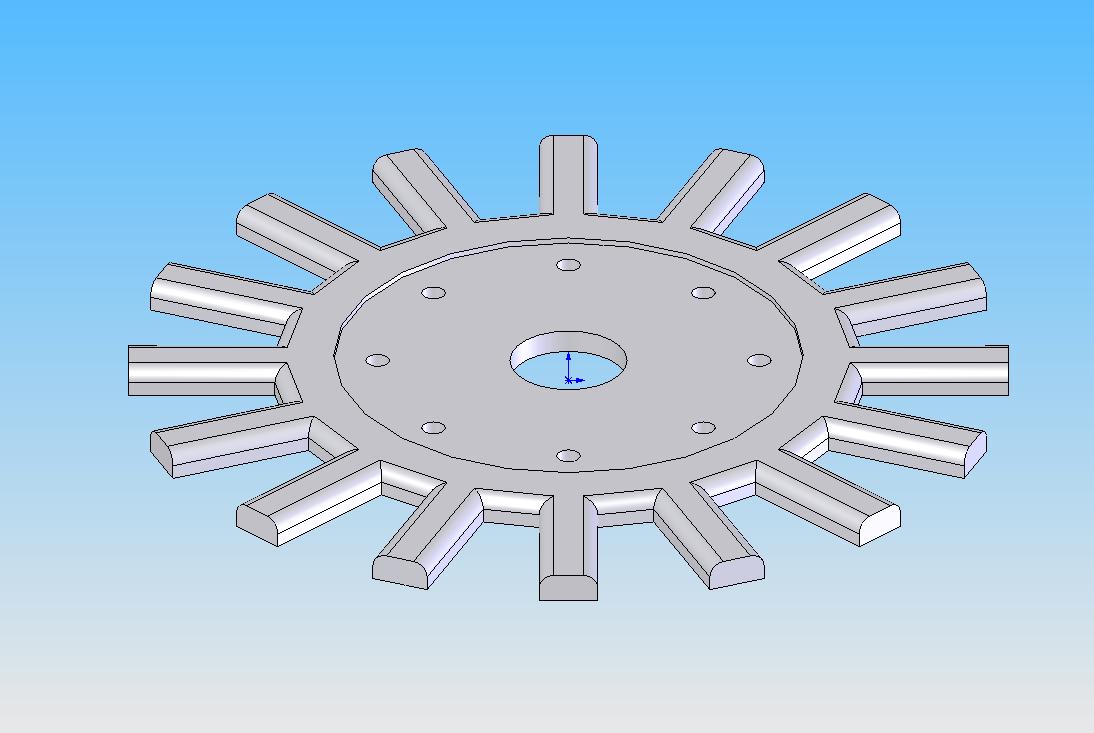

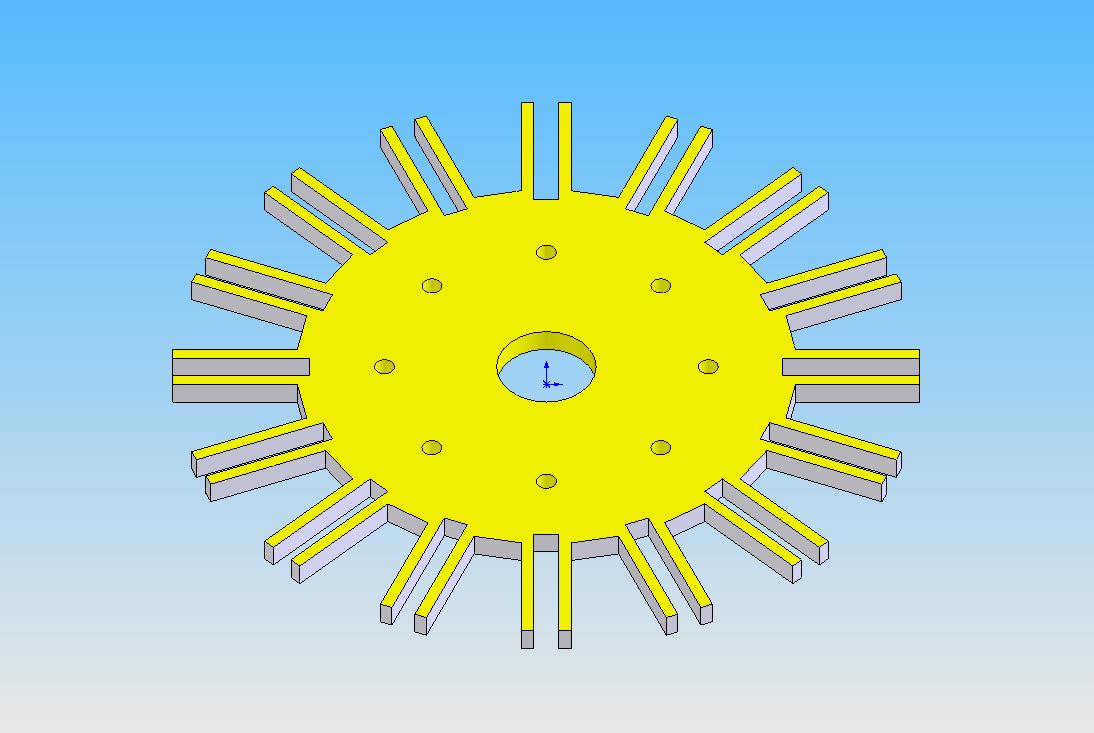

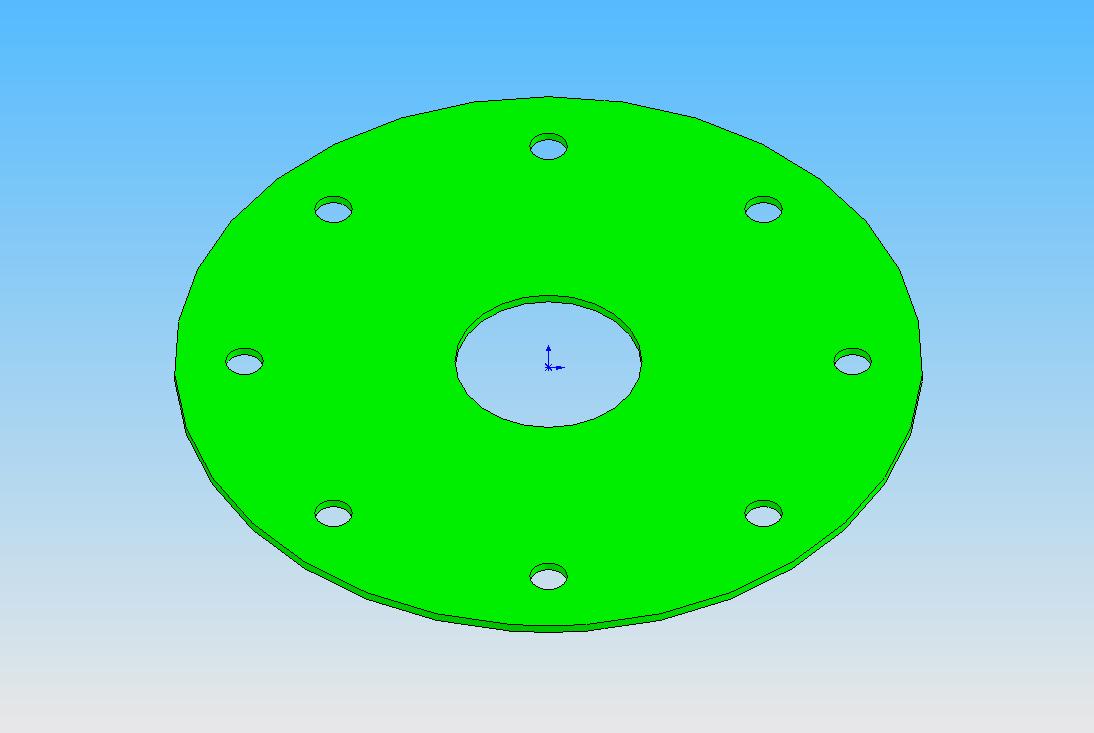

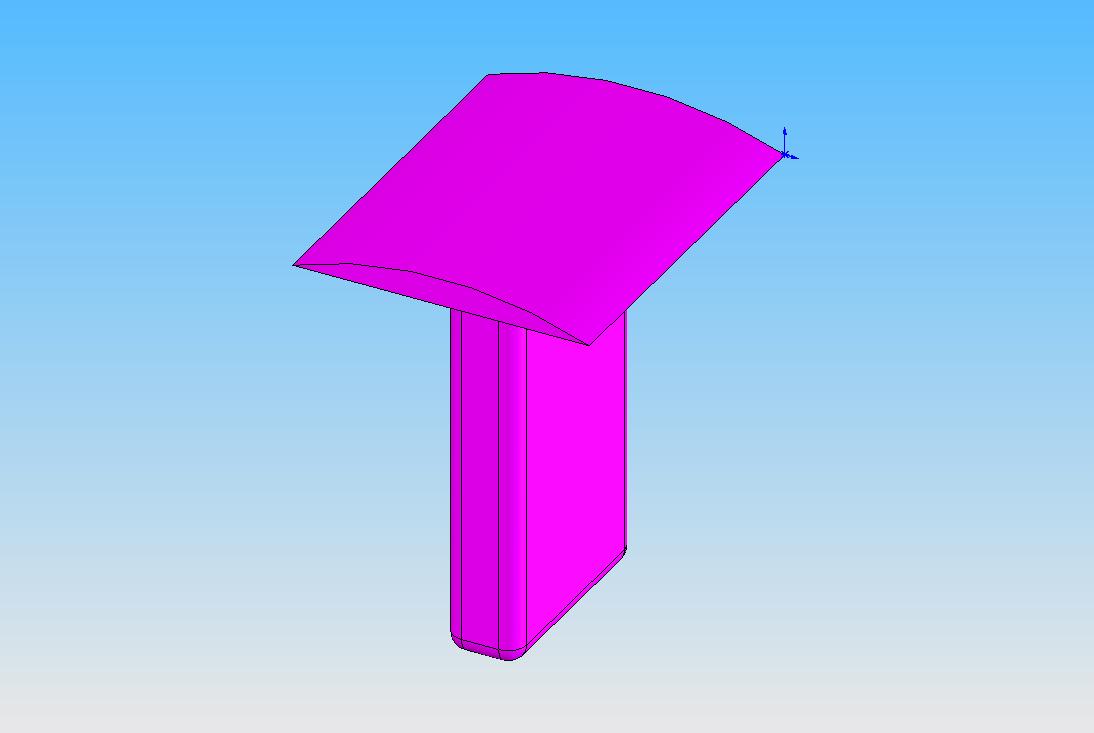

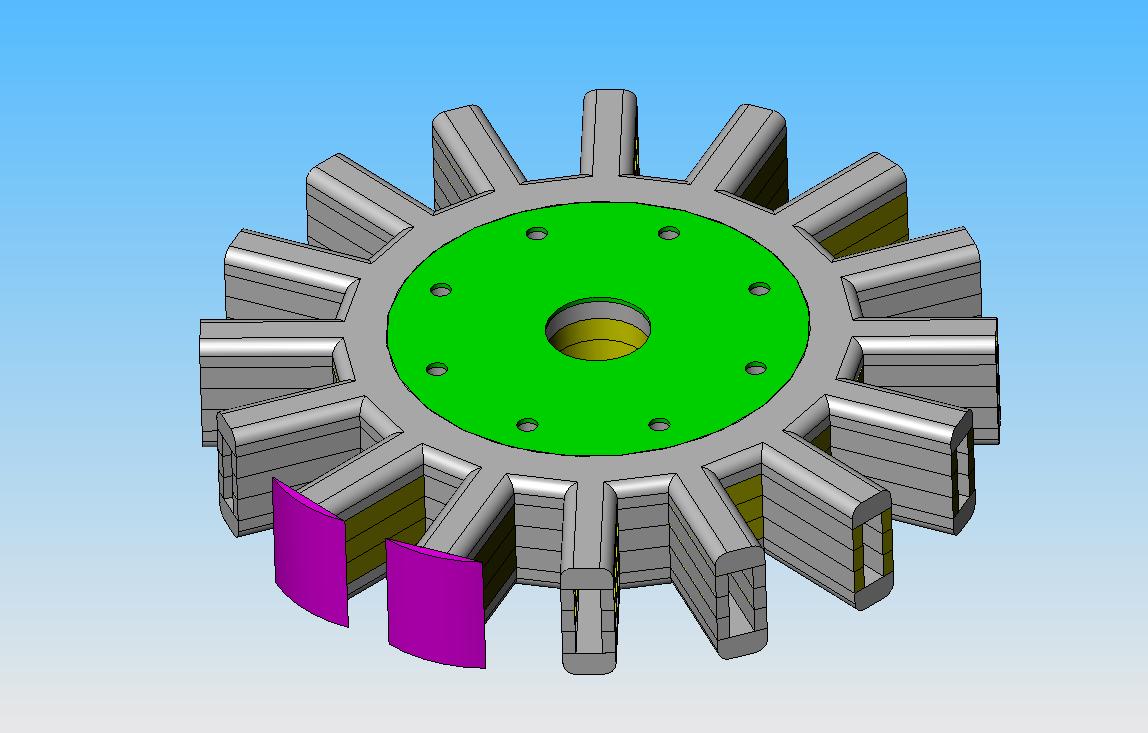

Hi guys I have finally been able to put thoughts on this idea into an image. The idea is to have pieces routed out in a material that I use here at work (PVC sheeting) it is light strong and easy to work with cost is a little on the high side but would be cheaper than using aluminum. For strength I have included aluminum plate disk (green). And the idea of using the powdered iron was an excellent idea except if you made the whole stator out of it the stator would be very fragile. So I propose a mushroom (purple) shaped piece of the iron powder. The parts would be possibly glued and bolted together. Anyway here are the pictures of the model I did in solidworks.

Anyway the other part of the idea is to have a metal drum spun up by some metal spinners in say aluminum or in gal. doing it this way is extremely cost effective they would probably work out at around the $20 mark maybe cheaper. Please everyone comment on the ideas as this is the best way to progress. (please note I have not included things like bearings and carriers as I'm not sure what would be the best solution as well as the main shaft) Cheers Christian Marge the Winds are here Ah McCaine............. |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Great design, also can be made from wood and sealed. We hope the copper is close enough. I think is time the others join us  . .Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi good to see you working on design rotorhead. I am very interested in use iron powder my main application is in the area of hydro at high pressure so always need to slow down FP to get eff. The concept I feel that would keep things simple would be to get building blocks like leggo made and build up stators by stacking together and gluing (with resin impregnated with powder ). at present i am brushing up on magnetic circuit theory to see if we can replace steel core. Iron powder does not carry fields as well as silicon steel we will need to enlarge pole piece and shortern no problem there at present instead of reconnectig i rewind to replace a 100SP FP u only need 6 turns per pole looks wrong but works like dream so no need for space between poles. Anyone out there into magnetic calculations etc its been 44 years since i was student and last time i needed to study this area ? Herb |

||||

| windstuffnow Newbie Joined: 30/06/2006 Location: United StatesPosts: 31 |

Here is one I put together a short time ago, just playing around with odd magnet to coil counts... http://www.fieldlines.com/story/2007/4/25/18557/4033 and http://www.fieldlines.com/story/2007/4/27/23308/0962 Also, some radial air core type alternators... http://www.fieldlines.com/story/2006/10/22/02031/103 and a small 4 pole here ... http://www.fieldlines.com/story/2006/10/16/24350/055 The air core isn't the most efficient design but their quite simple to construct. You can use welding wire or similar to wrap around the outer diameter to form a laminant type backing, this works quite well but takes a bit of wire depending on the diameter of the rotor. Using the wire also helps keep the eddy currents at bay. Any low grade wire works the best or toss a roll into a fire to aneal it... the lower the carbon the better. I've also made a few using PVC pipe, drilling the ends with holes to hold the wire while winding it around the OD . It would be easy enough to weld in an inner diameter ring on the radial type alternators to give you a rotating magnetic path oposite the magnets, no iron losses using an air core design. I've done a couple axials that way as well. Not as good as the dual magnet plate design but its far better than an air core. The brake drum alternators work well but it's difficult to find motor laminants that are the right size for the drum, unless of course you make them. Hopefully that will bring up some new thoughts... Have Fun! |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |