|

|

Forum Index : Windmills : Added details on rewire-ing the 36 pole

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Everyone. I've made some additions to the re-wire page... http://www.thebackshed.com/windmill/FPRewire.asp It now includes some diagrams for the new 36 pole stators, and mentions the 7 phase and staggered stator rewire. If you see anything wrong let me know. I need to develop and document the staggered stator, but time is in short supply at the moment. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Glenn, You may have to check the spelling manually in the above link. I found, plaqued, not plagued, and savious, not savonius. cheers, Gordon. become more energy aware |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Thanks Gordon, spelling was never my strong point at school. I'll fix those up tonight. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Glenn, The spelling checker is not going to find "miss matched", which is a problem, but I certainly would like to meet this miss. Cheers, dom Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| martinjsto Senior Member Joined: 09/10/2007 Location: AustraliaPosts: 149 |

wow, the rewiring possibilities with this motor is fantastic. more we do the more there is to learn. great work guys martin free power for all McAlinden WA |

||||

| feix62k Newbie Joined: 30/07/2008 Location: AustraliaPosts: 36 |

Hi can you run a standard early moter without mod the wiring, as I am following the directions to build first winmill,and they use a gear cog on there one but recomend welding a plate on shaft what gives, what other methods of blade mounts can you use on the f and p mill dont the days seem lank and long when nothing gos right and everthing gos wrong |

||||

| martinjsto Senior Member Joined: 09/10/2007 Location: AustraliaPosts: 149 |

hi feix62k the standard f&p motor will output over 500vac when spun in a lathe the output voltage increases, to a point, with speed, as wind gens make use of lower RPM we need to modify the wiring to take full advantage of limited RPM. Gearing dosnt work too well because of the cogging or inertia effect, their too hard to start turning unless its a gale everyday. we reduce the natural cogging of the f&p motor by either decogging the stator (rounding the ends of the stator coil laminates) or use the 7 phase rewire mod. there not too hard just take your time I make use of the f&p shaft using the spare spline to drive the blades( or in actual fact the wind drives the blades, driving the shaft and motor). there is a kit details available on this link from the homepage http://www.thebackshed.com/Windmil/assembly.asp good luck martin free power for all McAlinden WA |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

Hi gang, I have been trying to compile a list of F&P rotor and stator part numbers. Has anybody done this? I am looking for the part numbers for what is referred to as the 60 series. The drawing on the "which fp" page states that it is decogged. Is that factory decogged or modified as shown on the "decogging" page? I have recived a 42774p rotor from F&P, but can not figure out which stator to purchase. I an doing the 7 phase mismatch with the 36 pole rotor and the 42 coil stator. I live in Texas so there are no junk parts available, only new. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Barney, I am looking at two 60 series now and they have the following labels: a bar code SN: 390645 Wndr14 P/N: 426454-1: 1 12 SN 127313 Wndr(??) P/N 426454 Date 27 10 19?9 Time 17 36 I feel that P/N: number is the part number and if you ordered that then you'd get a 60 series even without knowing the washer models it suits. I see a 100 series with the number MDL: 425003 1 268 and six 80 series: MDL: 425623 1: 196 MDL: 425623 1: 235 MDL: 425623 1: 258 MDL: 425623 1: 9 2 MDL: 425623 1: 278 MDL: 425623 1: 119 Also the MDL number is the part number for the earlier 80 and 100 series. I think the last 3 digits after the : is the batch number. But order the number between the colons and you'll get the right one.

was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

Thanks Gill. I was under the impression that the 426454 was a 36 coil as stated here...http://www.thebackshed.com/Windmill/FORUM1/forum_post s.asp?TID=396&PN=2 The What F&P is it page.. http://www.thebackshed.com/windmill/WhatFP.asp states that the 60 series is 42 pole. You are looking at the stator so I believe you have the right info so one of the other pages must be wrong, or am I wrong? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Barney, Yes that post by tinbender cannot be correct. I can assure you stator 426454 is 42pole and is the 60 Series with 6mm wire. I see he advised a part number change from 420775 to 426454 and this was for the 36 pole stator. I feel this is incorrect and perhaps the parts people is USA are not fully aware of the differences. I note the parts list he posted is also incorrect in that the shaft (8) and rotor nut suits the old 42 pole models and not the modern 36 pole stator. The 36 pole shaft uses a bolt and not a nut. Count the poles of the stator, there's 42. The Rotor number is also for the 42 pole motor. You've been given a bum steer I'm afraid. I'd stick with 420775P for the 36 pole stator and 420774P for the matching rotor. All Rotor & Stator part numbers: Very Old Rotor - individual metal magnets (100Series)_ 425011 Old Rotor - for 100, 80, & 60 Series _ 425620 New Rotor - for 36 Pole stator _ 420774P Stator 42 Pole - 100Series _ 425003 Stator 42 Pole - 80Series _ 425623 Stator 42 Pole - 60Series _ 426454 Stator 36 Pole - New _ 420775P There were some variations with rotors in the type of material used, though I have not noticed any variation in the part numbers on them. If anyone has a part with a variation to the numbers above, please post it with a description. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

Gill, To confuse things further the rotor I received from F&P reads "fisher&Paykel whirlpool part no. 8565177 >PP-GF30<". It has 16 blocks. Sears sent me the same one but full of cracks that looked like manufacturing flaws so I sent it back. A parts search on the Sears site says that 8565177 replaces 280146. I enjoy a good puzzle but it does slow down human progress. This is the sort of corporate logic that brings evolution to a crawl. I really appreciate the input. It is like a torch in the dark and I only had to look 10,000 miles away to find it. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Barney, You are right, confusing it is. Typical of mail order businesses they put their own catalogue number on listings that often has no relevance to the manufacturers number. Mail order electronic components are a prime example. Sears are known to me as a very large American mail order business. Could it be they use their own catalogue numbering system over and above the manufacturers? The rotor with the 16 blocks will have 3 x chevron shaped magnetic zones per block making a total of 48 magnets which is correct for a 3 phase stator of 36 poles. To answer an earlier question, the 60Series stator does not come with rounded poles. Only the new 36 pole stator comes factory done and this compliments the matching decogged rotor like yours.  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

The die is cast. I have ordered part no. 426454p in hopes that I receive a 42 pole. If it turns out to be 36 I will be digging for posts on new stator/rotor combination. From what I've read the results have not been great. I spoke with a nice guy in New Zealand with F&P who recommends the South Island for adventure. I sure do love the internet. If this thing blows up, it will still be the most fun I've had in years. |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

Just received stator 426454p. Work of art. 42 poles. Do you know the part number for the proper shaft fot the 36 pole rotor? I assume that it is more important that the rotor matches the shaft...so I need the rotor for the 36 pole...right? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

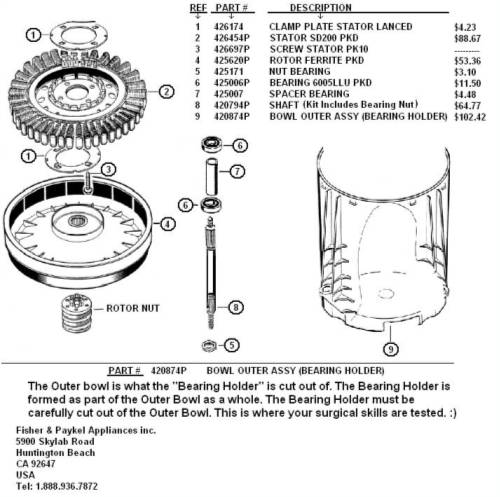

Great stuff Barney, now you have the electric bits, lets get the mechanical supporting parts sorted. With ref to Tinbenders parts pic:

I suggest the following: Shaft 8 plates 1 x2 nut 5 bearings 6 x2 spacer 7 rotor nut n/a (suit the old rotor) Further comment, Some of these parts (bearings & spacer) depends on just how you intend mounting the shaft to the mill. I like to use a hacked out piece if the Bowl 9 but don't recommend this to you for cost reasons. Glenn uses a different bearing arrangement and this supports the shaft closer to the prop which is a structurally superior design. I have never used this design but feel it better suits your lack of F&P resources. Glenn's construction details are on this site. I think you could also use the new shaft as it's rotor spline and all other aspects are the same EXCEPT for the bolt and mating shaft hole for securing the rotor. The old method used the threaded shaft end and Rotor nut as shown in the parts pic. So either new or old shaft with their corresponding bolt or nut will do the job. Your choice really. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

Thanks Gill. et all. The 7p2p seems to suite my needs, but I am looking for any documentation on the various wiring options. I will be starting out with a 2 meter 3 blade setup, but will be playing with blades as I go along. No tower yet so the winds I'm using for testing are low and chaotic. I live near the Gulf coast so it is feast or famine. We are expecting winds of 140mph in a few days. Advanved furling perhaps? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Good one Barney, I don't know that you'll find much in the way of added info other than what's on this site and it's forum. Not a lot of data or comment from experience on the 7 phase setup really. EcoInnovation has power curves and such for various series and configurations but all 3 phase and none on 7phase. What's advanced furling? I have visions of the tower lowering itself in a hole in the ground much like lowering a cars radio aerial when parking in the city. I need advanced furling too come the cyclone season.  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Barney Newbie Joined: 21/08/2008 Location: Posts: 7 |

I was picturing a boom about 40 miles long to swing it inland. I'm also picturing a wiring harness with 84 connectors. One of these is more conceivable than the other. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |