|

|

Forum Index : Windmills : AWP alive and well again.

| Author | Message | ||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

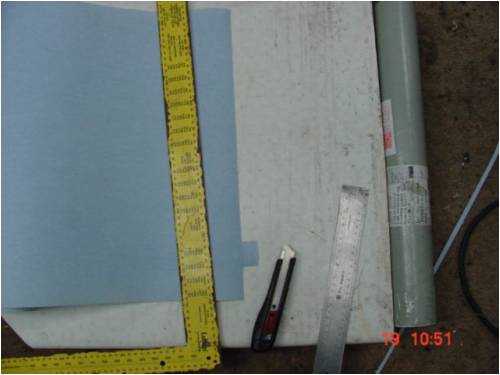

Well after finally getting a chance to start work on the AWP again, it is healed. First we have to cut some transformer paper to fill the slots to protect the wire enamel from the steel stator. Here is the paper that Zubbly sent me.

We cut it up and place it in the slots like so:

Now we find some likely source of wire to fit our requirements. In this case, the center rotor core from an alternator seems to be .8mm thick, so thats what we'll use. Here are two spools from alternators. One half used already (on this project).

We need to straighten it or it won't fill properly, and this stator is a killer, thin slots, very thin gaps. You need the wire straight or it will not load into this stator. So we run it into a few bearings like this:

The wire goes from the spool through a few bearings and off to the winder (which is horribly basic, but works well)

Sadly I forgot to get a pic of the coil itself. I needed 7 of them. 5 single coils, and 1 dual series coil. ie 2 coils wound 1 after another without cutting the wire between coils. We then place them into the stator and it looks like this

Then it is a simple matter to put it back together and test it. So here it is temporarily back together to test. The Ohm test put the phases at 25.1 ohms they were equal, so should be good.

and here are the test results. 108vac. at only 18.8hz for 30 poles that is about 75 rpm. or 240vac. @ 166 rpm. Volts on the left, hz on the right.

Now it just needs some enamel and it can go fly again. In this case, it will probably be stripped and rewound again soon to do a proper job perhaps. ...........oztules Village idiot...or... just another hack out of his depth |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Nice Work Dr.Oz

It would be cool sometime to see Jamies system.Like the water heating section. |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Glad you got it running again. Very quickly too. Even though it's a 'temporary' repair I'd definitely try to varnish/enamel it as well as possible. I don't know about you but in my case, many temporary fixes last a long time. Some over a decade.

I wouldn't reuse wire myself but you and I are in very different situations. Reading your stories made me realize what a lucky bastard I am; if I need a bearing, piece of enameled wire, rubber seal rings for canning jars or whatever, I can jump on the bike and be back in 1.5 hours with what I need (as long as I bring money with me). Believe it or not but sometimes when I'm in the hardware store looking for an extremely rare whatchamacallit I wonder how you'd solve the problem on your island without hardware stores :) Excellent job. The only thing that had all the neckhairs on my neck stand up straight was the can with WD40. Hopefully you just use it as a paperweight. I wonder what the next thing is that will fail on the AWP.

PS: good to see the legacy of Zubbly living on in the shape of transformer paper in the AWP. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Vawtman, There is nothing to see. It is a standard domestic hot water service (about 40 US gallon, plumbed the same as if it were in your own house on the grid. He has a 24kwh battery, and 5-8kw pure sinewave inverter that runs the place as if it were connected to the grid. It runs the hot water unit (probably 3kw), the self heating washing machine, dishwasher, heated spa, welders etc. and all the other stuff you would expect in a modern house in down town Manhattan. You would not know it wasn't on the grid.... Because of his position on top of the mountain ridge, the mill runs nearly all the time, even when it is still down here on the flats, it will still be doing 7-900 watts up there. He has 1kw solar array, which is pretty worthless here in winter, but still, almost every time I go there, the mill is dumping. In summer the solar contributes heaps, and so the mill dumps pretty much all the time then. The boys on otherpower would have a fit. When a newbie comes on and wants to turn their house off the grid with a little windmill and a few solar cells, they cop a beating, but on his site it would allow them to do it. There is no attempt to skimp on power, or economise. There is too much most of the time. So the AWP works very hard indeed. So if you have grid electric hot water, then you have seen his setup. So sadly no mystery stuff there. The electrical system is in those links Dinges gave out. Hows the big alt coming along? ......oztules Village idiot...or... just another hack out of his depth |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

He he he, The WD40 was on the table because I was playing with my little Stirling Engine, and I use it as a very low viscosity lubricant on the power piston and displacer.

The stator....yes it has to have a bath in enamel before it goes up. Thats why I said "So here it is temporarily back together to test. " because it has to be dismantled to enamel. The plastic ties will be cut off after the enamel has dried sufficiently before a bit of a stint in an oven of some kind. I solve the problem of not having it by building it, or substituting it, reworking the problem or running away and sulking. So far so good. I like the challenge. I have as yet not failed my fellow islanders with being able to fix everything they have thrown at me so far. I did think that the dead computer LCD screen the other day would probably be my first failure, but as luck would have it, the problem was in the built-in switching power supply. (half dead electro-cap) So it's owner happily got it back the next day for free as usual. Otherwise .... straight to the tip. "PS: good to see the legacy of Zubbly living on in the shape of transformer paper in the AWP."........ might import the next batch from ... lets see, Canada last time... so...well the Netherlands looks good..

I think we have strengthened and rebuilt the entire machine now, hopefully when we enamel it, I may never have to rewind it. I might get Jamie to buy the wire now just in case. We have 1. rebuilt the tail 2. reworked the furling brackets 3. rebuilt the front drum and strengthened it 4. built 8mm plate steel blade holder disk 5. rebuilt yaw head completely (now bearings) 6. ditched the slip rings 7. partial rewire of stator 8. strengthened and replaced three blade studs 9. Fixed blades from poor manufacture (full of holes) 10 fixed the electronics for freq switching, dumping, high-speed o/loading, ssr control, bridge rectifiers I don't think there are any other parts to fix or strengthen now you mention it. Still want to replace the diode blocks for stud-mounts. I don't love using s/hand wire, but if your careful you can get away with it... hopefully. If it is ok when you wind, the enameling should hold it from then on. ...........oztules Village idiot...or... just another hack out of his depth |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

These are the kind of stories I enjoy the most! Good work and an another excellent post! You are the neighbor everyone would like to have.

"2 coils wound 1 after another without cutting the wire between coils" 30 magnets and 90 coils, IIRC? 30 coils per phase. Where does the 2 coils come into play? They must be on the same phase? philb |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

If you look at this:

and this:

you may notice that the outer layer is missing two coils, and the inner layers all need 1. Remember each coils occupies only 3 segments. it then has 3 empty segments then another coil so they span wider than it first appears. So on the outer layer it is the only place I could wind two coils (as part of the same half phase) that ran contiguously. The other 5 layers needed only 1 each so I was having to do 10 splices for 5 coils and only 2 splices for 2 coils in the outer one. For this I just wound 1 coil, took it off and plastic tied it to the winder shaft and wound the second coil without cutting the wire. Saved a pair of splices thats all. The other odd thing about this stator is that all coils are wound in the same direction, but miss every second coil that you would have expected to find. It does make it easier to wind without stuff ups, and achieves the same thing. ..........oztules Village idiot...or... just another hack out of his depth |

||||

CraziestOzzy Senior Member Joined: 11/07/2008 Location: AustraliaPosts: 152 |

*WOW* I like your idea of the high tech equipment you use for straightening your copper wire. I was thinking of someway to straighten my recycled wire and seeing your masterpiece, I most definitely will give it a go. http://cr4.globalspec.com/member?u=25757 http://www.instructables.com/member/OzzyRoo/ |

||||

| Janne Senior Member Joined: 20/06/2008 Location: FinlandPosts: 121 |

Hello all, the new guy posting here. First of all, congrats, the generator looks super. I was just wondering, where has the stator(and the rotor too?) been plundered? I haven't ever seen a motor like that here in Finland. If at first you don't succeed, try again. My projects |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

Its a commercialy made machine he has rebuilt. AWP website One question Oztules.. What does the "Grid" consist of on the island. Local diesel gen station or what? |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Hi Robb, The "grid" over here consists of a new ( well actually second hand from USA) 1MW diesel alternator plus 2 backup 500,000watt gennies. Power distribution across the island is 11000 volts, and nearly everyone has their own 24kw transformers (100A 240v). I got hold of the old genny they replaced here:

It weighs upwards of 2.5 tons. Had to use my trac (955l cat) to unload it, the Fergie tractor had no hope. It is supplemented by two wind turbines (which I look after the electronics for for a friend) but only around the 100kw from these. Next I am down there I will get some pics. ..........oztules Village idiot...or... just another hack out of his depth |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

I saw that big beast via the links in your profile. Wow  . .

All the same I'd hate to fuel an engine for that

Yah love a look at the big ones. Cool. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

BTW, my method of straightening copper wire is to anchor one end then unroll the entire roll (across the park if needs be!  ) then with vice grips or some such pull on the end to stretch it until I feel it 'give'. ) then with vice grips or some such pull on the end to stretch it until I feel it 'give'. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Yes KiwiJohn, I do the same thing as a preliminary if the coil is unruly. From the shed I can go maybe 2km westerly before I hit a fence.... haven't had to use that far yet. I then wind it onto a large diameter thing (like an 18" 2b pulley or two). This gets it manageable so I can use the bearings on the desk to finish it off straight onto the winding former. The bearings also strip off flaky and not so flaky varnish, (sadly not all and I still get some cuts from the varnish left on.) It does not seem to bother the enamel though... which is a good thing. .........oztules Village idiot...or... just another hack out of his depth |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |