|

|

Forum Index : Windmills : Distance of tower from batteries?

| Author | Message | ||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Hi all, new member here. I have been threatening to build a F&P wind generator for several years and even went as far as making the blades a few years ago. Well, the time has come and now I am finding how much I don't know. My setup is a 48v stand alone 1.9Kw PV system with PL60 controller and 3Kw inverter, 24 Lucent Synergy sealed lead acid batteries of 650a/hr. This system has been working great for the last 4 years but I have recently increased the load and find it struggling to keep up now. The gen set has done around 100 hrs in the past few months.

I now realise that a F&P based gen is not going to be adequate but since I already have most of the bits, it would be a good way of testing the location of the tower and to get an idea of how much wind we have available. The guyed tower consists of an 8m octagonal pole as used for street lights with a 6.5m length of 3" water pipe ontop of that and then around 3m of 2.5" water pipe at the top giving a total of 17.5m.

This is the base of the tower after rewelding it back together as it was found in two halves.

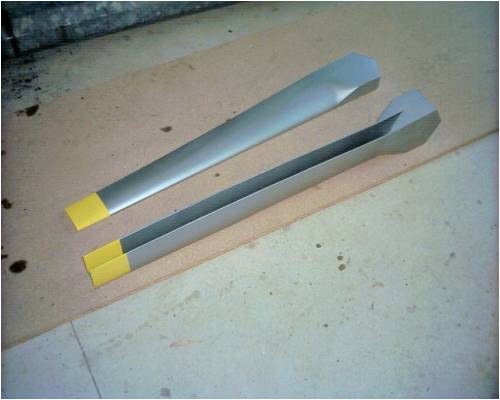

These blades are carved from laminations of 18mm plywood as per Hugh's instructions although I measured them today at only 1150mm long so the dia is 2.3m. They were then given kevlar leading edgesand carbon on the MAC and coated with woven cloth and epoxy resin. The finish is 2 pack paint.

This is were I am up to with the head of the machine. It's based on a 60 series F&P which is wired for 2 pole star or delta. I wish I hadn't rewired it now as I think I am going to have trouble getting the voltage I need.

I still have to sort out the furling system. I had an idea to make a spline for the prop drive. I'll drill a series of 20 holes, 2.5mm dia on a 19.5mm PCD into a piece of 50mm bar. Then machine the centre out to 19.5mm which should leave me with a spline which should provide enough drive for the F&P system. Then weld the 50mm bar to the prop back plate and away I go. The dimensions might need tweaking but I'll double check that before I start machining.

The tower will stand somewhere here. The tall tree's will be lopped. My problem is that the tower will be approx 82m from the batteries plus the height of the tower so say 100m. That seems a long way to run a potentially high curremt. My questions is, am I better off running the ac down tho the batteries and rectifying it there or should the rectifiers be up the top of the tower? I want to be able to switch from star to delta from the ground so I am guessing a three phase contactor will do the trick on top of the pole but I am unsure where would be best for the rectifiers. Also, what is the most common dump load you fella's use. I am thinking just a bank of spot lights but thats not very imaginative. There must be more useful alternatives. Well that enough babbling on for my first posting, and thanks in advance for your help.

Regards Moose. Regards Moose |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi moose, I think the 2.5" top section is too weak. The PL60 is no MPPT for the solar system. You are losing energy from the solar. I would upgrade the solar to a MPPT and use the PL60 to control the windmill diversion load, with a separate rectifier, so the battery is not cycled. You have a 48V system, so current will not be excessive. 10mm conductors are probably OK. I hope this helps. Gordon. become more energy aware |

||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Thanks Gordon, The acronym MPPT is new to me. Could you please enlighten me. When you say a seperate rectifier, do you mean nounted at the batteries? Maybe a schematic would help. Thanks again Gordon. Regards Moose Regards Moose |

||||

AMUN-RA Senior Member Joined: 10/03/2007 Location: AustraliaPosts: 144 |

moose just google maximum power point tracking solar charge controller or mppt have a read I have an outback mx 60 and it works fine Mick Every day the sun shines & gravity sucks= free energy. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Moose,, I have similar cable runs of around 100 Mtrs. I use 16mm and 10 mm overhead covered electric cable from the line depot scrap bin. It's stiff,but crimped connections and waterproffed joints make it good,. your tower should be fine with say,3 sets of 4mm steel guys ,are you going to have it so it can be lowered by a winch or so?. Nice area you are in ,I'm around west of the gold coast in the hinterland . Bruce Bushboy |

||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Thanks Mick, I've educated myself on mppt's now. Learn something new every day. Bruce, nice score with the cable. I can only imagine that 100m of 10mm three core is going to be many hundreds of dollars. Maybe I can try your trick and get friendly with the local ergon fellas. The mast will be raise and lowered by turfor and gin pole. I was planning on two sets of guys at 6mm but you could talk me into three sets at 4mm if you try hard enough. Ultimately I want to replace the F&P with a 2Kw unit if all goes well. Regards Moose Regards Moose |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

in that case ,,do the upgrade now in the wire dept and use 6-8mm wire and three sets. The cable ,,,,go see your local line depot,,tell them what u are doing ,invite them around ,Etc and offer a couple cartons of 'soft" drink for their xmas break-up day.. Bruce Bushboy |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi moose, It is a tall order to expect that a 2kW mill would survive lifting from the horizontal, or any decent wind on a 2.5" water pipe for the top section. Gordon. become more energy aware |

||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Yes I think you are right Gordon. I was going to use the 2 1/2" for the F&P mainly because it mates up to the smaller head a bit better and it's only a 2.3m prop, but the 3" will be the last section for the 2 Kw unit I think. Also, because of the slope of the site, the lift will begin from about 15-20deg above horizontal hopefully eliminating the worst of the load. I scored the 3" pipe today from a mate who deals in scrap. It's an unused 6.5m piece of the old fashioned ultra heavy wall pipe that you just can't seem to get anymore. Only cost me $50.00 too!

Regards Moose. Regards Moose |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi moose, here is a photo of tower that I posted a while ago for a 2kW mill. this is 19.5m with 3x4 guys, with gin pole setup. This is 150mm gal steel. You may get away with 100mm for the lower height. Gordon. become more energy aware |

||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Thanks for the info Gordon. The street light pole I am using for the first 8m is tapered but it starts at 200mm and tapers down to 125mm with a 75mmOD heavy Tube on the end which will be a snug fit inside the 3" pipe. Any idea of a good source for wire rope? Regards Chris Regards Moose |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

The wind loading of a 2kW mill is far greater than that presented by the original street light that would have been attached to the 75mm section on the top of your pole. The mill nacelle will be at least 1.8m above the guy point for a 2kW mill. Good luck with a 75mm pipe! Gordon. become more energy aware |

||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Keep in mind the original street lamp was free standing but now it will be guyed. Chris Regards Moose |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

The top of the pole is the problem, above the guys. Gordon. become more energy aware |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

well,, I guess Phill's lesson should tell you a bit about forces ,Chris. A 2Kw mill is not a toy,and unless you really construct the tower very strong ,then you are in for big time trouble. Remember ,that street light tower only had to hold a 10 Kilogramme light fitting ,and, more important, they are constructed so as to fold quickly when a car or motorcycle hits them,for safety. My tower is 4x4 x 3/8 structual tower steel (off a tv tower) with 1 inch dia bolts clamping the steel back to back..the guys are 3/8 inch tensile steel hard drawn 7 starnd with 1/2 inch thread turnbuckles. and my mill is only around 600 watts,she still screams in a big blow .so what would a 2 Kw job do? play it safe ,old mate .. Bruce Bushboy |

||||

| Moose Newbie Joined: 27/11/2008 Location: AustraliaPosts: 7 |

Phil's experience should serve to demonstrate the one thing I would never contemplate is using steel pickets for guy stays. From my experience, and I use them a lot, they are grossly inadequate in that application. The fact that the picket pulled out without even bending clearly demonstrates it's lack of holding capacity. No body uses star pickets as strainer posts! Regards Moose |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Star pickets are fine for anchor points IMO, as long as they are encased in a big lump of concrete and go deep into the ground. The ones I had were encased down to about 1.5m below ground and in about 300mm diameter concrete. Once I no longer used the mast one anchor needed to go as it was in the way of a new shed. The bobcat operator had real difficulties in first digging it out and then loading the concrete lump onto his truck. The star picket that had the broken guy rope is still there - too hard to remove it - and I bet it could still guy a substantial tower. Klaus |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |