|

|

Forum Index : Windmills : Closer look at push bike hub motor

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

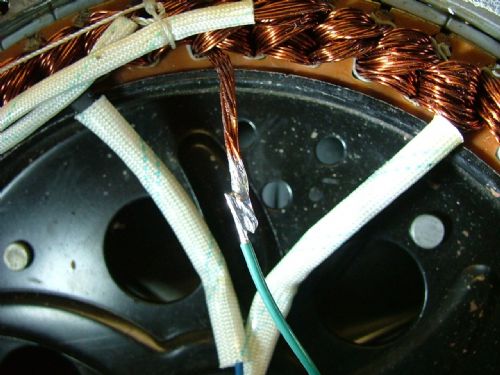

Just for interests sake. I have a 300 watt hub motor from China. These are very well made, though there are a couple of area's that need attention before they could be used on a windmill. The first concern is the shaft. Its 15mm at its widest point, with a 7mm hole down the middle for the wires to pass through. On a push bike where the motor is supported at both ends of the shaft, this would be sufficient. But for a windmill where its only held at one end, it would break easily of the turbine was out of balance or there was a sudden wind direction change. It would be easy enough to strengthen, with a new shaft or a sleeve and bigger bearing. The other problem I've noticed is the lead out wires. The coils are wound multi strand, 8 of 0.6mm copper enameled wire strands bundled together to give a diameter of about 2.5mm, but the lead out wires measure only 1.2mm diameter copper, thats a big step down in cross section, and a big reduction in the current handling capability of this thing either as a motor or alternator. The easy fix is to mount the rectifiers inside the alternator, connect the -ve to the shaft and feed a single 4 or 5mm copper wire through the 7mm hole as the +ve. There is no noticeable cogging, and its easy to turn my hand. Here's a few photos.

I'm itching to get this motor rigged up for testing, I think they have potential. Could also be a candidate for caps. Hows this for a different kind of rainbow.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

CraziestOzzy Senior Member Joined: 11/07/2008 Location: AustraliaPosts: 152 |

Yeah, hubs are a good thing if you can get your hands on one. I figure they were generally too small, but yours is of a decent size and looks like it has neos for mags? http://cr4.globalspec.com/member?u=25757 http://www.instructables.com/member/OzzyRoo/ |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Glenn, out of interest, How many magnets and slots? Gordon. become more energy aware |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Gordon 46 magnets, 52 stator poles, and the stator is about 200mm diameter. Spin by hand gives approx 10 to 15 volts at approx 100rpm. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Wow! I think this is a recovery from a backup! What happened? Glenn, what photo camera you use? Nice rainbow! Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Vasi Yes mate this is a recovery from backup. The servers have been down for 2 days!!!! Will post a message and work out whats been lost when I wake up and have my coffee.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Repost of missing posts sPuDd wrote..... Glenn, what method are they using to drive this 3-phase unit? Seems like it would be a challenge to run it as a motor. I assume the 8 in hand method is used due to the small turn around room at the slot ends and the low DC voltage with high current. Did you try it on a bike to see what the get up and go is like? sPuDd.. Now I did reply to this, but the forum doesn't email my own replies to myself, so its gone. Quick answers - 3 phase controller, like the F&P. Mass production gets price down. No. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |