|

|

Forum Index : Windmills : just pickup this new motor

| Author | Message | ||||

| divemaster1963 Regular Member Joined: 28/01/2009 Location: United StatesPosts: 46 |

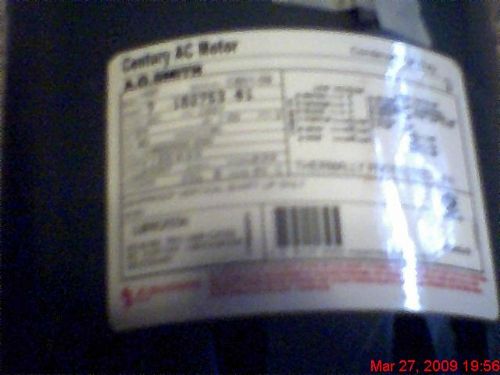

Hey I just pickup this new motor today. Its a A.O. Smith Condenser fan motor 3/4 Hp 460/200-230 Volt 1140 Rpm Polyphase Cat no: H567 Any sugestions on how to convert?

sorry about the pictures cheap camera.  |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

I would rate similar to the photos. The shaft is pretty puny. If you desperately feel you need to do a motor conversion, dinges may add some. Gordon. become more energy aware |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Long time exposure ... because is at bulb light... try to not shake the camera when you take pictures at room light. Here are three reasons when you have blury photos because of you: first, long time exposure because the light is poor and you can't keep still the camera for long time, second, when you press the button and shake the camera at the same moment, in daylight conditions, and third, you are too close to the subject and you are not in macro mode - my camera have a 20 cm minimum distance between the subject and photo lens in normal mode. If your camera don't have a macro mode, try to respect the minimum distance and increase the photo resolution - say equal or better than 1024 x 768 ... Then, you can crop the desired part of the photo. You can make better photos at day light. Regards, Vasi Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

I tend to agree with Gordon on this.Those condenser motors often times have cheap sleeve type bearings and looks like that is what this motor has. They don't want to make them too tough otherwise we would have more maytag repairmen outthere

There are better fish to fry.Keep divin |

||||

| divemaster1963 Regular Member Joined: 28/01/2009 Location: United StatesPosts: 46 |

yea the camera i have is a cheap 9.95 walmart one. I' try to get better photos. We have been in very low lighting because of sever storms past 2 days. here is a few more. the shaft is 7/8 ths just inside housing. was thinking of beefing up shaft on out side with sleave up to the tapper at the bearing.

|

||||

| divemaster1963 Regular Member Joined: 28/01/2009 Location: United StatesPosts: 46 |

The bearings seal to be pretty good. they are the same sealed bearings i have on commercial mower pullys. |

||||

| divemaster1963 Regular Member Joined: 28/01/2009 Location: United StatesPosts: 46 |

I was thinking of posibly mounting this further back on the mill, use a sleave over shaft supported with a block pillar bearing thats low friction high speed. any sugestions on nuber and size of magnets i should use. hey I got this motor for only 20.oo us. brand new in box. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |