|

|

Forum Index : Windmills : Furling vs. Changing Pitch

| Author | Message | ||||

| Pukwudji Newbie Joined: 10/07/2009 Location: United StatesPosts: 20 |

Someone mentioned something in a previous posting that made me think. A couple of years ago when I was first looking at windmills I had seen some information on the internet regarding altering the pitch of the blades as speed increases. I actually found more information about this than furling the head. Now I can't find any information on it. I can't remember the details now that I'm ready to build one, of course, but from what I can remember it didn't seem much more complicated than furling. Actually, what I recall it seemed to appear pretty simnple. Does anyone know of any links of methods for automatically altering blade pitch as speed increases? Thanks, -Brian V Hillsboro, OR (USA) KF7DUZ |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

Pukwudji; Its called feather-ing. I built some blades some years ago and designed a system to feather the pitch. I started work building my house shortly after, so never got it mounted on a pole to work out the bugs. I'm going to look for the parts and pieces and see how much I still have. I'll post some pic's. and a few details shortly. Goggle must have something on this? Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

There is a company called Jacobs Wind Electric http://www.windturbine.net/ These were one of the original wind-turbine manufacturers in the United States. They bit the dust when the federal government backed rural electrification. At any rate, they used counter weights working near the hub. Each weight spun outward (centrifugal force) and twisted a little tapered gear that feathered the blades (3 each). You might look into the type of an arrangement to feather your own. I've also seen this done without gears applying the angular momentum of the weights against a flexible blade. Hope this helps. Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Janne Senior Member Joined: 20/06/2008 Location: FinlandPosts: 121 |

Put it simple; all you need for a centrifugal blade governor is: 1. mount all blades on bearings so that their pitch can be altered. 2. connectec the blades shafts together, so that each blade pitches the same amount. 3. mount flyweights at the blade shafts. Variable pitch album VP pitch image 1 VP pitch image 2 VP pitch image 3 edit. fixed typos If at first you don't succeed, try again. My projects |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

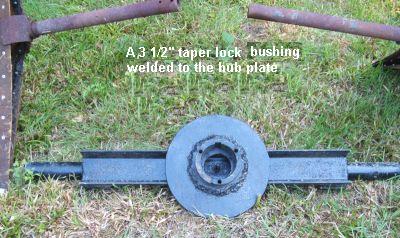

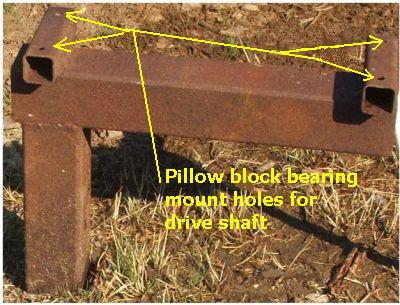

Pukwudji Below is the Pic's. of a long abandoned project I had built it to allow the pitch to feather in high wind but never got to test any part of it. A fluid shock absorber should be added to this to dampen the effect of gusting wind and flutter. This mill was built to drive an auto air conditioner compressor in the winter to heat water as a supplement to home heating, I figgered the Heat equalivent of 3 watts to 1 watt electrical would make the mill much more efficient than it would ever be as a generator.

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| montyLalor Newbie Joined: 17/12/2008 Location: AustraliaPosts: 21 |

My personal opinion favours feather-ing over furling, but as I haven't built a turbine yet, my preference comes from a purely aesthetic view-point. I just can't bring myself to build a tail that swings up and 'twisted' as it comes around. I believe it just looks unsightly, and besides, I want to have a tail with a vain-section below its arm-line, again because of how I believe it'll look. I don't doubt furling's effectiveness or efficiency, I just question how silly it looks in practice. Is this what you'd call 'engineering vanity'? Luke "So are you doin' this project to make us money or cost us money?" she asks again... |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

The method of load shedding usually only occurs in winds above 10m/s. You are worried about what the windmill looks like in these conditions? Gordon. become more energy aware |

||||

| montyLalor Newbie Joined: 17/12/2008 Location: AustraliaPosts: 21 |

Vain, I know, but yeah. I guess I'm just smitten by photos and stories of how robust the Jacob's turbines were way back when. If someone could build a turbine that survived for over 2 decades in the Antarctic (moreover to the point where the main reason it was decommissioned was because the snow-line had risen 60-odd feet to the point of it being too close to the blades), then why try and re-invent that wheel? I love drawing inspiration from old school thinking. "So are you doin' this project to make us money or cost us money?" she asks again... |

||||

| Janne Senior Member Joined: 20/06/2008 Location: FinlandPosts: 121 |

Hi montyLator, I think "re-inventing the wheel" is happening, bacause of the ultimate simplicity of the furling tail. With only one moving part ( the tail hinge ) you really can't get it any more simple than that. Of course, fine tuning the mechanism might be a bit more complicated, than with a variable pitch control. And also, furling tail won't limit speed if you lose the load, variable pitch will limit speed even if all the load is lost. If at first you don't succeed, try again. My projects |

||||

| montyLalor Newbie Joined: 17/12/2008 Location: AustraliaPosts: 21 |

Boom! "So are you doin' this project to make us money or cost us money?" she asks again... |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |