|

|

Forum Index : Windmills : Producing F&P

| Page 1 of 2 |

|||||

| Author | Message | ||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hello Guys, How about producing F&P under license? Trev, what do you think? Is possible? Guys, you are a team there in Australia, with many skills. What if ... Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

rotorhed Newbie Joined: 29/01/2007 Location: AustraliaPosts: 36 |

Hi Vasi I have also been thinking about this for a little while but as I have had very little experience with generators I have run into a few problems with the idea. If anyone would like to discuss the idea of maybe designing and manufacturing a device similar to the F&P post some comments I have a few ideas about it that would make it relatively inexpensive to build. Cheers Christian Marge the Winds are here Ah McCaine............. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

This could be an interresting discussion. The F&P has a few realy good points that make it so popular, its an efficient design, its easy to get ( well in Australia/ New Zealand at least ), and it cheap. If you had to make one from scratch it would get very expensive, the cost of punching or laser cutting the laminations would be the biggest expense. A laser cutter would charge at least a couple hundred dollars to cut those laminations, and then you still need to cover it in plastic and wind the coils. If I were to make a F&P from scratch, I would either make it longer/stacked, say 100mm high instead of 25mm it is now, or make it a bigger diameter with more poles. I would also replace the plastic component in the stator and hub with aluminum. This may be why commercial windmills like the Air-X range use the same stator thats used in car alternators, saves redesign and retooling costs to use an existing component. I do think its a subject worth looking into. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

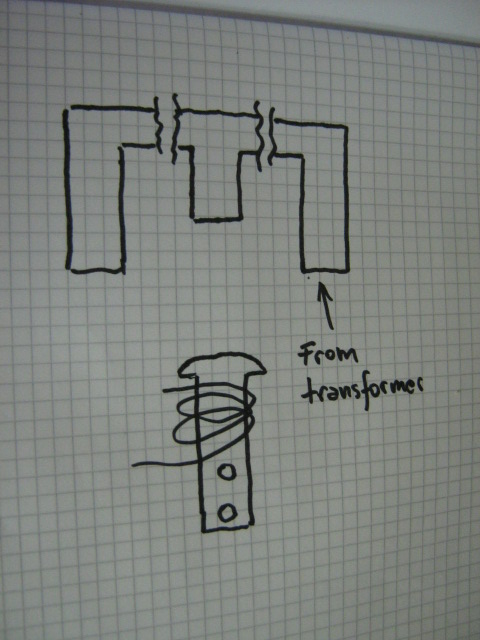

Before, I wanted to make one from scratch. My first ideea about laminations:  Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

And I think this is good for rotor. Hello Dennis, my program refused to cut the picture without you  . .

Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Or maybe not an entire F&P because anybody can make the coils and glue the magnets (ferrite or Neo). The rest can be parts to put together. So, anyone can work on his alternator and more subjects and headache for this forum  . .

---------------------- Sorry about posting again, Seeley motors have laminations? Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

BRAINSTORM PLEASE! I think we must look for scavenged ( a word learned from this forum  ) parts to build over them. And everything starts from rotor - we must find something suitable for this purpose (without magnets of course, ferrite magnets are cheap). And the rest can be designed starting from this rotor. Something wich is largely used (under our noses). ) parts to build over them. And everything starts from rotor - we must find something suitable for this purpose (without magnets of course, ferrite magnets are cheap). And the rest can be designed starting from this rotor. Something wich is largely used (under our noses).

Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Yes Seeley motors have laminatiosn, sort of. Its more of a backing coil of steel to complete the magnet flux path. For a magnet hub I think a brake drum off a old car or truck. Its strong, the cast iron will complete the magnet path. You could use the whole bearing housing and wheel flange, you just need to take out the brake shoes and slave cylinder, and fit in the stator some how. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

I think Hugh Piggott's axial flux design is an example of an effective design that is suitable for home construction. |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

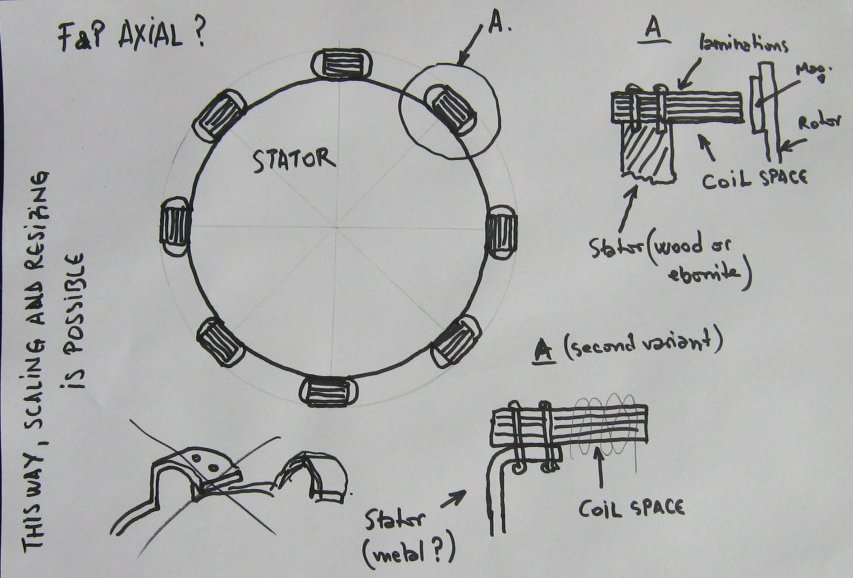

Thank you Glenn, the brake drum is o good solution, I will study this. KiwiJohn, axial flux desig is excellent (easy to build) but have a BIG problem: the stator. You can't test different combinations or reuse it. But something combined ... Axial flux design but only one rotor and stator like F&P but with coils oriented for axial flux. Problem is "sticking" to support the laminations of coils. You need a translator  . Yes, the stator MUST be like F&P, reoriented, and I think it can be done. . Yes, the stator MUST be like F&P, reoriented, and I think it can be done.

Both solutions worth looking on them Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Tomorrow I will post a scketch. Now I must go to my Church. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

Storm Regular Member Joined: 12/09/2005 Location: AustraliaPosts: 43 |

Vasi, there is a post regarding neo magnet conversions where a poster Clarence used a brake drum rotor a cars stub axle and the stator from a F&P if your interested looking. Page 9 on the back shed. Some links to his pictures below http://www.geocities.com/clarence_horatio_dexter/trailer/sta tor.jpg http://www.geocities.com/clarence_horatio_dexter/trailer/sta tor2.jpg http://www.geocities.com/clarence_horatio_dexter/trailer/rot or2.jpg http://www.geocities.com/clarence_horatio_dexter/trailer/rot or.jpg |

||||

Storm Regular Member Joined: 12/09/2005 Location: AustraliaPosts: 43 |

Ok sorry the links didn't work, you can get to page 9 down the bottom of the main windmills page. |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Thanks Storm, very informative page. This is a "must read" when do a Neo conversion. I designed this...

Few coils for easy reading. Thanks KiwiJohn, I think this is a good design for testing and experiments, but if we can find a better solution for mounting laminations on stator. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Using steel laminations is one of the limiting factors in the FP units being a 58 pole rotor freguencies get up to over 700hz at the higher rpm steel starts to cause high losses above 200 hz. My idea has always been to built a stator with iron powder or ferrites i often scout around the net to find a source, or learn how to manufacture at home i believe it is possible the powders are available and a pottery furnace would fire the pressed shape of a stator. I would likely go away from the salient design to a cylindrical design like a induction motor and spread the pole winding to obtain a flat topped waveform more suitable for battery charging . It would be possible to build a stator using the readly available brick shaped shapes produced or one e core is nearly the right dimensions but I have yet to find a source of soft magnetic materials that is reasonable prices i would nead to import China or USA Anyone know of ferrite or iron powder sources or had expeiance of manufacture we dont need that great a quality anything is better steel. Herb |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Non magnetized ferrite ? internal (ferrite) antenna from a radio receiver is good ? That kind of ferrite? In Romania, we can make a request for non magnetized ferrite magnets, http://www.rofep.ro/english/index3_e.htm Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Yeeees Herb ! I think I was blind until now  . .

Scrool this page down http://www.rofep.ro/english/index7_e.htm Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

I think for HerbNZ design is very good that but is hard to find (and make) an axle for rotor without a lathe. Also making an F&P rotor is still hard. But a axial rotor is easy. I think is good to have a poured stator like in my scketch. Easy to make coils, easy to change coils if are burned or if we want different outputs, easy to make another rotor with different magnets. This can be a good "Windmill Kits & Parts" from TheBackShed Team, like electricfield.com or ecoinn.co.nz . I think ... Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| windman Newbie Joined: 02/12/2006 Location: Posts: 19 |

i have used magnatite powder cast with epoxy some time ago to make a stator for a drum alternator works, quite well no cogging even with neos. |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

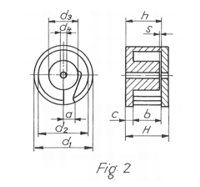

Or maybe not an entire poured stator, but this pots from the same address: Iron powder pot cores

Or something similar poured like windman said. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |