|

|

Forum Index : Windmills : Decogging F&P

| Page 1 of 3 |

|||||

| Author | Message | ||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Can someone please provide some simple instructions for decogging an F & P smartdrive motor. I have looked at the pictures in the Backshed site and have concluded I am stupid, because I'm unsure of the procedure. I have done one face (the inside) but it does not seem to make any appreciable difference: a) Is it just the top edge of the magnet that needs chamfering, along with the plastic, or do the inside edges of the magnets need chamfering too? b) Do both the side encased by the rotor AND the forward-face have to be filed? c) Is the shape critical? Look forward to your usual splendid advice Cheers Bushman |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hey Bushman Have a look at this link on the Eco-Innovation web site. http://www.ecoinnovation.co.nz/links.php?code=8 About 3/4 of the way down the page there is a section about Smart Drives, you want the 4th on called "Smart Drive Wind Turbine Applications - 420 KB pdf". Its a PDF file and goes into how Michael decogged his smartdrive motors, good read. This picture here shows a close up of a decogged motor I did. Its a big picture. http://www.thebackshed.com/Windmill/images/Dscf0548.jpg Hope that helps. These days I go for the 7 phase conversion instead of decogging. The 7 phase conversion means you need to but a new magnet hub, but the results are very good, no detectable cog. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

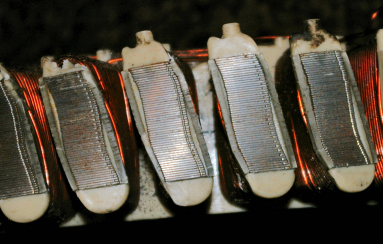

G'day Bushman, Gee mate you don't go chamfering the magnets. nothing is done to the magnets for de-cogging. The modification for de-cogging is done to the stator. The stator has Poles that stick out like fingers all the way round. The wire is wound on them. What you chamfer is the steel edges on the very end between poles. This makes the edges of the poles slightly rounded. In the picture, see how one pole has been de-cogged but the one on the left has not.

Only the long edges between poles are modified, the short edges are not touched. Hope that's helped.

was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Thanks Guys Gill - please resend the picture - it is not loading Cheers Alan |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi If grinding laminatios on the stator try to grind with the direction not across them this burrs the edge and shorts out to neighbour causing eddy current losess. Has any one tried twisting the stator pole peices I am sure they would twist up to 10 degrees. this would be a lot more efficient way to eliminate cogging. Herb |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

No doubt about it Herb the pole pieces can be easily twisted. I have a segment cut from stator and I found it easy enough to twist a pole piece with a 15" Crescent. There would be a few challenges to do a whole stator though but I guess it would be feasible with some sort of special tool that would fit over the top of the pole piece and cause a bit less damage than the spanner did. |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

A solution to twisted NEO's ? Interesting! This I want to see . Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Like this you mean Herb? You could do a much neater job with some sort of tool that would fit right over the top of the coil, maybe just a heavy enough piece of channel steel. |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

I agree making up a tool out of a bit of RHS with a through-pin as a handle sounds simple enough. The right sized section could even have a bit of padding glued inside to prevent damage. KiwiJohn -does this completely eliminate the need for filing? Alan |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

I have no idea Alan. Herb mentioned the possiblity of twisting the poles and I had this segment from a stator cluttering up the clutter under my bench. The theory sound good to me and I think it would eliminate the need for filing. But would a stator still be 'true' enough after this torture? Maybe someone could give a full stator the treatment and report here? |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Hi John When you twisted the sections with a wrench, was there any indication the material might snap? I wonder if a bit of heat would help, though too much might affect the solder. Dropping the stator in a basin of near-boiling water might be the go - enough to soften the nylon but not enough to damage the wiring Alan |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi John You certainly moved them ha. I have never done it my use is mainly hydro and my windmill was already done. but i confident it will work. a U shaped peice steel that would fit over the pole best to remove the windings i think i never reconnect much easier to rewind you usually only need most 12 turns per pole. twist them all same direction about 10 Degrees will give same effect as the new rotor does also should lengthern the peak better for battery charging . One problem I forsee is the stator may grow a little in dia and reduce the clearance to the rotor if its not much and we dont rub be good higher output, but if it does it may be we have to mount the stator in a lathe and take a scim off I would love to try myself but there is 101 other things to not enough hours in day Herb |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Looking at your photo John it would a so be better to file the plastic back that protrudes slightly outside the pole face |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

I agree it might be best to file down the top of the plastic to prevent it fouling. I'll be the guinea pig for this and have a go at the weekend. My marine electrician mate will be available on Tuesday when we can test the output and cogging at the same time. Should also have some new aluminium blades by then - with a greater root area and sharpened on the correct edge (as pointed out by Dennis recently, I got it wrong first time) I'll give you the results and some pictures next week Cheers Alan |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

I am not sure heating would gain much, the plastic is not very thick and the main effort is in moving the steel laminations, they sort of twist and at the same time slide over each other. The steel is quite soft and all that snaps is the plastic bits around the top. Of course I tried to grip the coils as near the top as possible. Looking forward to hearing your results Alan. |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Hi all After the usual steps backwards (no pun intended)the merits of twisting the steel laminations versus profiling the sides seems to have settled very much in favour of the latter. We made up several versions of a hollow box-section tool with a handle, but every one of them bent before making any appreciable difference to the alignment of the laminations. This does not mean it cannot be done, but is would require a case hardened tool to be strong enough, yet thin enough to work without fouling the coils and doing damage. Using a sharp 1.5" half-round file, I reverted to profiling the sides of the laminations as advised by various of you - problem largely solved. The entire profiling job took only 15 minutes and the half-round shape used flat-side down gave plenty of control without having and appreciable edge thickness to get in the way. I rather doubt it would be worth paying $100 plus for a power file The cogging was reduced by an estimated 70% and although it still takes some initial effort to overcome the first cog, once moving the unit picked up real speed and the voltage output was excellent The remaining problem is how to overcome that initial cog. The electrician used the 7 X 3 star wiring option and has been over the various rewiring drawings a dozen times without being able to figure out how any of the alternatived would fix the problem. Has anyone experimented with a computer-fan that would turn in the slighest breeze and be used to provide inertia to the main rotor through some simple gearing? Cheers Alan |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Just for the new forum members, on the topic of decoging the F&P, I did some work ( inspired by Bruce ) a year ago on the 7 phase cogless conversion. Its a conversion that eliminates any cogging effect, but means you need to buy a new magnet hub which adds to the cost of your windmill project. Just thought I would mention it for those who havn't seen the article. The details are here http://www.thebackshed.com/Windmill/articles/coglessFP.asp I wont use anything else now. I have two 7 phase conversions on the go and will do the same for my next windmill. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Hi Glenn Thank you for clearing that up - I had been confused by what seemed to be contradictory information and could not work out how or even why to do this conversion. Personally, I'm not sure it is worth the effort as there are other ways to overcome the cogging effect. By filing (see post above) around 70% of the effect has been eliminated. A sh*t fight nearly started yesterday on a different thread of this forum when I (and by association all of us) were criticised for "not seeing the wood for the trees" and that cogging was irrelevant when overcome by blades with a larger root area. As much as I disliked the tone of their comments, these guys have a point in that the information on the backshed site is not well organised and to find anything, one has to work through a considerable number of pages and inconsistent cross-links. I certainly had never seen their material despite much searching and the same applies to their previous comments on this forum dealing with the cogging issue. I am not being critical here - I specialise in Information Management and appreciate just how hard it is to retrofit a search/archive function when it means indexing and reclassifying virtually all of the data. All up, I reckon you do a great job and I have learned a lot from you - in turn, trying my best to contribute as much as possible Cheers Alan |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

I saw that reply of adelaide long time ago and I want to try that solution (Is so good to have an F&P from Kiwijohn and thebackshed team). Is also a solution when you make a propeller blade from wood and you don't have a wood with long enough width. Now I have my own internet connection (dial-up) but on that time I was forced to download entire site to browsing offline (helped by a cousin of mine). The Back Shed site is very well organised but the forum is like a chat room, the last article is first. Can't be organised more than it is already (an example - two topics with the same subject  like your topic and another one) because of human nature. like your topic and another one) because of human nature.

Don't be upset. For decogging, filling is a solution, Glenn and Bruce have another solution with a new type of rotor, Adelaide have his own solution with a propeller with good torque (Dennis have propellers with 5 or 6 blades and Glenn tested Lenz turbine on a non decogged f&P), also Herb came with a new idea of a twisted laminations and all ideas and people deserve their own topic. Just look on Seeley motor topics, the "false fight" between Dennis and Bruce ... Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello Alan. Don't be 2 upset about what other guys say,,I've had my dose of being 'told" ,,but with 63 years behind me ,lots of this critical feedback gets stored in "the back room" . Dennis , Aaron,and a few others have given me hell at times ,but after the dust settles we all get back to doing what we know best --playing with windmills. We all help each other,just have to look beyond the different ways other guys and ourselves say things. By the way ,,see if you can get a new F&P stator and rotor, do the re-connections the way Glenn has written them and you'll see a marked improvement in 'spinning" ,,not so much in output. I've made a Neo magnet rotor that suits the old stators,it certainly performs well in decent wind and recently I'm impressed with the big plastic blades I've made. They certainly overcome the cogging ,but will require some mechanical braking system ,I feel , in strong winds. The Seeley ,, looks like we are heading down that path in the next couple months ,,3 or 5 of us figuring out different ways to mount and spin them,should be interesting comparing Seeley against F&P-- time will tell.. all the best, crew. Bruce Bushboy |

||||

| Page 1 of 3 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |