|

|

Forum Index : Windmills : aluminium chinese blades

| Page 1 of 2 |

|||||

| Author | Message | ||||

| kumtarest Newbie Joined: 01/08/2007 Location: AustraliaPosts: 7 |

hi i am a first time user .i thought you would be interested in those aluminium chinese blades for $99.00. i just purchased a set and they arrived today they are made of extruded aluminium and the red tips are solid hard rubber .i think they are worth the money .i will hook them up to my mill soon and see how they preform . |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Spot on kumtarest Here's some further info with more to come. Blades arrived. Pleasant surprise to find they are not solid but are extruded. I would rate the extrusion as quite good. Very light with a good finish though 95mm shorter than the old glass blades. weight 700g ea (glass 1,300g ea)

Comparison:

It's what they do to this quality extrusion that tells you it's Chinese. The tip (red) is a plastic moulding that is inserted into the extrusion. It is held in place by centre punching the aluminium, 2 on top n 2 below. God knows how these dimples stop the tip from flying off in a good spin cause I don't. Oh yes, a big gap on each is where the tip doesn't fit properly, but on the bright side, it gives the native bees and wasps somewhere to build nests.

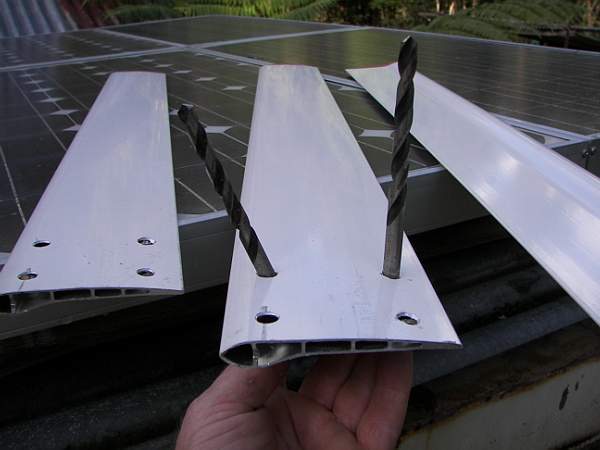

now the mounting holes have a few issues too. First, the holes are not the same dimensions. Old holes were 60mm wide x 60mm long CtoC, new holes are 60 x 45. Holes may have been drilled or chewed, not sure which. ("Grandfather Chan bought drill bit.. and looky... still workey.") Axis of drill is vastly different for leading and trailing holes. See Pic. no added support in hole area, and bolt clamping may crush extrusion or bolt may pull sideways through the thin wall thickness as blade spin loads the root.

Still I would cope with all these faults "IF" I can get a twist in it. As I said the extrusion seems OK and I feel potential for a twist looks Vgood. Will need to carve/shape 2 x clamps and devise a setup to twist yet maintain axis of blade and ensure consistency of the 3 blade twists. Stay tuned..... Will post to forum when bent or busted. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Feral Newbie Joined: 03/12/2006 Location: AustraliaPosts: 39 |

Gill, How long and how much $ ? Fill the hollow extrusion with epoxy putty, plumber "Ferropre" or car bogg. Cess back on 9th. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Feral, Tried to get to it last weekend but got caught up. will try to put some time in on it this weekend but no promises. Purchase price was $99 with postage sydney to Cairns of $35, so all up for me $134. I'd say either of the 3 products would fix the possible crushing problem OK, though I feel not as good for the possible tearing through problem. I am inclined to dip into a small rectangular mould of resin. There by filling inside to just beyond the holes and also forming a flat clamping surface on the outside too. The section formed would look something like the root of a wooden blade. Though likely dozens of approaches to this one.  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Fill profile with sand before twist and warm with a torch. But I think is hard to do. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Thanks vasi, sand is good idea though do not like the heat idea. I've had too may disasters using heat on aluminium, and I don't think it helps at all, so will pass on that one thanks. Filling with sand will not be difficult if I can find some dry stuff. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Chris Senior Member Joined: 12/09/2005 Location: AustraliaPosts: 146 |

where did you get these blades from? |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Chris, Near end this thread was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

It works! I've twisted the Chinese blades to 30deg. I felt that was a far as I was game enough to try. To get 30deg, the blade has to be twisted to about 70deg then it spring back when released. Finished product:

"The TWISTER":

30deg:

I'm prepared to twist blades for any forum member for free, provided you accept my no liability, and you pay all potage, conditions. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| kumtarest Newbie Joined: 01/08/2007 Location: AustraliaPosts: 7 |

Hi Gill great twister machine . By twisting these blades does this mean that the red plastics ends will end up parallel with the center hub and give better speed and better start up . I am only new to this and still learning .thanks kumtarest |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day kumtarest, Red tip parallel with HUB? Yes almost. The chord at the red tip will be just off perpendicular to the axis (maybe 3 or 4 deg blade angle) and the blade root chord will have a blade angle of 33/34deg off perpendicular.

You are right also in deducing a better speed and startup. All due to the more efficient blade angles at the various stations along it's length.

In the unmodified factory state the blade root will always be in a state of stall no matter what the prop speed and whilst large angles of attack are unavoidable and tolerated(without variable pitch), this greatly exceeds reasonable levels. Hence the modifying twist .

was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Feral Newbie Joined: 03/12/2006 Location: AustraliaPosts: 39 |

Gill, Do you beleive that by twisting you have made the blades stiffer in the overall length ? Could they be longer or extended to get more power out of the wind by having a larger working area ? |

||||

Storm Regular Member Joined: 12/09/2005 Location: AustraliaPosts: 43 |

Feral, you could most likely extend from the root to give the larger area required |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Feral, I had to go and check strength over their length as was not aware of any significant change. I am surprised to find them slightly stiffer. I cannot get them to flex like I can the unmodified blades. Yes to increasing size. Glenn put the idea forward of extending the hub with rod and attaching the f'glass blades to them as a way of increasing the swept area. This bypasses the need for larger angles at the root a well(cannot twist glass blades to a new shape). A few commercial wind gens use this approach and I think I will also, as a way around attaching blades at the 30degish angle to the hub. Having them adjustable would be easy to incorporate in the design, handy too. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| wllewellin Newbie Joined: 16/01/2008 Location: AustraliaPosts: 4 |

Hi everyone, i thought i would share my experiences with the chinese turbines. First turbine from Jaycar, hub was machined off centre and led to vibrations that ultimatley led to the tail plane to fail and the fiberglass blades to start to fail. Second turbine from envirowind was a newer design, smaller and with aluminium blades. We didn't use either of the supplied towers as they are s**t and too low anyway. After 4 weeks the aluminium blades failed at the hub, these were replaced by envirowind and the second pair lasted 6 weeks when they too failed at the hub, on taking down the turbine the cast housing had fractured around the tail mounting and is now goin to be used on a VAWT. The original turbine now runs a set of blades from the states on their own hub ($125 oz inc s&h) and a ss tail which seems to be quite satisfactory. |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day wllewellin, And that's the place he likes best, I'd reckon. Good to have you join the forum and share those horror stories. I am in the process of making a 6 blader using the Chinese aluminum blades. Some precautions I'll be taking will be to strengthen the blade roots by part filling the extrusion cavities with a two pack filler, by bedding the blades to the hub with sikaflex, and securing the plastic tips better. I feel if a tip comes off or the root walls are crushed a little, or not tightened enough, the resultant looseness will cause vibrations that will metal fatigue the aluminum in quick time. Loose a blade and the massive out of balance will flick the tail around causing it to break off, The yaw bearing and any other weak point is also prone to fail. I think your experience is a good warning to me(and others) to take extreme care when preparing and securing these blades or any blades for that matter. Sharing your story much appreciated. Thanks. As a side note, when posting pictures, press the ENTER button a few times before between uploading them. This puts each of them a new line. moregooderer.

Picture size is excellent. Bit of a wind farm you've got there. What's the output in peak conditions?

was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Faust Newbie Joined: 15/02/2008 Location: AustraliaPosts: 15 |

Hello everyone Today I ordered a set of China-made Alu rotor blades. I hope I am not making a mistake... I intend to use them with a F&P based wind power generator. I guess, mounting them to a hub is critical. Any info on mounting these blades is very welcome. Gill's bending machine is impressive. I guess I can come up with a wooden version myself :) Otherwise I take up Gill's kind offer and send them to Cairns. Is it a good idea to file the mounting side cavities of the blades with epoxy or hard foam ? cheers Faust in Melbourne |

||||

| Feral Newbie Joined: 03/12/2006 Location: AustraliaPosts: 39 |

For those who are interested in a more efficient method of directing the blades of the vertical rotating generators. Download the interactive VSP file on the bottom of the page at the link and you will understand how this same system could be used to produce a very efficient system for the vertical rotors. http://www.voithturbo.com/vt_en_pua_marine_vspropeller.htm Those who are not happy with the strength of their blades could use the carbon foils produced by Fasta Craft.  |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Faust, Nice to have you enter the forum. I can see the windmill bug is still bighting people. I wish I could give you more information on improving those blades but I have been diverted from that task to a PWM controller(still in progress) and then an anemometer with digital readout (Calibration and installation this week) but I'm hoping to get back to it soon. I'm not sure what your hard foam is, though I feel you can't go wrong with epoxy. The difficulty will be to only fill the extrusion to say 20mm past the holes and to get each one the same so as to not upset the balance. The offer of free blade twisting still stands if you decide to go that way. The member contact feature on this Forum mostly doesn't work so if you want to contact me it's gilljadams[NO]@[SPAM]hotmail[TA].com Feral, Excellent length sections and top strength as you say. I wonder if they'd do them with a twist and taper on special order? was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Feral Newbie Joined: 03/12/2006 Location: AustraliaPosts: 39 |

Gill, Did you down load the demo file I referred to as you will see the implications of this mechanical device and how it could be adapted to a vertical axis wind generator for improved efficiency. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |