|

|

Forum Index : Windmills : Update on my mount for the Baldor

| Author | Message | ||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

Hi Guys Hi Guys

Could you please have a look at these pictures,I have made some alterations and would appreciate any ideas before I weld it up !! Also using the excellent info on the site I am planing on building the tail boom next, I am not a maths wiz! so I was thinking around making the tail length around 1 meter 500mm and the blades ,which I have fond some 6"" plastic pipe at work for free around 2 meter,s long. Going with plastic mainly down to weight. Thanks and any advise greatly appreciated. Phil UK   |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

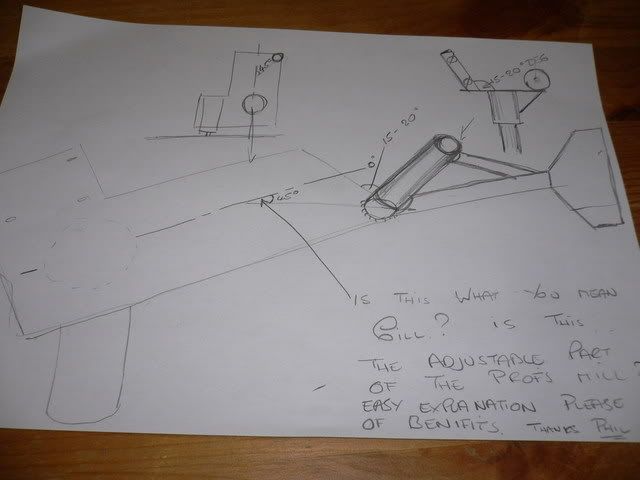

G'day philmountains, Just quiring your furl pivot. In the pic it seems to be angled 20deg but only directly back. If this is so, there will be no weight acting against furling. Check this sites bit on furling and the diagram shows the pivot as being 20deg off vertical and at 45deg off front to back axis. In your pic the top of the pivot pin will need to be moved further out to the left. Perhaps by cutting the back tack weld and pushing down on the plate to bend it downward? May break the side tack welds but I hope you can understand what I'm trying to say. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Here's a ruffy of how it could have been made. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

Thanks Gill,I printed off your diagram,which made "Furling" a lot easier for a novice (like me)to understand than Hugh's book. Thanks Gill,I printed off your diagram,which made "Furling" a lot easier for a novice (like me)to understand than Hugh's book.

I did not weld up up the Yaw bearing,as I did not know if it needed 45 degree to work, you have now helped me to push this project along a bit further. I will grind off the tacks from the pipe/Yaw bearing to the plate and set it to 45 degrees tomorrow night at work ,I know this is not what you had in mind but it will give me 45 & a 20 degree angle is this still right ? Also Gill what do you think to the length of the tail boom @ 1 meter 500mm(I pinched this length from your Ref on Furling)

Thanks again Phil Here are a few more pictures a couple of the blade/prop mouting plate I made up and the last of another smaller mill with a bade set up I found in a old chiller unit, This will need a bit more work on the blades before it will work I guess !!!  I love to see other people ideas so here are some of mine I love to see other people ideas so here are some of mine

Thanks again Gill for your help. Phil |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Phil, Looks like your on top of the basics of the furl pivot now. Great stuff. Sorry I erred and referred to it as the yaw pivot earlier but you picked up on what I was meaning anyhow. Now edited and correct. As to boom or tail length, I have not commented on this as don't know your design/setup. Would like to see calculations for designing tails. I am one day posting "ideas on tail design" to bring out areas not covered in existing material. It is my opinion that tail length, area and angle(yes angle) are first needed to balance prop area and offset and only then should we look at furling with it's pivot angles and weight. One day soon I hope. Until then we'll just use 'best judgement' for these parameters and work with that. In using 'best judgement' I suggest you consider: Build with minimal and light weight materials. If to heavy, tail will furl late and it's difficult to remove weight. If to light it will furl sooner but weight can always be added. Larger tail areas and longer booms are like to much money, no big dramas, but small tails or short booms can not respond to wind changes as required and it's harder to get more than to give some away. Keep up the good work, still a ways to go yet. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

Hi All I have managed to do a bit more to the project this month,Not too sure if is all OK though ? Firstly I welded up the yaw bearing angle to what I thought was 20 degrees found out today it pulled whilst welding and is now 28 degrees !!! is this a big problem ,do I need to light up the cutting torch !!!!!!!I wish i had made his with a hinge mech now as it took me ages to try and get these angles(what does the 20 degrees angle affect sorry to be ignorant  ) )

Also the boom and tail weigh 10 kg is this far too heavy ? I used 3/4 inch red band tube ,I was worried it would bend, now I am worried it would need MPH wind to furl this weight !!!! Thanks again you guys for all your help and advise Phil in the UK

|

||||

Trev Guru Joined: 15/07/2006 Location: AustraliaPosts: 676 |

Phil, Those angles look way to much. I guess you have seen the way it is calculated. Have a look at http://www.thebackshed.com/windmill/Docs/Furling.asp Everything needs to be kept in perpective. Trev @ drivebynature.com |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Phil , Afraid I have to agree with Trev. I'm thinking you may have got the 20deg and 45deg mixed up? That's 20deg off vertical in the direction of South West(for your mill) With a tail of 10kg and that 28deg(looks like 45deg) you will need a massive wind to furl. I think best to give it another go. With a 10kg tail weight i'd even try 15deg. For the tail I use old aluminim road signs. other than that I'd try 1/8" marine ply. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

Thanks Guys for your advise,a bit sick, but knew it was going wrong. Can I just recheck with you before I do some serious gas axing, 15 to 20 degrees is the side angle and 45 degrees is the tilting back angle  . .

Also was thinking about tail boom weight, I was thinking of trying to use ,say first five inch, cuttng out then welding in some thinwall ? by the way the tail is made from a spare sheet of perspex that was laying around !!! its so hard when dealing with scrap builds !!! Thanks again for your replies Phil |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

No, that does not sound right. Lets try a different approach. Say the prop is 12 o'clock, the tail is 6, right is 3 and left is 9. Now start with the furl pivot shaft at perfectly vertical. Now move its top in the direction of 7:30 until it is 20deg off vertical. The leaning tower of Pisa looks to be about 5 deg off vertical. Note that 7:30 is 45deg to the left of the front to back axis as seen in a plan view. Yes I know the difficulties of free resources meeting the project specs. So often things are a compromise. The boom pipe size reduced to thin wall sounds good. Can you maybe step up the size a little for strength whilst still reducing weight? was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

Hi Gill Thanks for sticking with me, is this right ? I Think it is sinking in at last

|

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Read this page and after that, will be easy to set up the furling system: The link Regards, Vasi Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

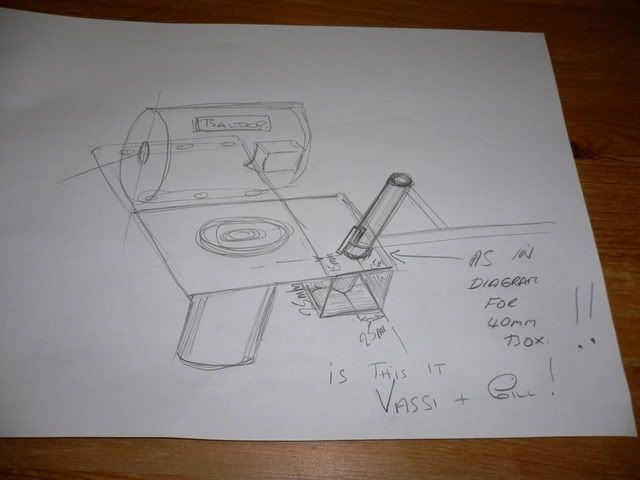

Thanks Vasi I looked at this link ages ago and forgot all about it ! Some things get stuck in my brain and  you know what I mean . you know what I mean .

The tail boom appearers to me to be made out of 1/2""(ID) steel steam /red band pipe am I right ? Also with this new idea you have given me would there be benefiting having the box in mt drawing be free to slide east to west(across) still thinking about the Professors mill. Thanks Phil

|

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

The sketch is looking great. Here another aproach for furling system: PDF file Ed from www.windstuffnow.com have a kit with complete documentation: Making the blades Wiring the turbine P.S. The methode you are using now is Glenn's work, so credits .... Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Phil, Here's how I would have drawn your first sketch. I see your second sketch just shows measurements. If they are from Glenn's plans on this site then that would be correct. You say you used Steam pipe. Isn't that about the thickest wall section you can get? No wonder it weighs 10kg. You'll have to stop thinking in terms of battle tanks and bulldozers and bring your designs more towards aircraft construction. Try steel conduit? How about very small exhaust pipe? I have used a TV antenna "hockey stick". You know the thing that screws onto the facure board that the TV antenna gets clamped onto? Perfect! was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| philmountains Newbie Joined: 17/01/2006 Location: United KingdomPosts: 24 |

Thanks to you both and Glenn, I have at last got it ,sorry to have taken so much of your time Thanks to you both and Glenn, I have at last got it ,sorry to have taken so much of your time

Glenn I was born and bread on Red band pipe, and I know were your coming from now, there is some thin-wall 3/4 tube at work which is just what your leading me toward,s so thats the way I will go in the next month when I get time !! In the UK we say third time lucky don't know if you have this saying in Aus & Romania ? Thanks again to you both for your help Phil  |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |