|

|

Forum Index : Windmills : NEO DUAL 48V

| Author | Message | ||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

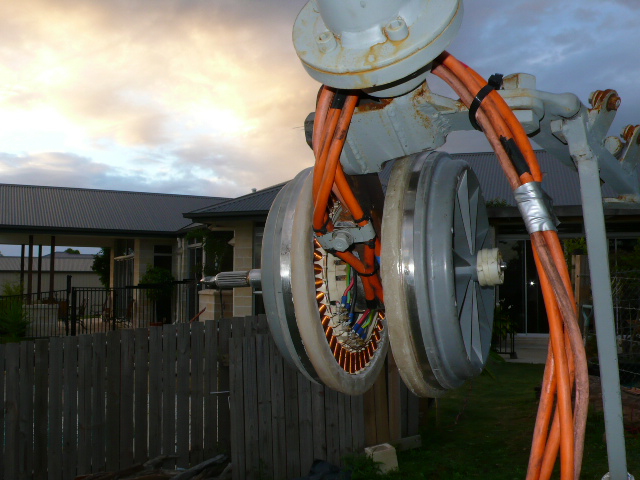

Hi All, Heres some pics of the Neo Rotors I have just fitted to my mill. Results are very encouraging , in approx 7-8 m/s I was peaking at 500 to 600 watts . The generator noise is down to almost nothing and starts making amps at approx 100 - 120 rpm in delta , star is almost useless as cut in is to low 50 - 60 rpm . Would really appreciate if someone out there would have any info on a blade RPMs / wind speed set up ? ...Phill ...

Rear Neo

Front Neo

PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Jon Bennett Newbie Joined: 01/11/2007 Location: AustraliaPosts: 27 |

50-60 rpm cutting would be good for VAWT, do you have any pics details of the fit-up process. thanks jon |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Very impressive  I'm jealous I'm jealous

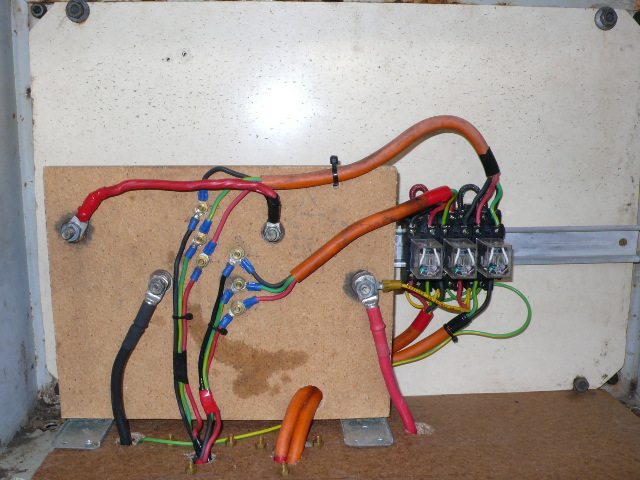

Neo rotors are a bastard to get right. 1 Did you use a template to space them? 2 What size magnets are they? 3 How does the cogging feel? 4 It appears that wiring pic is of star/delta how is that switched? auto or manual? 5 How are those stators wired? Looks nice and green up there.

Central Victorian highlands |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Very neat looking conversion, and it sounds like its making good power. Keep us posted on how it goes. I realy like those blades ( and the pool  ). ).

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Feral Newbie Joined: 03/12/2006 Location: AustraliaPosts: 39 |

Fillm, Have you still retained the metal backing behind the magnets ? |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi All, To answer questions asked .. John - I did not take any pics while doing the rotors , but for a vwat set up I would assume it would have to be big radius and vane to get the low torque, you can get the same low cut in with a standard F&P dual by series on the 3 phase bridge recs, my origional cut in was similar but at .2 amps @ 65rpm approx at 48v, at lower volts it would be much lower in a 7 pole config .... Vic - yea it is a bit tricky but you get the hang of it after a while , cir-divided by 56 gives the space distance , then to work out spacers depends on the magnet size , and the mag face is a different radius to the base, I used 6x6x13 x 156 but a larger neo would be better, I still have a clog but it is a lot softer hence the reduced noise , these rotors have had the mags removed and assembled 5 times expermenting with different angles , I had no clogg at 28deg but only 10 to 15% power increase , has something to do with field colapse. If blades are big and efficient then clogging is not an issue , the issue then becomes producing more power at low rpms in a star / delta so the only way gens insrease output is increased field and increased power input [ more efficient blades ] is my angle and the road I'm on at present.. No my star/delta is not auto i would like to use ac frequency to switch it like eccoinn's switch but I have not come to the conclusion to run the neos in straight delta with smaller blades or go bigger and use star/delta on a freq switch but on seeing the output the other day in moderate winds I feel this set up has the potential to produce over the 1KW in 10m/s... Feral.. Yes the metal band has to stay when you knock the mags out , also the rotor then becomes weak and can not keep shape with the increase in mag/field force when put on the stator , it has to be reinforced... PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| ericvr Newbie Joined: 24/11/2007 Location: AustraliaPosts: 37 |

Hi, I am new to this forum and would like to add my twopence worth of info and questions. I am helping my brother in law setting up a new wind generator system. The system is a 48 volt system with a 1000 watt wind generator and a 5000VA inverter, the battery bank is made up of 12 Volt 88 ampere hour batteries connected in series-parralell to obtain 48 volt at 480 Amphour capacity. I have made up a monitoring box with a couple of digital LCD panel meters for the voltage and the current monitoring. I will post some photo's on the site when I get the photo's done of the installation, (could be a couple of weeks though), I bought the LCD panel meters on E-Bay as well as the 200 amp current shunt, the meter s cost me about A$ 25 each including postage and the current shunt was about A$ 15 or A$ 20 each including postage  . Money well spent!! . Money well spent!!

I put it all in a plastic box from Jaycar. If anyone requires more info on the digital LCD panel meters I will gladly provide the info. The question that I have is: how do the home constructors of wind generators make sure that the cable from the wind generator down the pole does not get twisted up as the wind generator turns on it's horizontal axis as the wind generator turns through 360 or 720 degrees? Just watching the elections on TV 24/11/07 21:30 limited greenie |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Hi ericvr Use the search function for slip rings. You may want to start a new topic on your setup

Welcome aboard Phill this is a rotor I did about a year ago, I was meaning to put in three lines all up but never got around to it, perhaps over Xmas. Mine are 10mm square 3mm thick set two high. I got a blacksmith to make me a band which fitted around it and epoxied it on. Still ok 1 year on. Only 200 watts though, I have the magnets but no time to put them in. I don't have a pic of it but the final one had three lines of magnets with each one slightly staggered to the right, I'll try one more line and see how the cogg feels.  Central Victorian highlands |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Matt ,a friend from Vic visited me some time back ,bringing with him some neo's .. We stripped out the ceramic magnets and placed the Neo's around at a small angle ,say,10 degrees. Then gaffa taped the inside to form a dam and poured polyester resin. It has worked perfectly ,and now I'm about to make a second one for my new Dual F&P. Bruce Bushboy |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Bruce, that's very interesting. Your angles look very different to Phil's. I wonder which one coggs less?

You're not far from him, might be an idea to compare. Central Victorian highlands |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Heres some pics of the neo dual , the output so far has been very promising but needs good wind to start .. Have seen 750w easy in 35+ klm but where I am trying to get the big improvement is in 10 to 20 klm . Have had Glens pic logger on for a couple of months now and hve made a new set of blades which started at 3.8m dia , they were to big and flexy and hit the tower so they are now down to 3.3m and seem to be going Ok .Being able to see the difference in start up wind speed and output at different wind speed is execelent for tuning the blades. There is definate problems with rotor strength even with the resin strengthing I moulded on , after sitting for a period in one position it can distort slightly and start to pole out. Rotor strength is essential , any way will leave my bit at that and its good to see others going down the neo path as there are big gains in output to be made as long as the input power is there , good wind and good blades... Regards Phill PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |