|

|

Forum Index : Electronics : Help - I've fallen in love with a T12 soldering system... :)

| Author | Message | ||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8460 |

Unless you are already using something better, get one. I don't think I could go back to any of my other irons now, temperature controlled or not. - Heating from 25C to 325C in about 8 seconds. - Heating from a standby temp of 160C to 325C in about 4 secs (but solder is molten and ready for use well before then). - A nice, quiet beep lets you know when the tip temperature has reached the setpoint. If it annoys you then you can switch it off. - I now have 6 different tips that I've picked for different purposes. Just pull one out and push the new one in. Done. - After calibration with a soldering iron thermometer it's only a few degrees out from about 100C up to almost 500C. - 75W at the tip of the iron, not heating the shaft up. You can go from soldering a 0805 to the tab of a regulator with no pain. :) - Switches to standby temp after being left alone for 3 mins. - Switches itself off 5 mins after that. (both times and the standby temp adjustable). Just click on the encoder knob and it will turn on again. - Continuous readout of the set temp, current temp and power level fed to the iron. - There are loads of different tips available, some very specialised. - You can customise the system to what you need (I swapped the handle to a slimmer, lighter version with a shorter handle-tip distance to make precision work easier). And this is only one of the cheap models. I'm probably preaching to the converted on here though. :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 351 |

Been using them for years. I won't go back. :) I have had problems with the soldering iron not recognizing a new cartridge until it had been power cycled at least once. My KSGER is my go-to station. |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8460 |

This is a Lefavor. I got it having seen a stripdown on a forum. However, the only similarity is the aluminium front plate! Case is tubular, his is 2-part. Controller module has LCD on ribbon, his is soldered module. Power supply is different design entirely. IEC on mine is soldered to male header pins on the PSU, his is wired. It needed the earthing seeing to but leakage wasn't appalling anyway. New tips are recognized ok but there is only one set of calibrations so in theory you should recalibrate for every tip change - but that ain't gonna happen. :) The only thing missing is the boost function - that would have been nice to have. It does have a silly bug and doesn't work as the instructions say it should. A press on the encoder brings up the menu. You can't double-press to go into standby or 3-press to switch off. I can live with that though. There is no cold junction thermistor in the handle and you can't read the chip temp. I wonder if it actually is using PID or if it's a cheap analogue system with a micro fir non-critical stuff? lol I'm not going to reverse engineer it to find out. It works anyway. Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| SimpleSafeName Guru Joined: 28/07/2019 Location: United StatesPosts: 351 |

Yeah, (displayed) temperature is relative. I see what it *says* and I'll take that with a grain of salt. As long as it stays at the temperature that I've selected... I can't remember which one it was, but I had one iron go in to thermal runaway. It got tossed into the trash. And the tip issue was with my TS100 soldering iron. I'm not sure what the KSGER would have to say about it. Looking at the Lefavor and the KSGER, they have some similarities. Not twins separated at birth, but along those lines. I'm of two minds when it comes to grounding. If I'm doing electronics at home it's a good thing. If I'm over at my buddies shop, where he has his ground somehow elevated to 60 volts, it's tends to be a bit of a distraction getting zapped while trying to solder. :) |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8460 |

The glowing tip issue will be a "feature" of any of this sort of system if the mosfet fails short-circuit or gets stuck on full output due to a feedback problem or software failure. Just something we have to live with. At least the tips are easy to change. Even the control module can be swapped out without too much difficulty. It would be most annoying if an expensive tip was ruined though. :( I was SMD soldering on my aquarium controller rebuild yesterday. I'm really happy with the OSS handle and Quicko tips. :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2951 |

There isn't much you can do about a shorted MOSFET but if the gate drive is PWM rather than just switching on/off around the setpoint there is a mod to prevent full on. Add a capacitor in series with the gate drive and from gate to source add a bleed resistor and reverse biased diode. The R & C values set the maximum "on" time and the diode ensures the capacitor discharges fully during the "off" time. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1214 |

Interesting for the price, depends on which version, I was looking at the tips available and initially thought they would have quite abit of thermal mass but it looks like don't, some soldering requires a fair bit of reserve when the copper is large or thick on the pcb obviously, just asking I assume the heated tip will react fast and large thermal mass is not so necessary? It would be great if it could solder large terminals to a pcb or large caps, in what we would expect as a reasonable time for this type of work? Edit: Still have the old National Scope Iron, needs a new carbon brush and tip, but I remember the heat would disperse fast when soldering large diodes  Edit, perhaps that makes more sense now  Edited 2025-05-16 18:55 by Revlac Cheers Aaron Off The Grid |

||||

| Mixtel90 Guru Joined: 05/10/2019 Location: United KingdomPosts: 8460 |

That's the point really. The thermocouple is right next to the tip, with the heater immediately behind it. Your "reserve soldering power" is effectively in the power supply rather than the thermal mass of the tip. With a low mass the response time is very fast. You can watch the percentage of the power rise when you put the tip onto the joint, while the temperature doesn't move. I've not really attempted to solder anything big yet, but the lugs of a 20mm fuse holder and the fixing lugs of a USB-A socket simply didn't have any effect. A wider tip is better for those than a tiny one, obviously. I found that the extremely common but unpopular K ("Knife") tip is actually rather good for de-soldering stuff from a pcb. You can de-solder both ends of some components at the same time. :) Mick Zilog Inside! nascom.info for Nascom & Gemini Preliminary MMBasic docs & my PCB designs |

||||

| davros Newbie Joined: 24/02/2025 Location: CanadaPosts: 30 |

I have been using one of these for years now , managed to snag an original cable which makes it really sweet http://kair.us/projects/weller/index.html |

||||

| oreo Senior Member Joined: 11/12/2020 Location: CanadaPosts: 123 |

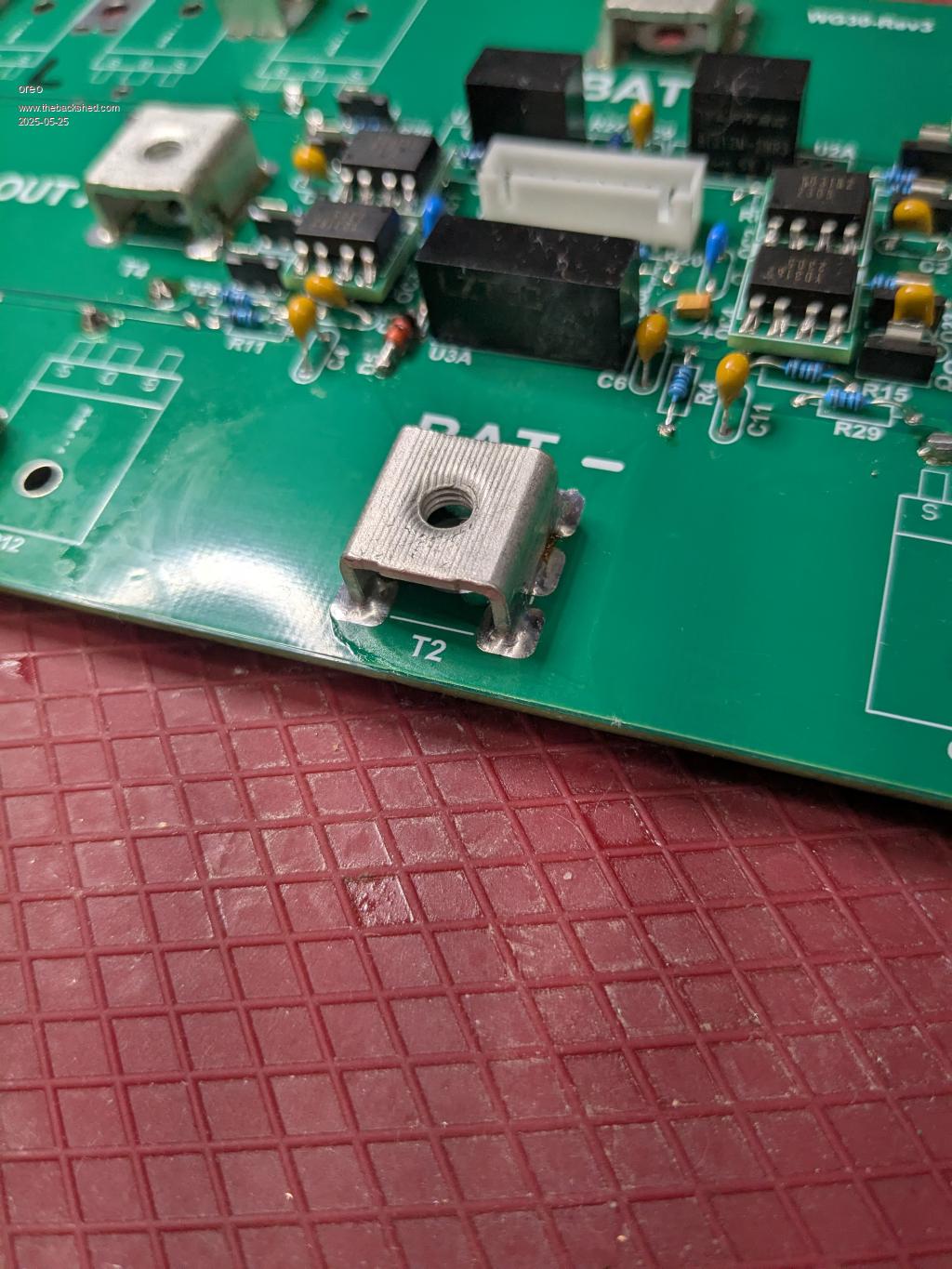

Wow, that is the first I have heard of a DIY soldering iron. Nice! The T12 units look interesting too. I am currently using a Hakko FX-888D which I upgraded to a couple of years ago. It does not heat up nearly as quickly as the T12 system does, but I like that the larger tips (5.2mm) will solder heavy parts pretty well. When soldering the 130A terminals on the Wizeguy power board, the FX-888D (65w) performed far better than my wife's Weller W100P (100w) iron that has a giant tip and is used for stained glass.  If I ever need to upgrade again, I will need to consider some of these other options. Greg |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |