|

|

Forum Index : Electronics : Investigating MOSFET drain connections through the heatsink

| Author | Message | ||||

| Zathros Newbie Joined: 20/09/2024 Location: United StatesPosts: 6 |

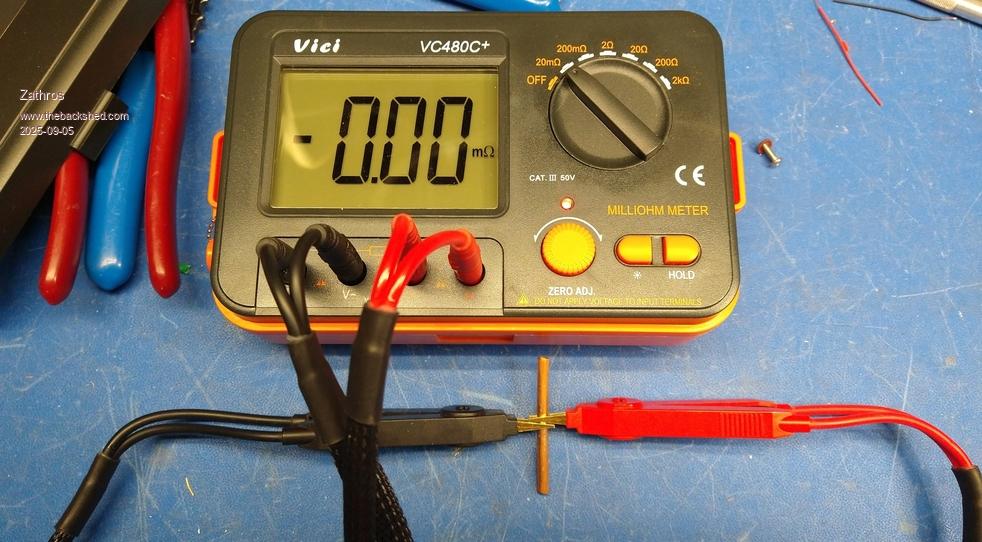

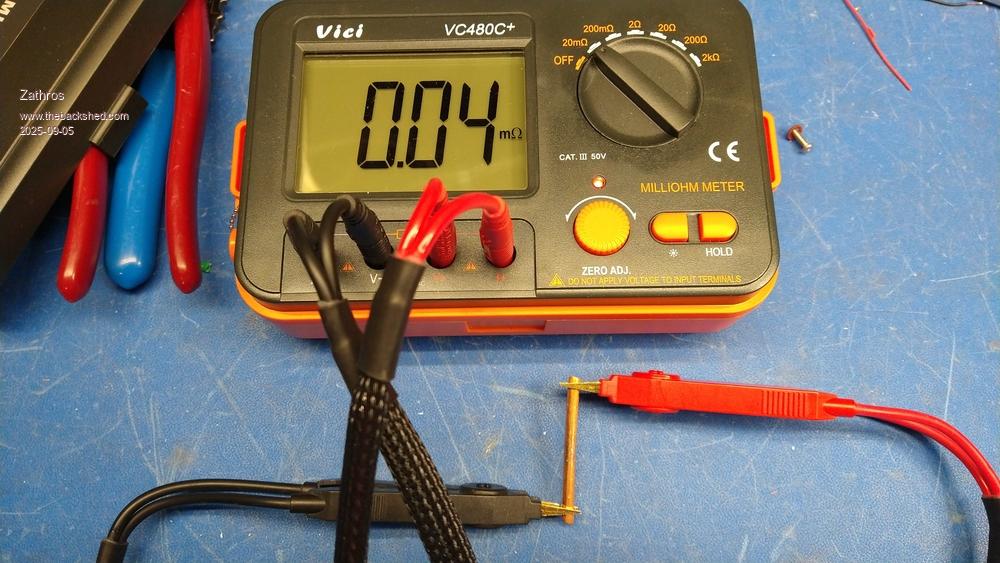

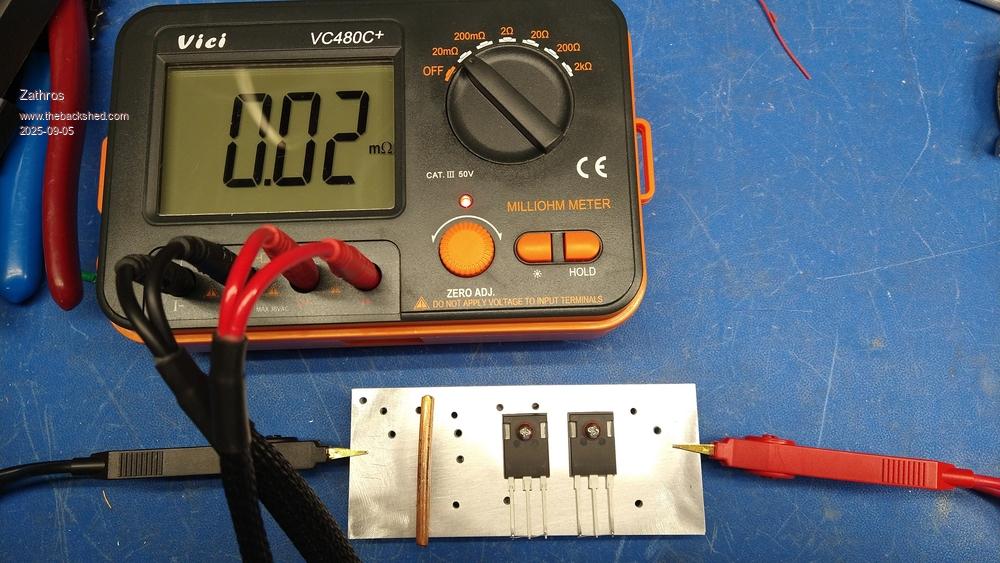

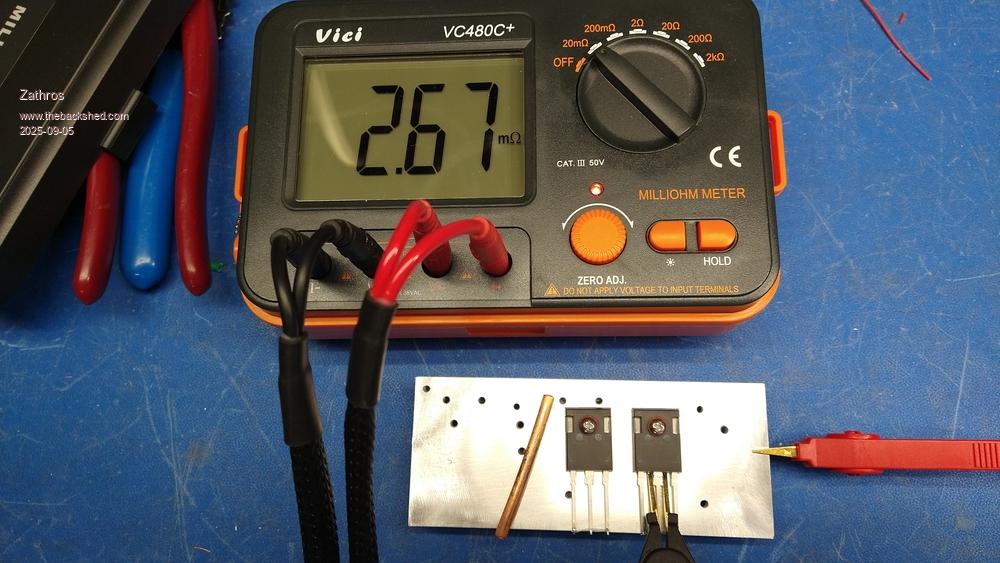

Hi All, I'd like to share some information I measured a while back when setting up China sourced inverters using the EGS002 driver board. I started experimenting with inverters after getting inspired by all the great info on this site. Many of the China sourced inverters use the heatsink as an electrical connection, either for the + connection to the high side MOSFETs or for the LF drive to the transformer. Using the heat sink as an electrical connection to the MOSFETs has always seemed questionable to me, at least the way the China inverters use a dry connection. This test measures the resistance between the heatsink and MOSFET drain tab both dry and with GB Ox-Gard applied like heatsink grease. The compound used between the MOSFETs and the heatsink is GB Ox-Gard anti-oxidant compound. From GB marketing: "The Ox-Gard Anti-Oxidant Compound is the perfect safeguard for aluminum-to-aluminum, aluminum-to-copper, wire connections, and aluminum conduit joints. This product is formulated with metallic zinc to create a compound that enhances electrical and thermal conductivity which is used on high power crimp connections and stud bolt mountings. When the connection is tightened, the grease is displaced, leaving a layer of zinc filling in the surface imperfections of the interface. This has a twofold effect; it improves electrical conductivity and it improves thermal conductivity. This reduces the connection temperature under high power conditions by a reduced voltage drop and by providing a heat conductivity path to the connection's substrate. Manufactured with a unique grease compound ensures brush-ability over a wide temperature range, tenacious adherence to all surfaces, resistance to water wash out and the prevention of rust and corrosion. " Normal white heatsink compound is silicone oil loaded with zinc oxide. The GB Ox-Gard is a lithium grease loaded with zinc powder, talc, and graphite. I had reciently purchased a Vici VC480C+ milliohm meter from Amazon and decided to see what could be measured. For the money, the VC480C+ is a quite capable meter. For zeroing the meter, I've been using a 2" long chunk of 6ga (16mm2) wire.  The meter is sensitive enough that if you zero the meter with the clips close together, then move the clips to the ends of the wire the meter measures .04 miliohms. The measurement is quite repeatable.  The test heatsink was prepared using a benchtop disk sander to remove the aluminum oxide layer and flatten the back. Final prep was hand sanding using 5" diameter 150 grit followed by 220 grit self adhesive sandpaper stuck to the top of the cast iron deck of the table saw. The meter uses 4 wire clips so back side of the heatsink also needs to be preped in 2 spots where the meter will be connected.  For checking the meter connection to the heatsink the clips are connected to opposite ends of the heatsink.  The drain to heatsink resistance was measured with 1 lead cliped to the heatsink and the other lead clipped to the drain lead at the MOSFET body. MOSFET #1  MOSFET #2  Compound was applied between the MOSFETs and heatsink the same way heatsink compound is used. MOSFET #1 with compound  MOSFET #2 with compound  The MOSFETs are mounted with a 4/40 screw and a fiber washer. For better clamping and long term stability I think the use of belleville spring washer like this between the mounting screw and MOSFET body is worth looking into. The spring will keep the clamping force constant allowing for changes brought on by temperature. The belleville spring also applies the clamping force at the outer edge of the spring washer instead of in the center of the mounting bushing spreading the clamping force over a much larger area. With the issues of the China inverters having the habit of unexpected smoke events, it makes one wonder about the low clamping force non gas tight copper/tin to aluminum connections used in said inverters. The MOSFET to heatsink clamping force is nowhere as high as generated in the electrical cable clamps where the compound is recommended. Comments? Zathros |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2951 |

Your tests demonstrate the worthwhile advantage of a conductive compound between the surfaces. When measuring low resistances between different metals I have found it necessary to swap the probes to measure in both directions then take the average. The thermoelectric voltage produced at the junction can affect the readings a little. When bolting to aluminium the recommended method is a thick flat washer with extra large O.D. to spread the load and a cup washer to accommodate the different thermal expansion of the bolt and the aluminium. Cup washers are designed for use with aluminiun and preferred over spring washers. Aluminium will "cold flow" over time if the clamping force is too high. Spring washers are easily overtightened whereas a cup washer will begin to crush when the correct force is applied. You stop tightening as soon as the cup washer starts to deform. |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1180 |

Many mosfets make poor direct drain electrical connection due to the Drain flange being not perfectly flat; check with a metal ruler straight-edge. For direct connection, I generally rub the flange on a sheet of glass with 1000 grit emery paper and some kerosene as lubricant, doesn't take much. Your alloy heat-sink will oxidise in only a few minutes, thin smear of petroleum jelly on both surfaces will allow for a great connection, as the particles in any heat-sink compound can raise the resistance. Cup washers as Phil suggested are a great idea. Cheers Mike |

||||

| Zathros Newbie Joined: 20/09/2024 Location: United StatesPosts: 6 |

Seems that I've come across this before. Will check for it after the MOSFETs and heatsink are cleaned of compound and reassembled. Good to know. I had noted that the spring washers were speced to work at around .004" deflection. That is 20% of a single turn on the common 4/40 screw. Do you have a link showing cup washers? All I've come up in various web searches are the ornamental finishing washers Yes, I have done the MOSFET packages the same way. Also have dressed the heatsink mounting area with 1000 grit paper wrapped around a file with keroscene or IPA as lubricant. The aluminum wire compounds are loaded with zinc powder which is clamed to penetrate the aluminum oxide layer when clamped and decrease both electrical and thermal resistance. Also creates a gas tight connection, important for long term reliability. Zathros |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2951 |

They do appear to be hard to find now but this looks promising. https://www.bokers.com/washers/custom-washers/cup-washers/ |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1619 |

I have made my own cup washers when I have needed them, just drill a hole in some steel 0.5mm smaller than the washer and use a punch a tad bigger than the hole. Only one good tap is needed and the cup washer is made. Now with the subject of isolating the fets on a heatsink are the fets on the Madboard isolated or connected as I am closer to building this board that is one question I do need answered. Regards Bryan Edited 2025-09-05 16:00 by Bryan1 |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1214 |

Hi Bryan, The Fets on the Mad power board were not isolated from the heatsink's, but you can if you want to do a little modification, Will see if I can find your build thread and post there. Cheers Aaron Off The Grid |

||||

| analog8484 Senior Member Joined: 11/11/2021 Location: United StatesPosts: 183 |

Thanks for sharing the interesting test results. Did you also test with typical CPU heatsink compound? That should help but I think bar clamps that are wide enough to cover most of the MOSFET package and centered across the package would provide even more balanced pressure. |

||||

| Zathros Newbie Joined: 20/09/2024 Location: United StatesPosts: 6 |

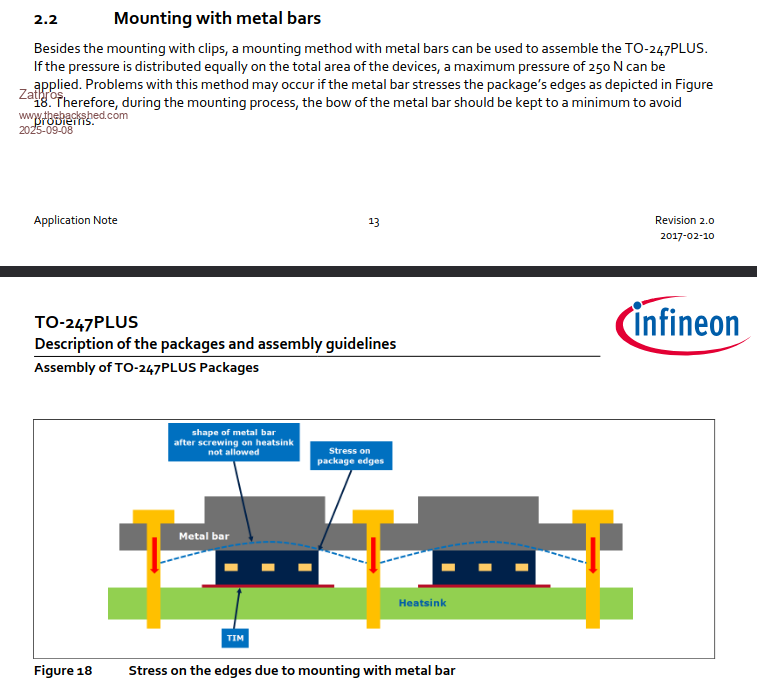

Your welcome. No, I did not test with regular heatsink compound. This test was concerned with improving the electrical as well as the thermal connection. Regular heatsink compound is filled with non conductive filler. Yes, bar clamps work great. Good choice while designing, but can be difficule to retrofit. Great information in the Infineon Application Note AN2017-01 Excerpt from AN2017-01:  For upgrading existing mountings I've chosen the following washers. They are compatable with 4/40 SAE and M3 metric screws- Flat washer to spread the compression load over the package. McMaster 92217A369 flat washer, ASME wide designation .125" x .438", .036" to .045" thickness McMaster 9712K53 Belleville washer, rated at 11 lbs (50 newtons) working load at .004" deflection and 17 lbs (75.6 newtons) compressed flat (.008" deflection) The forces provided by this belleville washer are in the middle of the exceptable pressure for the TO-247 package. Make sure that the belleville washer is in the working range of compression and not compressed flat. Gary Edited 2025-09-08 09:38 by Zathros |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |