|

|

Forum Index : Windmills : new chinese wind turbine blade mods

| Page 1 of 2 |

|||||

| Author | Message | ||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

has anybody done a "fishing line" bump mod to the blades on the "NEW" a chinese 300W mill?? http://jaycar.com.au/products_uploaded/productLarge_11259.jp g i modded the tips and sanded back to a knife edge but still would like to make a little quieter.... the fishing line mods that appear are for the old straight blades but the new chinese blades are much more curved,so i was wondering if the fishing line mod would still work? Cheers, ....Richard |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Richard i tried this on a 3.6m twisted low rpm prop (about 140 rpm cut in) and didnt notice any real difference in reduced noise ...at a higher cut it should be more effective i,ve seen it incorporated into new bergey blades , these have a very smooth surface finish which might work well with the ridge (you can just feel it running your finger nail across it ) also as well as reducing noise it might even improve the lift effiency of the back of the blade ..  .... (can of worms material .... (can of worms material  ) )niall |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

140 RPM, that`s fairly slow compared to mine i think i have noticed my mill is actually quieter when it gets up to speed and starts pumping amps.but just below this speed (cutin?) the blades are more noisy. just for the hell of it i will rig up some gafffer/plumber/100mph tape with some fishing line. will post the results, (no wind here at the moment of course....) what would/did you use in diamter on the fishing line i have some 2.8/3mm whipper snipper cord (rounded not star) i will give it a go...... |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi richard the line i tried was about .75mm , copying the fieldlines post ...

i was kindof going by the bergey blade i seen at eirbyte which had very fine ridge (at a guess it was about .2mm on a 1.5 m blade)..... surprisingly small my prop has a wider cord so i upped it a bit if you try a fine line its tricky to get a pronounced ridge when you tape it ...like the guy in the fieldlines post suggested you need to run your finger nail along the line sides to kind of lift it playing around with different thickness,s of line for a particular blade might be the only way to get some kind of result...i have lots of neibhours so noise mods are always worth trying for me

i think theres something on the forum previously but i could never find it niall |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

you say 0.2 or did you mean 2mm ?? and what size cord did you end up using? |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

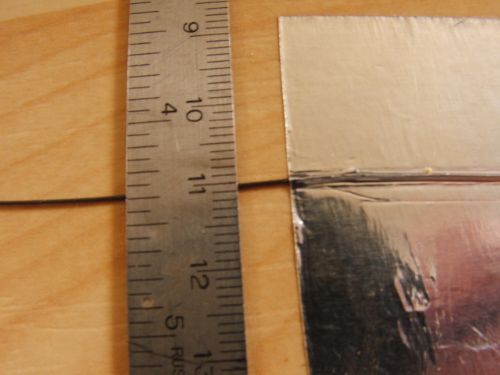

hi richard heres what i tried almost 1mm thick

the origional bergey ridge really is very small about .2mm it just looks like a slight manufacturing fault hope electronbaby doesent mind  heres his mod heres his mod

i used aluminum tape which sticks pretty well (to well as trying a slightly thicker line will be a pain in the  ) )

somewhere around 1mm might be a good starting point ...3mm sounds big though ps ..i,d like to see your blades but i cant paste your link and find the mill

niall |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

any body got an idea of cut in speed of these new 24 volt chinese mills? this is written on the jaycar web site, might help some to guess the cutin speed MG4532 - 300W 24VDC • Rated Power: 300W • Max Power: 500W • Output Voltage: 12Vdc or 24VDC • Start-up wind Speed: 2.5m/s • Rated Wind Speed: 12m/s • Max Wind Speed: 40m/s • Rotor Diameter: 1.5m • No of Blades: 3 • Blade Material: ABS • Recommended Tower Height: 6m • Shipping Cartons: 900x400x200 - 17kg total • Included: generator, blades, tail, hub, nose cone |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

ok mods done 3m tape and a 1.5mm "bump" we have zero wind here (BOM shows 0 kph)!! so hope tomoroow will be the day...forcast 35kph winds will updae once i get some results... |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

ok it works!! i used as a temp test/experiment some 1.5mm multi stranded electrical wire that is round and has a pvc covering. used some 90mm 3m tape to hold it in place will keep a eye on it, and if all is good i will super glue some fishing line to the blades... permanantly |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| greengoblin Newbie Joined: 03/03/2009 Location: AustraliaPosts: 14 |

Gday Richard, i have one of those mills and found it to be noisy also, it made a whistling noise at most speeds. i walked to my neighbors place, about .5kms away to see how intrusive it was and found it was actually worse there, one of those noises which really travel! I did the mod suggested on this site "How to improve those cheap chinese blades" and glued 1.6mm wipper snipper chord to them. The mill is now totally silent at all speeds, it worked very well! Just another tip, the bearings in this turbine started to get noisy after just one week so these were replaced at the same time, have had no problems since. Cheers Pete. |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

is your mill the new type as in the jaycar website 300w 24/12v twisted blades http://www.jaycar.com.au/products_uploaded/product_11259.jpg or the older straight bladed type? http://www.jaycar.com.au/products_uploaded/productLarge_1126 2.jpg do you have any photos? |

||||

| greengoblin Newbie Joined: 03/03/2009 Location: AustraliaPosts: 14 |

Me again Richard, Tip no. 2, when you buy sealed bearings, they come pre packed with grease however this grease is not much different to vaseline, bearings will last a lot longer if you flick out the seals and pack them with good quality high speed bearing grease, the seals will click back in ok.......Pete |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

hi Pete, you have missed this from the last page RE: bearings, i had the big (3 blade straight fibreglass) unit up for years (but with a much smaller set of blades) and never had a bearing problem.... but not sure what mill you currently refering to with the w/snipper cord mod? new or old type? is your mill the new type as in the jaycar website 300w 24/12v twisted blades http://www.jaycar.com.au/products_uploaded/product_11259.jpg or the older straight bladed type? http://www.jaycar.com.au/products_uploaded/productLarge_1126 2.jpg do you have any photos? |

||||

| greengoblin Newbie Joined: 03/03/2009 Location: AustraliaPosts: 14 |

Sorry Richard, i assumed mine would be the new type as i only bought it last nov. but it has straight blades so we are running on different tracks. Am a novice with these bloody computers so wouldnt know how to put a picture on here even if i had one! |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

look like this?

or  |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi greengoblin, good to hear the blade mod has worked for you too. Its a easy fix to a common problem. I see Jaycar no longer sell that windmill with its China made mast, quote "The original wind generators came with crude mounting hardware. We were not happy with this....." and they go on say they no longer include the mast and suggest you buy poles and rigging from a hardware store. It's good to see them take a responsible approach. Now if we can just get them to include a link to thebackshed's blade mod page

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| sPuDd Senior Member Joined: 10/07/2007 Location: AustraliaPosts: 251 |

I like the way you think :) sPuDd.. It should work ...in theory |

||||

| rgormley Senior Member Joined: 22/02/2006 Location: AustraliaPosts: 245 |

yahoo!! we have some nice winds at last...

(24volt mill) The temp blade mods (electrical wire and wide gaffer tape) are working well best i have seen the mill do is a burst upto 15 amps but the batts are around 24v anyway. winds are around 20-22 kph gusting to 41kph unfortunatly the south /south/west winds are very broken here so it keeps turning all over the place, but when it sits into the wind it`s happy and neighbourly quiet.. the northerlys are the beat for me.. have to wait... Cheers, Richard! |

||||

| greengoblin Newbie Joined: 03/03/2009 Location: AustraliaPosts: 14 |

Gday Richard, sorry i never got back to you, my mill is the one in the first picture with the barn. Thanks Glen, the mod to the blades works great, dont know why or how, but dont have to! Yep those masts, especially the mounting plate leave a lot to be desired....cheers Pete. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |