|

|

Forum Index : Windmills : Building a Darrieus H rotor

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

I have one 3m length of the sample PVC blade left, and I'm thinking of cutting it into 3 and making a 1m high H rotor.

I plan to use 1 inch timber dowel up the middle of the extrusion instead of the steel tube cause I dont need to hold the blade from one end, I can screw it together with timber screws, and its lighter. A Darrieus works best with a profile that is symetrical on the inside and outside of the swept path/diameter. The extruded blades have a curve, so I worked out the ideal diameter that would pass through the center of the blade profile. This path is shown in blue, and you can see how A = B along the length of the blades chord. This gave a diameter of 580mm.

If I go bigger in diameter, I gain power. I do loose RPM, but will ignore that for this exercise. I wonder how much I can increase the diameter before I upset the air flow and get a decrease in power. Below is at 800mm.

Still looks ok. At 1200, below, I think I may be pushing my luck. I'm also loosing solidity by increasing the diameter.

Any comments? I've never played with a Darrieus before so this should be a fun project. I'm aware I need to spin it up before it will start to power itself, I'll use a pull cord to test at first, and later try a smaller Savonius made from PVC pipe. I have a servo motor as the load, this is too small to drive a F&P. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Hi Gizmo, What is the blade chord you have?Those blades should easily selfstart with the right solidity.You may want to keep it pretty narrow with so few blades.I think .3 is a good solidity for the giro. Thats just me though. Have fun and nice to see  |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hey vawtman The chord is 160mm. If I use a 600mm diameter with 3 blades, to work out the solidity, total blade chord of 480mm ( 160 X 3 ), divided by the circumference ( Pi X 600 ), gives approx 0.25 Is that right? Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

you mm guys kill me

Yep and should selfstart and run great at that. Giver a go

|

||||

DaViD Senior Member Joined: 14/01/2009 Location: United StatesPosts: 120 |

Hi Glenn, What kind of r.p.m. are you looking for with this motor? If your not living on the edge your taking up to much space! |

||||

DaViD Senior Member Joined: 14/01/2009 Location: United StatesPosts: 120 |

Just a quick question, at what point does suction side flow start to creat a loss of efficiency? If your not living on the edge your taking up to much space! |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Hi David, There comes a point where the blades go into stall.By stall they don't stop spinning just maintain that speed and no faster.I think it's a good thing. I built a small giro early on and at 30mph winds would spin at 120rpms and at 60mph winds still only spun at 120rpms.However the tower bent

The hawts run at such low solidity(high tsr) that the blades can fly for football feilds when out of control

It's funny when i first started everything was the darrieus bein the nasty boy.Sure the skinny bladed eggbeaters would be nasty if gone amuck. |

||||

DaViD Senior Member Joined: 14/01/2009 Location: United StatesPosts: 120 |

Thanks Vawtman, I'm trying to learn a little about the vawts. Am I correct in my thinking that there is a suction on the inner side of the blades that could cause performance issues or am I completely wrong? Rember just trying to learn a thing or two  If your not living on the edge your taking up to much space! |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

By suction do you mean drag? If so yes all airfoils have it.You can't suck the wind into a wind turbine like a centrifugal pump pumps water if that's the thought. It's actually pretty cool on the inside all you feel is tiny pulses when the turbine's up to speed.Pretty cool and hope someone else in this world experiences it sometime  Maybe OZ did with his ground level hawt. Maybe OZ did with his ground level hawt.

Where there's gains there's also losses it's the law of the land.  |

||||

DaViD Senior Member Joined: 14/01/2009 Location: United StatesPosts: 120 |

I'm not saying anymore so I don't sound really stupid   If your not living on the edge your taking up to much space! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

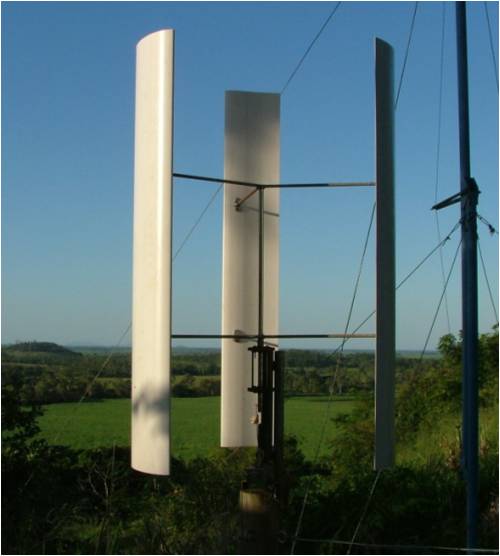

I finished it off today.

No load yet, and no wind either

Will post another update when I see some wind. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Just a thought Gizmo. How much flex is there when you push on a blade by hand? The rods appear to be thin. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Just too too cool  ..... you will start a whole new VAWT thing I'm sure. ..... you will start a whole new VAWT thing I'm sure.

......oztules Village idiot...or... just another hack out of his depth |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hey Gordon. I was thinking the same, buts its actually a lot stronger that I though it would be. The center shaft is 12mm and the rods are 8mm steel. Its only 1000mm high by 600mm wide, so not a lot of wind frontage. It runs on a couple of bearings. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| justmick Newbie Joined: 19/04/2009 Location: AustraliaPosts: 2 |

Love the vertical design always prefered that for suburbia. A question if I may if building one to plug into the grid and not stand alone to a battery set up, do you need a certain size/type of stator or will any still do as long as you get the right inverter to match. Would it be better to buy these parts together as a set. Mick |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Mick The small backyard VAWT's ( or even small HAWT's ) dont make much power. They are good for powering garden lights or water features, thats sort of thing. Plus they are fun to make and fun to watch. If you want to feed power back into the grid or make a dent in your power bill, you need to go big. Some of the forum members here have done just that, they have big turbines on tall masts with good wind, and they feed the power back into the grid. Anything under 2 meters diameter isn't going to reduce your power bill unless you live in a VERY windy location. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| justmick Newbie Joined: 19/04/2009 Location: AustraliaPosts: 2 |

thanks Gizmo Seen some impresive VAWT`s around. The Backshed.com had a link to a japanese company making comercial towers over 7 metres putting out 1kw but they look expensive. Heard you guys talking here about spending less than $100.00, thought if I could get the right parts for the right price I could as you say make a dent in my power bill, but not really keen to go that big now I`m off the farm Sounds like I`ll just stick to my little set up for the aquaponics........ for now. |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Hey Glen Just curious and wondering  |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Sorry vawtman, no wind. Been still for a couple of days, even the big windmill hasn't moved. Lots of sun though  , someone needs to invent a solar power windmill. , someone needs to invent a solar power windmill. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| murraymint Newbie Joined: 22/04/2009 Location: United KingdomPosts: 1 |

Hi Guys, first post. I just love this site and it's full of really useful stuff. I have a question regarding the shape and profile of the blades, Is it best to use a symmetrical or an asymmetrical aerofoil or will it not make a big difference. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |