|

|

Forum Index : Windmills : downwind furling machine

| Page 1 of 3 |

|||||

| Author | Message | ||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

this seemed to be hidden in the dark creepy vaults of fieldlines at least for me anyway ....

by micks ..........ergo the angle grinders being warmed up for the old mill... its downwind.... its got a minimal tail... and it furls...... cant help wondering if a car shock absorber could be used to dampen the return movement ? edit...seems like when it is trimmed out using the counterbalance pole this isnt a big issue http://www.fieldlines.com/story/2007/2/11/92339/2971 niall |

||||

marcwolf Senior Member Joined: 08/06/2009 Location: AustraliaPosts: 119 |

I have seen this as well and it looks to be a good solution. Only minor tings is that your windmill looks like i is running in reverse :> Also be very easy to change just by enlarging or reducing the furling sail. This could easily be done re some PVC plates with expansion slides. Dave Coding Coding Coding.. Keep those keyboards coding.. RAW CODE!!!!! |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Dave its pretty interesting ...the furling action seems to be in one plane ..unlike the normal ..tail sideways and up.. at the same time .. kudos to that man ...  niall |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Yes I'm getting the itch to make one of these too. I just can't seem to get the gravity furling to be as good as I want it.... yes it works fine... but I think there has to be a better way. .........oztules Village idiot...or... just another hack out of his depth |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

I have a pic at home of a furling system for downwind turbines, I'll uplad it tonight. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

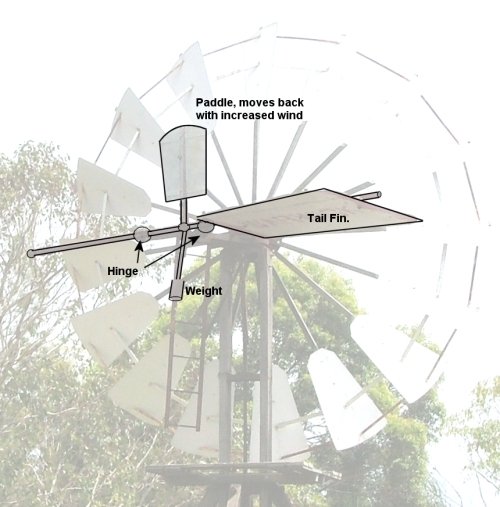

This is the furling system I saw on a old water pumping windmill. Hopefully the pictures explain how it works.

The turbine blades are angled back to give better wind following. A horizontal shaft is held out in front of the windmill by a couple of hinges( bearings ). At one end of the shaft is a tail fin. Mounted off the middle of the shaft is a paddle and weight. The other end of the shaft is there as a counter weight to the tail, to keep it all in balance for longer hinge life. In normal operation, the weight ( opposite the paddle ), is held down by gravity. This in turn keeps the paddle vertical, facing the wind, and the tail fin horizontal. As the tail is horizontal, it catches no wind. As the wind increases, the paddle is pushed back, acting against the weight. This turns the tail fin up from the horizontal, catching wind, and turning the windmill out of the wind. As the windmill turns out of the wind, a new balance is found as the wind pressure decreases against the paddle. Is a simple system once you get a grip of how it works. The weight is adjustable, making it easy to change the furling characteristic of the windmill. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Well, I didn't see that one coming

Simple solution... not one I would have dreamed up, but looks pretty useful anyway. There's just so many ways of doing the same thing .. it's amazing. ...........oztules Village idiot...or... just another hack out of his depth |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

very nice .. a reverse tail.... like a sort of trim tab .....tilted back blades too ...

i,ve taken down my mill ,dissambled and weighed it for the first time axial alt, blades , mount and hub come in about 50 kg .....so its off to the scrapyard next to find a butch pivot of some kind to hang it on and try to get a feel of what,l need to happen next .......... lots to think about ...  niall |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

after getting the grinder out and some head scratching i,ve decided to try to copy this type of downwind furling idea http://www.fieldlines.com/story/2004/1/10/164855/803 , the mill becomes a kind of pendulum and should try to furl vertically , no tail then..... but lots of unknowns...

the pivot is make up of two pillow bearings and a one inch shaft ..all a bit butch then but works smoothly with no play

i doubt the tower will take too kindly to it...  .., it doesent weigh much more than the origional upwind but it will be kind of .....hanging its bits out there ... .., it doesent weigh much more than the origional upwind but it will be kind of .....hanging its bits out there ...

i,ll try to put a thrust bearing at the top of the yaw pipe , just to see if it suits a downwind machine better ( i know that can cause issues with upwind ) dunno how this will work as it,ll be hard to keep the grease in and the crud out but should be worth a try

you know when you,ve got to much time on your hands when you start ............ niall |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

Niall, that's an interesting way you have to make a sleave for the bearing to ride in. I'll have to remember that. You might find a cup or shallow bowl to cover it if you are concerned with crud infiltrating the bearing. This is an interesting project. I think it will work out well. Keep up the good work. philb |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

Hi philb mmmm .... now after thinking about a cup seal i figure theres one or two ways to fit a homemade one ....  .. alot will depend on how much clearance there is and how central the bearing is ...should be fun .. alot will depend on how much clearance there is and how central the bearing is ...should be fun niall |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Niall, I'm watching this with much interest. When i get some time I shall try a a similar setup. .............oztules Village idiot...or... just another hack out of his depth |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

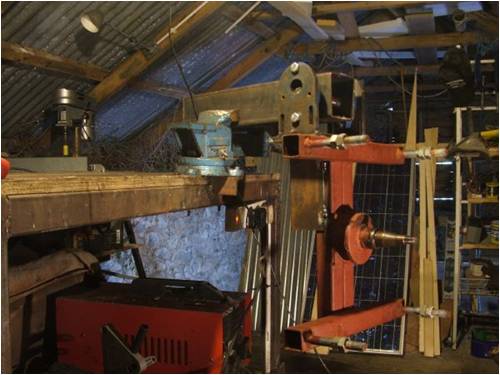

first test fit on the mast ...strange fish indeed...

the alt (at least this one) seems to take a fair amount of force to rotate it on the pivot...the pivot is smooth enough , but the alt is heavy ..hopefully it,ll get a run next week ... i,m probabely underestimating what a high wind can shift anyway ... ..worryingly i,m beginning to day dream about pre-loading the furl with an adjustable spring ...  ..i tried to read up on static balancing but the head began to hurt and in the end i gave up ..i tried to read up on static balancing but the head began to hurt and in the end i gave up

ps ...Philb,s dust cap ..a light hacksaw cut around the washer and the milk bottle top clicked in  ..... .....

....

niall |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

niall, looks like you are only a few steps away from having the unit in the air! I'm looking forward to seeing it fly. It has great potential.

If you are concerned about the late furling, could you add more weight to the arm on top of the unit? A pulsation dampner came to mind instead of a attaching a spring to the pivot. This might keep the unit from slamming the tower in gusty winds, while allowing it to furl easily. On second thought, it might take a big gust to do this since your generator is away from the tower. I like the way your yaw bearing fits into the mast also. That makes it easy to service or replace. In my area, I would have had to make the dust cover extend down a bit (2 cm) more because of blowing dust and rain making a grit grinding compound. Have Fun philb |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Will be following your project with interest. My very first axial flux (miniature one) was supposed to become a downwind turbine with upward furling, until plans changed (a few times  ). ).

Are you familiar with WindstuffEd's downwind turbine? http://www.windstuffnow.com/main/test_page.htm I agree with Philb, a damper would probably need to be included. Not to prevent it from slamming into the stops, but to prevent it from oscillating: what you have now is a mass-spring system that, once excited, will oscillate back and forth around its equilibrium state. The oscillations will slowly dampen (due to natural damping, because of friction). The process of damping could (should?) be accelerated by means of a damper, in essence turning it into mass-spring-damper system. Ideally, you'd have to tune the damper to be critically damped (not over- or undercritically): http://en.wikipedia.org/wiki/Damped_spring-mass_system and http://en.wikipedia.org/wiki/Harmonic_oscillator But time will tell whether you'll really need this damper or can rely on natural damping. Looking forward to seeing test results of your contraption. Peter. |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

first off thanks for the suggestions and links ......tunnel vision is a bad thing ...

..Peter i did come across that windstuff machine.. ed and i think its kevin on the fieldlines post had interesting feedback about downwind machine traits just adding a spring now sounds a bit simplistic .. philb adding a counter weight is i think is very doable ..the pivot is pretty strong and the weight might even be set up on the upwind side to give it a bit of leverage (still thinking about this ) ..the fly in the ointment might be how my tower behaves (i.e. doesent start to oscillate itself ......  ..)..tower permitting this could be the way to go to effect the furl ..)..tower permitting this could be the way to go to effect the furl

i origionaly only thought of the dampener with regard to the stops ...  ..the plot thickens then ..the plot thickens then

this next bit was going to go in other stuff but it might have some relevance here ...in a less lucid moment i thought about adding an active hydraulic ram to furl the mill

its an ordinary power steering pump and single acting ram out of the scrapyard , the pump is hooked up to a 36v scotter motor (lately these pumps are appearing with their own 12v motor built in ) i set it up with a lever and pivot and sat on the other end thinking this this would keep it retracted ..even with a little old 12v strimmer battery it had other ideas and proceeded to gently lift my 80kg,s towards the shed roof...

all power hydraulics come with a health warning so i left it to one side niall |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

progress on the contraption .....has been a bit slow ...stuff is almost fitting backways ......  .....but, usually dosent... .....but, usually dosent...

the springs i,m not sure about but.... as with the suggestions theres only one way to find out...and then think again

the springs have no leverage in the normal position...once (if it can ) the alt does try to furl they might sort of come into play ..(the cattle trailer approach to influencing furling then)..... plenty of warts are waiting in the long grass ...

updated a bit ....finally up ..but not much wind...  niall |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi niall, you mention a fair amouint of torque to rotate the machine around the top of the pole, even with a tapered roller. You could consider adding a counterweight to the upwind side of the assembly. This will reduce the twisting moment on the tapered roller bearing. The weight will be inversely proportional to the distance it is placed from the vertical pivot axix. Good luck. Gordon. become more energy aware |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Gordon your right about the yaw bearing ...its smoother than pipe but not a true thrust bearing set up ..this looks like it could be a bit of an issue (its hard to tell yet but i suspect probabely a big one ) with this setup tracking light winds......

now its up.... the mast at least seems happy enough with it ...(the upper stays were able to go a good bit higher)..so any counterweight is fair game niall |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Boy, this post got really long, fast! This approach resembles something I did many years ago; I built a "tilting" tower. I put up a post somewhere here on the 4m telling how to build a it. To be brief, my tower hinged on an axle and was "pinned" with another axle. When the winds got out of hand, I merely yanked the lower axle and lowered the tower. I once saw another fellow's approach and that was a hinged tower and a counter-weight that caused the windmill (down-wind design) to tilt back and spill the wind off the tops of the blades, thus limiting their maximum speed. His entire tower was hinged and swung around in the changing breeze. When the wind speed got high, the tower bent back, spilling the wind off the rotating blades of the windmill. Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Page 1 of 3 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |