|

|

Forum Index : Windmills : Modified Chinese blades under test.

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Remember those Chinese blades I modified a few weeks back? Well I've sent them off to David Warren in Townsville for testing. David has the perfect set up to test my blades: lots of wind; a 200 watt Chineese windmill he been running for some time; and a F&P windmill ready to be put into service. So i packed up the modified blades and my hub to suit the F&P shaft. David has mounted the blades onto his Chinese windmill, and here are his early results in his words..... "Put them on my Chinese hub and rebalanced. They have been up for 2 hours now and I can already see some difference. 1. slightly negative. they take more wind to start up. 2. up to 200 rpm (visual again) there virtually no sound…….a definite improvement 3. from 200 to 600 it is also quieter probably about 20% in that range 4. however there is still a high pitched whistle that I can hear thru my office window at 400-600 rpm (probably 45 metres) 5. this whistle could also be from the pm motor its self……….did you get any whistle on your F&P? 6. I also believe that mill performs better at the higher speeds but with out a logger its early days " I've since had another email from David with more results, and I'll post that in the next day, just waiting on some photos. But it looks like the modification has reduced noise at low speed, and gives a power increase at high speed. Unfortunately there is still a lot of noise at high speed, but this may in fact be from the alternator itself. Does anyone else with those Chinese windmills get a lot of alternator noise? Keep ya's posted. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| RossW Guru Joined: 25/02/2006 Location: AustraliaPosts: 495 |

Mine is the 1000 watt version, not the 200, but its alternator makes very little noise. I can hear it (mostly at low RPM) in the mast itself. Although the mill shows no sign of cogging, that's what it *sounds* like. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

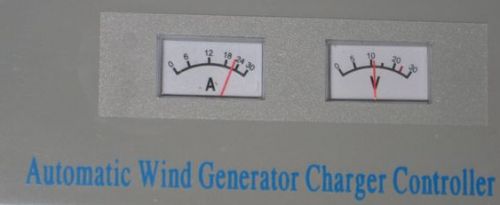

OK here's the latest, plus some photos. Again, in Davids words.... "Hi Glenn, I will just ramble on and list it as it comes into my head. Observations to date: Your blades have been up 6 days now Noise levels are a little high. at higher revs the whistle gets higher pitched and can be heard many many metres away Still some of the whine is the turbine as I don’t get it on the F & P with Chinese blades. The reshaping definitely requires a much higher starting speed. However the start up speed here is still acceptable for me. We get wind virtually every day from 10 am till 6 pm and quite gusty. With the original standard Chinese blades and the Chinese controller I have seen the amps stay between 4-8 and peak burst up to 18-20 amps Now for the good news: After about 10 in the morning the output with your blades shows 6-12 amp and quite often bursts up to 24 and I have even seen the amps go of the scale at 30 amps………The high end improvement is dramatic!!!!!!!!!!!!! (if only we could get the noise down) This makes my 200w mill a great little beast. Have ordered from Trev a tristar 60 amp controller with display and data logging. massive overkill but what hell its cheaper than a set of golf clubs. That should be here by the end of the week. So I can continue with the f & P s. Just as you said one bar the hub extender needed packing (about 30 mm out at the tip…. When I finish I will mark that one on the hub and maybe you can give it a tweak. With standard Chinese blades at 2.5 m diameter and a 5 degree angle of attack the start up is very very poor (decogged 8sp star 12volt) However if you increase it to 10-12 degrees the start up is reasonable but the output is poor as I can’t seem to get enough speed for a good output I have to say so far that the Chinese mill works much better than an f & P (going by the number of people who rave over them I must be doing something wrong) Next month will probably convert to 7 pole cogless and see if I can get these to go. If you wish to put anything about this testing in you diary forum can you put in my own email warrendj@bigpond.net.au and say if there is anybody in Townsville who would like to see your blades and hub they can contact me and am happy to have them come round" So there you go. As David said, if anyone is in the Townsville area they can drop him an email to plan a visit. Looks like the blade modification only helped noise at low RPM, but has given some real gain at high RPM. Davids 200 watt windmill is making over 360 watts.

The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| petanque don Senior Member Joined: 02/08/2006 Location: AustraliaPosts: 212 |

While my experiences are related to full size gliders. Has any body experimented with wing tips on wind mills? There are pictures of a glider with wing tips at http://www.alexander-schleicher.de/englisch/produkte/ash25/e _ash25_main.htm the theory that the low pressure area at the top of the wing and the higher pressure area at the bottom of the wing are better separated this causes an increase in efficiency and a reduction in noise. The maximum speed of this glider is 280 Km/hr how this compares with the speed of the tip of a windmill blade I am uncertain. The state government in SA have funded some small wind turbines that seem to have a rotor (fan?) with 5 blades and a ring connecting the ends of the blades I have not been close enough to one of these turbines to asses how noisy they are. http://www.alexander-schleicher.de/englisch/produkte/ash25/e _ash25_main.htm |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

No concerted efforts experimenting on tip design yet. Most efforts are aimed at making blades with minimal resources at a low price. However with emergence of the cheep but noisy Chinese blades, a couple of ideas have been mentioned to reduce noise levels. I understand the glider tip as viewed in the photo is primarily an aid to stability rather than aimed at noise reduction. Though increased efficiency also occurs it must therefore reduce any noise also. Perhaps the vortex at the tip can be reduced in a more structurally simpler way? To date, rounded tapered tips like this;

and leading edge rounded off;

have been suggested. Even a cigar shaped tip. But to date, no trials and no comparisons. David or Glenn, What method is used on your blades under test above? In the photo they still appear square tipped? I'm fitting Chinese blades now but haven't decided which way to go. Am inclined toward the model helicopter style first then changing to fully rounded and tapered if not happy with noise levels. Decisions....decisions... was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Gill, I mentioned this in an earlier post, regarding 90 degree tips, a fellow from westwind told me to put these on to reduce noise at high speed. I never tried it but it's probably worth a go. I presume the theory is to reduce wind spilling off the tip, thus keeping it and the force on the blade, dunno never tried it. Central Victorian highlands |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

I did round the leading edge of the blades. The problem with blade noise is its very hard to find the cause, sometimes is just a simple change in profile that will either fix the problem or make it worse. This photo was taken after the first coat of pain and sanding with wet & dry, You can see how I rounted the tips.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

MMmmmmm. Sorry Highlander, had forgotten that one. Probably because I dismissed it as not really viable. As I understand it, The wing in a upward "V" shape and all it's variants, and this includes the up turned wing tip, promotes greater stability. Examples can be seen in the glider pics Don linked us to. See how the wings flex excessively upward, also the upturned wing tips. In the "W" profile of the wartime Stuka dive bomber, and, in nature, with the pintail(wing tip) feathers of high soaring eagles we see this . Also the winged keel of Aus II. I understand that as the craft rolls, the lower wing becomes more horizontal and the upper wing more vertical thus gaining more lift on the wing that has dropped and less on upper wing hence righting itself automatically. In fitting this more vertical wing section to the tip,they have stabilised that part of the wing which is prone to flapping about, and as a by product, are given a tip that does not incur the same lift pressures as a horizontally terminated wing. Hence less vortex. And vortex = noise. In addition to all the methods mentioned so far, we can add a vertical plate on the wing tip. Some early planes used this, and it acts the same way the Cigar shape does in that it creates to long a path for the pressures to equalise around. For example Don's mention of SA turbine. Well fellas thats the way i understand it. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Thanks Glenn, Couldn't see that in the test photo. There's only one thing for it Glenn, you're going to have to build us a huge wind tunnel, with acoustic monitoring built in. Yehhh!  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Prof Newbie Joined: 01/12/2005 Location: AustraliaPosts: 33 |

?? " after the first coat of pain and sanding with wet & dry, You can see how I rounted the tips." Hi Gizmo, As usual I can see your standard "blue" paint work but did you start off with some "red" ??

Will try to organised a visit to David to see the blades in action. Prof. I know boats!! |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Glenn, Just looking at the trailing edge, I see that it is not as fine as I would like. Possible turbulence area??? As a test I'm thinking two strips of say 1" masking tape, one top, one bottom, half inch on the prop other half stuck together. Simple enough and non destructive. Then later I'd try much wider tape closer in to the hub due to the ever increasing angle of attack and it's greater turbulence there. Just a thought.

was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| windman Newbie Joined: 02/12/2006 Location: Posts: 19 |

this is one of the machines installed by the SA Gov grid connected . I have been told that the performance has not been good but quiet |

||||

| petanque don Senior Member Joined: 02/08/2006 Location: AustraliaPosts: 212 |

Looks like you drive along Salisbury highway near main north road as well. It doesn’t spin as quickly as other turbines I have seen I have never made time to stop and look at the windmill closely. However it is in a brilliant position as far as the general public seeing a small wind turbine and becoming used to the idea. In the cigar shaped wing tips you may find the picture of a Blanik interesting (I learnt to fly on one of these) Blanik There are a variety of styles of glider wing tips if they are worth copying I don’t know |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Have posted a link on Fieldlines once showing a large mill with those Rutan/Boeing vertical wing tips on the three blades. Will post it again if i find it again! Seems like the boffins also seem to instal them on the huge Megawatt mills and they should know what they are doing but for us DIY persons it would be a bit too hard. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| windstuffnow Newbie Joined: 30/06/2006 Location: United StatesPosts: 31 |

Just out of curiosity, where are you finding these blades? What does the trailing edge look like? Is it blunt, rounded, or come to a point? If thier blunt or rounded and/or the trailing edge is wider (thicker) than 1/16" ( 1.5 mm by my converter ) they will typically make quite a bit of wind noise. Also, I've seen a few where the trailing edge comes to a sharp point that will make some noise as well. Scraping a thin flat edge will quiet them down. Windstuff Ed |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

It's good to see all these diferent ideas especially with an accompanying picture if possible.

With the diverse variety of materials and profiles we try as a DIYer it's handy to have an arsenal of remedies to shoot down these problems.  was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

G'day Ed, I've put the micrometer on my set and they are smooth and rounded but @ 3.3mm Availability is through local sources: Foundry & Fiberglasss and eBay. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| jimovonz Newbie Joined: 09/04/2007 Location: Posts: 7 |

I did similar mods to some blades last year - some of which are visible/discussed here: Fieldlines link I have noticed a definate improvement in output and am working on getting some figures (unmodified vs modified) I wouldn't say mine are without noise but they are dramatically quiter than the unmodified blades and don't 'whistle'. I have had one turbine mounted on a fence approx 15m from the house and it has never been a noise issue (exposed site with plenty of wind). The turbine runs much faster which I think better suits the under spec'd alt. Logically you would think that faster blades come at the expense of harder startup but it hasn't been an issue for me |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Hey Glen, I noticed this on egay, the new chinese blades are aluminium.

They also said this "The 200w Aero now features aluminium blades (with curved ends for improved efficiency)" It's a bit hard to see in the photo, but it looks like they still have no twist. Did the fibregass ones have that ridge on the leading edge?  Central Victorian highlands |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Thats interresting, I wonder if they are available to purchase separately? A good vice, set of vice grips and a bit of a heave hoe and you could add your own twist. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |