|

|

Forum Index : Windmills : Iím looking for solutions for hub

| Page 1 of 2 |

|||||

| Author | Message | ||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Happy New Year from frozen Romania!

Frozen wood.

Also my windows, and one of my apples. Now, pictures with my fountain.

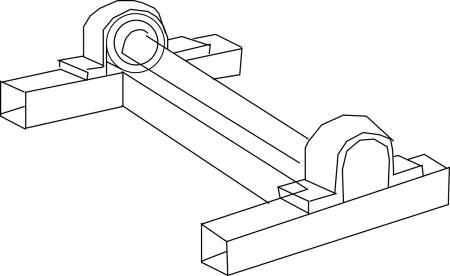

I think I will use this "procedure" to hold my bearings in position (for windmill). What do you think, guys? Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1650 |

Hiya Vasi, Eh mate thats a good idea for holding the bearings and there's only one thing that worries me with it, the bearings are open and any dirt can enter the bearings etc. Much better if you can get hold of some sealed bearings then you should see a long life out of them. Cheers Bryan  |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hi Bryan, I searched around (all markets from my town) for hubs like ones from Glenn web page but no success. So, I don't have other choices. I hope this will work. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1650 |

Hiya Vasi, A simple work around would be to make some shields on both sides of the bearing mount. Simply push some grease thru 1 side untill you see it come out the other side all even then put the covers on to stop any grit or dirt getting in and it should work for years. Cheers Bryan  |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Thanks Bryan, Maybe tomorrow I will make first sketch ... I will use sealed bearings from KiwiJohn. But we can find sealed bearings, hubs are the big problem. Here I get stuck . I saw you used the hub from washing machine, how it works? You can trust it will resist? Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

I'm thinking to this:  Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Hi Vasi I fear that your scheme would make it difficult to accurately mount the stator concentric with the shaft. I made a hub in a piece of water pipe and described what I did at http://www.thebackshed.com/windmill/forum1/forum_posts.asp?T ID=77&KW=resin |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

Bloody Hell it's 43 celcius here. Hey Vasi you could use these

I'm looking forward to your progress  Central Victorian highlands |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Vasi, now that looks cold! I agree with Bryan, make up a shield to cover the bearing and pump it full of grease. The shield will keep out most dirt, and so long as you can stop water sitting in the bearings, they should last years. You may just need to pump in some more grease every 6 months or so. And like John said, you need to make sute the hub is aligned perfectly center with the stator, you only have 0.5mm clearence to play with. 43c, man thats hot Bryan. Looks like all of southern Australia is copping the heat. I saw on the weather report last night it was actually hotter in Hobart than up here in the north Queensland tropics! That will teach my relatives who moved down there to get away from the heat

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

OK, I went downstairs and took some pictures! I found a piece of thick wall steel water pipe that the bearings are a close fit, in this case I had to wrap one layer cut from a tin can to make a tight fit but it is pretty snug in there and note I push it in about 3 mm below the end of the pipe. Now the stator, I should have cleaned it up a bit more but I was born lazy. I have used masking tape to block the holes in the stator and wrap around the lugs on this side of the stator. Next step is to place stator in the rotor and to push pieces of plastic or card in the pole gaps to ensure the stator is accurately centred. Then I put the shaft with its bearing in the tube into position on top of the stator. Because I pushed the bearing in that extra little bit the tube fits over the small ridge on the stator. The shaft is pushed through and into the rotor. In theory everything is now centred! Next comes the interesting bit where I should mix up some resin and pour it into the gap around the end of the bearing pipe and up to the top of the little dam made by that masking tape. Here is what it should look like when finished! Notice that I have used hose clips around the lugs of the stator as the resin does not stick to the stator which I think is a good thing as it enables me to change the stator easily. (Dont be distracted by the cut-away stator, thats part of another story! |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Thanks for support guys! Is very cold here, now my girls are wakeup and is cold in our room and must go outside to take woods for fire. Last night the stove was very hot but now is almost cold because outside is very cold. So, after this post I will make another fire (and maybe some sweet boiling wine) . Yes, Bryan you have right, I will use grease a lot. John and Glenn, I forgot about stator alignment  . .

Highlander, I will try to get some hubs like in photo (the bigger one) but is about a far away town... maybe for axial design. John, your photos are very helpful. Thank you again. [quote=KiwiJohn] Dont be distracted by the cut-away stator, thats part of another story! [/quote] Radio story?

Glenn, I think is good to move that topic of KiwiJohn to other stuff? Here is 8:46am and in Australia I think is 15:46 ... not much left from the old year

Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Hi Vasi It is 2015 on Monday here! Yes Vasi, the cut down stator is for the 50 watt 'pedal wireless'! I think my hub design is OK though anyone who uses it may want to make some improvements. Glenn, please feel free to move as you see fit! |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi Vasi And others Why are we not recommending the use of the FP hub or bearing holder I use them all time. I looked back and see one was sent. Herb |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

That's right we did. Vasi the white plastic thing the shaft went through that came with the box is the centre of the washing machine, inside it has an aluminium area which is quite strong. If you use a power file (or an angle grinder carefully) you can shape it to fit in some rhs steel then just weld it to whatever you want.

be carefull with the end which has the 4 threaded holes when you're reshaping, don't forget to use the metal disc's on each side of the stator.  Central Victorian highlands |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Happy New Year ,friends,, I used the nylon F&P hub ,rough cut with a sabre saw, then fine trim with a sharp spokeshave. fits perfectly in, ( I think ), 3 inch or 75mm pipe,have to drift it in with a soft hammer. Then a few pop rivets to stop it wandering . The steel pipe can first have little pieces of angle or lugs welded to it ,,so you can bolt the whole hub down on your platform-pic of it somewhere in my irc album. Hope this helps Bruce Bushboy |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Not all of us were smart enough to salvage the F&P bearing holders and I certainly have more rotors and stators than bearing holders! We only sent one bearing holder to Vasi and he did ask for hub ideas! So there are some choices, if you have an F&P bearing holder tube use it, if you have machine tools make something 'flash' if you are inclined. If you are like me and your shed is filled with family heirloom hand tools (rusty, blunt, busted or all three) then I have shown a way even you can make a hub and stator support. Happy New Year to you all! |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

I am not sure how many of those plates, if any, got sent to Vasi as I had almost none of them. |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

Hi all, I am a rich man with such a friends! So many solutions. Yes, I asked for solutions and also asked Bryan about using washing machine hub (I saw his work but I wanted more details about how he mounted that hub on the mast): [quote=vasi]I saw you used the hub from washing machine, how it works? You can trust it will resist? [/quote] And is about this picture:

The second picture is used to show that Bryan used the nylon hub in final montage. I wanted also something different because I not trusted that nylon hub and had no good solutions for masthead (I have now  ). ).

[quote=KiwiJohn]If you are like me and your shed is filled with family heirloom hand tools (rusty, blunt, busted or all three) then I have shown a way even you can make a hub and stator support. [/quote] I have one nylon hub and two F&P's, so one solution so far is from KiwiJohn and another one is from Highlander and Bruce. Bruce, your nice work is too professional for me and my possibilities (I saw your workshop and your tools). Highlander, what dimensions have that pipe? Thank you Herb for your intervention. Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

G'day Vasi, the bit of square steel is 60mm across inside, when you reshape the plastic you'll need to take of a little aluminium as well. Make it a tight fit and belt it on with a hammer. Just be really carefull not to damage the 4 screw mounts otherwise the stator won't go on square.

You can put a few screws through the side to make sure they won't drift apart. Central Victorian highlands |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |