|

|

Forum Index : Windmills : downwind furling machine

| Author | Message | ||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

interesting morning... it was pretty breezy so it let it run a while , as i was standing under it a few gusts hit it and it suddenly furled up ...almost horizontal ...scared the absolute wits out of me very surreal ...if you had a joint and watched it i doubt youd ever recover the action seemed pretty smooth ..its hard to tell looking over your shoulder it just seemed to float back down ...after that i shut it down ...when i double check everything i,ll run it again and get a pic.. looks like lots of issues with tracking in low (even medium) winds ...

but worth building it just to see the furl ...

....thinking a bit more about this its strange it went all the way to the upper stop during the highest gust ..at this stage the springs are starting to relax and dont have a big influence niall |

||||

| philb Regular Member Joined: 05/07/2008 Location: United StatesPosts: 96 |

Niall, You have reached the most difficult and fun part of the whole project.  I would have been thinking... when will the wind blow?... I would have been thinking... when will the wind blow?...

I have enjoyed reading your post and I look forward to the updates. I have thought about building a downwind turbine for years. I suppose I did have one once.  Here's the story on otherpower. http://www.fieldlines.com/story/2006/12/3/18522/2088 Here's the story on otherpower. http://www.fieldlines.com/story/2006/12/3/18522/2088

I remember the 'downwind' version of my turbine not having the same fast response to wind shifts. I attributed that to balance and not enough tail (blade) surface area to turn it. I thought about flipping the blades around and letting it fly. At the time, it was winter and I needed the lights and heat for my greenhouse, so I repaired it and put it back in the air. Proven Energy has a vane you can probably adapt to yours if the need arises. The thought of having a true downwind unit still crops up. I've got to try this design. Thanks for the post! philb |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

Philb...i really like that machine .....surviving the breakage and soldering on downwind was quite a feat of loyalty ..

looks like both machines suffer the same problem ..poor yaw response bigger blades dont seem to help...mine can be caught out sideways (feathered) into medium winds and refuse to move...lots to think about furling migh,nt be such an issue then...yawing is a huge one ..i,ll track down a proven ....

finally got a pic of the furl....its been doing this a good bit all evening ...the frisbee effect is the best way to describe it..

niall |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

i let the mill run for a while and its suffering a few big drawbacks ... mainly very poor low wind tracking and when it furls high a strange annoying tendency to rotate around the mast on its way down , often leaving it feathered into the wind or putting a twist in the cable..its kind of cure one problem create another , a vane would help but i think the offset just isnt big enough to do it justice .....

also the blades i think should be coned a bit to help the yaw ..but i cant really try this either without a whole new prop...coning seems to be a big thing with downwind machines it does though seem a good canditate for some type of active yaw experiment

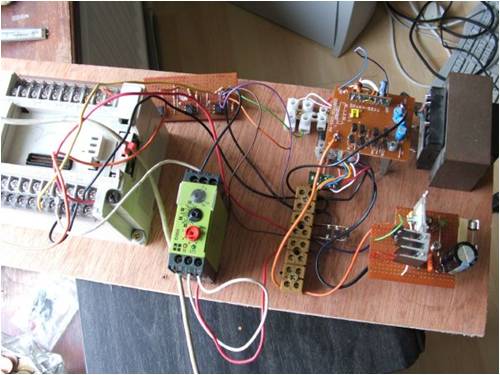

the small up wind vane sends right/left signals back to a plc via a toy car transmitter..even with the dodgy wiring this is working well ,this way i can leave the plc next to the computer

the plc can send signals back the same way to a yaw motor (no ideas yet for the motor ..  .)..it shouldnt need to be active very often , maybe once every hour and hopefully make a correction (with some feedback from the vane) and then the yaw should lock...if i can rig a motor it could be a lot of fun (not quite so practical though) .)..it shouldnt need to be active very often , maybe once every hour and hopefully make a correction (with some feedback from the vane) and then the yaw should lock...if i can rig a motor it could be a lot of fun (not quite so practical though)

ps.......Gordon i did try improving the yaw bearing action (alignment) with a temporary roller bearing at the base of the yaw pipe which made it a lot more responsive to changes in wind direction ..

....the unexpected side effect was the strange rotation during the furl... niall |

||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

Hi Guys OK I've just read this topic 3 times while I sit here testing an electromagnetic brake on a Chinese turbine. I recently configured it to run downwind to control stability, I didn't bother with furling initially but it has been on my mind for a while. So here are a few random thoughts! Nearly all the mechanical systems I have seen seem to fly in the face of the KISS principle though some are vastly better than others. From what I have read (here & elsewhere) there are some probs with tracking, reduced power & vibration from the blades passing through the wind shadow of the mast. I am going to persist with the electromagnetic brake for a while but mechanical furling may still be where I end up so keep at it guys. A thought on dampening - have a look at a degassed strut from a car Hatchback or for a smaller option a motorcycle steering damper (not the friction type) I think a lot of the probs are from turbulence created by the turbine body & the furling mechanism, making the blades run in "dirty air" With no furling mechanism my turbine had a very clean aerodynamic profile (See pic below). The electromagnetic brake worked fine & it seemed to turn the turbine offwind when it activated - possibly from torque reaction but I can't quantify that theory yet. Problem is that if the brake ever fails in high winds I want to be in another state when the turbine explodes. I have also been investigating the idea of converting a centrifugal clutch from a small motorcycle or scooter into a mechanical brake but as I am living in a Motorhome I lack a lot of workshop facilities, does anyone else have expertise or knowledge in this area? I am beginning to think that downwind is the best option for turbines if the furling prob can be overcome with a simple cost effective mechanism. If you consider the forces acting on a turbine, upwind is inherently unstable & downwind tends to be more stable. Things I took into consideration were the center of gravity, center of pressure & the distance of them from the pivot point. On a downwind machine you get a pendulum effect according to the distance from the pivot point. the longer the the distance the slower the turbine reacts to the wind direction, with an upwind turbine these effects are reversed. Larger diameter blades may get the tips into cleaner air & the increased gyroscopic effect may also help stability. There are so many variables involved in this I think it is going to take a lot of work from many ppl to quantify the results & designs so keep at it guys. If anyone has a wind tunnel for rent & a Mathematics Professor as an Uncle it may make it a bit easier. OK, wind gusts here are hitting 70 kph so I'm going back to Chinese electronics & Valium. Look forward to seeing where this topic finally ends up David A low Tech solution to a complex problem - as long as the brake doesn't fail Murphy was an Optimist |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Just an idea, but would it be considered cheating to mount a tall dorsal fin on this thing to battle against the angular momentum of the prop, which may be causing it to "precess' about the vertical axis the way a gyroscope does when it spins on a permanent mount? I know I have to aim my sail plane's electric motor slightly to the starboard side to counteract the angular momentum of the spinning prop. I'm not sure if this happens with a "driven" prop, like in a windmill, but it may be what's happening. Might be worth thinking about. Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Rodin Newbie Joined: 10/09/2009 Location: AustraliaPosts: 10 |

Thanks MacGyver, you've just proved to me that Beer, Valium & Physics don't mix. I looked at the option of a dorsal fin/vane & intend to try it sometime but I totally missed the idea of gyroscopic precessing. I was looking at using it to stop the turbine starting in reverse in a sudden gust of wind. Now I have a new variable to calculate into the equation Thanks Mate!!!!! Regards David Murphy was an Optimist |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

the precess or sponsored walk around the mast (at least in mine) seems to be a gyro effect ..its always in the one direction adding a fin MacGyver would help but i think it would need to be big enough so as not to be counter productive ... my mast is only 3inch pipe but it does leave a small wake , enough to make a small helicopter noise effect, if the fin didnt sit properly into the wind it might leave a very big wake behind it , right up to the blades ...cant be fully sure about this but thats why i,m reluctant to squeeze one in (the small tower offset limits things now) Rodin the offwind action during braking effect on your mill has similaraties here too...in my case it happens when the mill is close to a stall condition , it gets a bit peaved , and seems to go offwind a little (but its unpredicable).. warts and all clip... http://www.youtube.com/watch?v=hWRyLk4H8-s conta rotating props needed then. ...

because i cant..  .. play with coning the prop , for now i,ll cheat and stick with the active yaw cause .. play with coning the prop , for now i,ll cheat and stick with the active yaw cause

ps..thinking a lot more about this it seems a bit like flying a kids diamond shaped kite ,both are downwind machines ..

any good kite like this will have a few degrees backsweep on its sides leaving it more stable ..now take the same kite and make it a pure flat diamond shape , chances are it,ll never leave the ground , if it does it,ll have very little idea which direction the wind is coming from and constantly hunt for it ....... niall |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Niall: Nice video. I like the way you got a shot of the prop tilting out of the wind flow during a gust. Very nice! Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| wind friend Newbie Joined: 01/05/2007 Location: AustraliaPosts: 39 |

hey niall remember the f117 stealthy thingy. it too had a triangular shape. skunk works solved the instability with computers, mmmm. if i am not watching my wind turbine or thinking about wind turbines and i have a moment? i can be found flying kites. your diamond kite with only one line usually has a tail to help keep it stable and a flat diamond kite with two lines will always need some input from the flyer to keep it one spot. hans |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

hi Hans.. we used to fly a lot of them when we were young here (no xbox,s then...  )..anyone who owned a stunt one was treated like a kind of god....all that reckless flying close to the ground impressed the girls.... )..anyone who owned a stunt one was treated like a kind of god....all that reckless flying close to the ground impressed the girls....

now i,m thinking about the sweep (dihedral?) thing , i think i,ll make a new prop , its bugging me too much niall |

||||

| wind friend Newbie Joined: 01/05/2007 Location: AustraliaPosts: 39 |

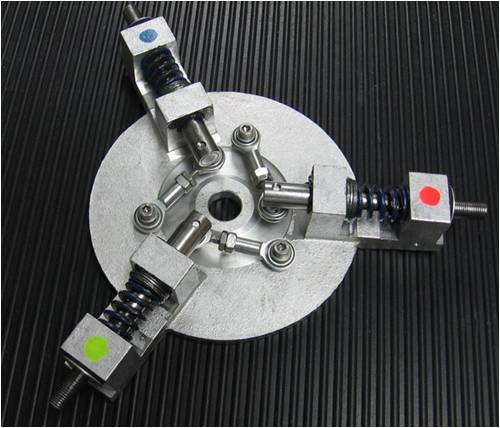

(down wind) furling? found this pic on the web and wondered if it could be simplified. the hardest part would be getting the spring tensions correct. it looks simple enough, but would it be worth all the trouble of extra bearings, could it be made to work in the weather?

hans |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Hans, I've seen that picture a few weeks ago too; think it was from a commercial site, someone who also converted car alternators to windgenerators? At the time the site was still heavily under construction; can't for the life of me recall where I saw this, RonB gave me the link. At the time we were having a discussion about it, as I don't see how all three blades would vary pitch at the same time. The way I understood the mechanism, it was possible for each blade to have a different pitch, leading to imbalance and (most likely) self-destruction. The price of the contraption in your picture was pretty reasonable too, I remember. And should be doable to modify it in such a way that, as with the Jacobs mechanism, all blades will always be set at the same pitch. So, it needs to be 'complified', not simplified, to make it work reliably. At least as I understand it so far. I may be overlooking something though. Sorry, not really related to this thread, but the first thing that popped into my mind when I saw the picture. Maybe Ron can chime in too if he sees this. Peter. |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

Peter...this thread was off thread .... before it even knew it was a thread ....  niall |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

I agree with you Dinges, it needs the synchronizing spider designed into it. ............oztules Village idiot...or... just another hack out of his depth |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Regarding turbulence downwind of the mast how about putting an airfoil shape on the mast? It would have to swing with the wind, somehow. Probably daft, it would certainly look odd, but I wonder what the effect would be of wrapping the mast in something 'fluffy', like a sheep skin (full fleece of course).  Remember that a convertible top on a car makes less noise if it is made of fabric that is a bit fluffy. Remember that a convertible top on a car makes less noise if it is made of fabric that is a bit fluffy. |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

[quote=Niall]the precess or sponsored walk around the mast (at least in mine) seems to be a gyro effect [/quote] Niall, I only now noticed your remark of the gyro effect causing the yawing and I fully agree. As soon as the turbine furls upward there will be a powerful gyroscopic precession effect that tends to turn the turbine around its yawing axis, where it has a degree of freedom and thus can move/rotate. The same effect occurs with the furling of normal, upwind turbines, except there it tends to bend the mast (not exactly correct, it's not bending but a moment) either forward or backward. As there is no freedom of movement here (apart from some flexibility in the construction), nothing really happens. In the downwind situation with upward furling, however, the gyroscopic precession effect will cause the turbine to rotate out of the wind as it is furling upward - the lesser wind it'll see in that case will cause it to unfurl again, and then movement due to gyroscopic precession in the opposite direction takes place. In effect, it'll be hunting and have trouble settling down in a stable, furled situation. Possible solutions? Damping could help, as you have basically a mass-spring-damper system that's underdamped and thus tends to oscillate. But it'd complicate the contraption, and the main advantage of downwind/upward furling would be it's simplicity, as opposed to elliptical furling. Funny, it's a problem that I'd never thought of in downwind turbines until I saw your remark, even though it should've been pretty obvious, in hindsight. Niall, I think you've hit the hammer on the nail with your analysis of gyroscopic precession. Peter. |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

thanks for the explaination Peter (and Macgyver)... the vertical furling (tempting as it is) ...seems to ask more questions than it answers , the hub bearing will probabely be taking a lot more stress due to the extra force moments (it,s a heavy alt with a minimal bearing) this , i,m really not to keen about at all (i,ll keep things in one piece for now and not let it get to stressed out ...  .) .)

i think i,ll keep the downwind layout...(might get to use that fleece yet kiwijohn....  .) .)

just rethink the furling problem ..having to over-mod a downwind machine does defeat the purpose a bit its all good though ...the bits that arnt quite working out are the interesting ones.....

ps ...after a trawl on the net trying to learn something i did find one pdf.... Catastrophic Failure due to Gyroscopic Effect of Small Scale Tilt up Horizontal Axis Wind Turbines Mahinsasa Narayana;....... cant understand it ....but just love the title.... niall |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Niall, Recently I fixed a dishwasher for a bloke from up the north of this island. It turns out he has has a Soma windmill running for the last 6 years without incident. Interestingly, it is a head-lift furling type, and has only 2 blades.... 9' diameter. This is an Australian unit.... the Irish bought out our Westwind machines I think...... Not sure when I will get time to get up there and take him up on the offer to look at it, but I am more interested to do so now. They have solved these procession problems, and now I am curious to look at it. It is an upwind type with a straight tail (solves procession and tower noise)

Maybe a better way to go??

............oztules Edit..... somehow I just know you will build one of these soon

Village idiot...or... just another hack out of his depth |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

No doubt I will get jumped on for mentioning this but blades with some flexibility in the root, be it hinges or a spring, can handle a lot of the various upsetting forces without transfering all the disturbance to the mast. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |