|

|

Forum Index : Windmills : Decogging F&P

| Author | Message | ||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Thanks Guys Nice to know we are in this together. Like Bruce, I have been around long enough for most of the criticism to pass without sticking. Just occasionally, it is a good feeling to get up someone who is being a bit too precious - I got banned from a Range Rover forum for daring to criticise the administration's flawed logic! For windvanes and other types of alternative energy - let's keep at it. Have you seen my boating forum at www.handymariner.com.au/ ?? |

||||

| vasi Guru Joined: 23/03/2007 Location: RomaniaPosts: 1697 |

I like SMF forums, easy to setup and manage ... great options. You have "tutorials" about building this kind of boats? Hobbit name: Togo Toadfoot of Frogmorton Elvish name: Mablung Miriel Beyound Arduino Lang |

||||

Bushman Regular Member Joined: 24/04/2007 Location: AustraliaPosts: 41 |

Hi Vasi Sure - the job of that site is to help find resources for boat design, repair & mainetance. Let's not hijack this windmill forum - join up on the Handymariner forum and let me know what you need Cheers Alan |

||||

| CanTinker2 Newbie Joined: 21/01/2008 Location: CanadaPosts: 14 |

I was in the middle of decogging my F&P and remembered this thread. About half way through, I started sanding down the edges of the poles on an angle thinking that it might accomplish the same thing as twisting the poles. Anyway the results are very good, the cogging is only a small fraction of when I started. I only wish I could compare a stator decogged on an angle (on all the poles) to one done normally.

Sorry about the picture quality, I should have used something better than a cel phone camera. John |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Should be the way to go then John as that looks really easy and maybe more gentle than an angle grinder. BTW, nice Falcon ute, hope you didnt get sparks on the paint!  |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Thats very clever John. I did try grinding poles at an angle once but the powerfile I was using didn't work very well so I gave up, didn't think of using a rotary sander thingy. Using the rotary sander you have would make it a lot easier. Let us know how you think it all went once the mill is finished. I should put a web page together on decogging the poles. How big was the sanding drum, and how many did you need to finish the job. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| CanTinker2 Newbie Joined: 21/01/2008 Location: CanadaPosts: 14 |

It took some experimenting, I started with a narrow sander (like the one in the pictures) I bought just for the job, but I settled with the old drum sander with a 2 inch or 5 cm diameter drum. The metal must be very soft because it was an used 80 grit paper roll that I used worked well for the entire stator. Like I said I did not think of turning it on an angle until I was half done so I have half straight and half on an angle. It is difficult to hold the sander on the angle to get it started though, the sander wants to jump over the pole in the direction of rotation, so you have to hold it tight and watch where its grinding. I just finished wiring the stator with your single 5 pole and triple 3 pole conefiguration you came up with. I separated the 5 pole in between the 3-3 pole sections of the stator to give the stator a more balanced load. Of course its not perfectly balanced, two 2 pole 3 phase sections for the 5 pole Y are separated in between 3 pole 3 phase sections leaving one 3 phase section roughly 120 degrees around the stator from the other sections of the 5 pole Y connection. It required more soldering, and I don't know if it would make any difference. KiwiJohn noticed my poor welding skills, I'm sure I'll get better. I just took up welding for this project, I no longer have my professional welder freind to rely on. Anyway its worth a laugh. John |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Sorry John, I dont think that is poor welding at all, in fact I think it is just a little better than mine!  |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Hi,very new here and to this type of web site.I took on the idea of twisting the poles.To make them more uniform I made a tool which locates fairly accuratly over the end of each pole and in 2 mins all poles are twisted approx 10 deg.Then a light file or cut on the lathe to remove the high spots that occur at the 2 outermost corners of poles and no more heavy cogging. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Jarbar. Welcome to the site. Sounds like a good idea. I think someone else here tried the same thing once, but not sure how well it went for him. Do you have a photo? Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| herbnz Senior Member Joined: 18/02/2007 Location: New ZealandPosts: 258 |

Hi I have also twisted pole pieces Mine has the windings removed, I perfer to re wind than reconnect. I was waiting to report progress until performance is fully tested. Some perliminary results tho cogging on standard setup = 0.3 NM cogging on rounded poles = .012 MN cogging on twisted poles + .015 Mn I believe the loss of generated emf at a given rpm will however be the most signifigant advantage of the twisted poles initial tests show little to no loss wheras grinded poles at least 10 % to Compare I need to arrange three identical windings.  |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

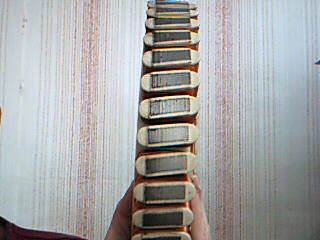

Hello,thanks for you interest.All it needs is a light cut on the lathe to finnish a uniform looking modification.The shape of the tool allows maximum clearance, purchase and control of twisting action.I hope this posting works as well?????????. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Great idea,,I'm a bit dumb ,,could you explain in more detail how that tool works and how do I make one,,dimensions,,what are the screws for ,bla bla,,much appreciate that Bruce Bushboy |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Hello Glenn,I am in the process of configuring a VAWT to use 2 F&P units believing that if I configure them correctly electrically that I can utilise the the high tourque and low revs to better advantage.I found twisting with windings to be no problem,just a slight creaking sound of windings relaxing into new position.I have considered purchasing ecoinnovation's manual but don't know if it's going to cover this option.Mechanically endowed but electrically on slow charge. Anthony "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Hi Bruce,the tool is made from a piece of black bar 20x10x400 long.The stator poles plastic moulding is 40mm across from the top of the radius to radius and 14 mm wide.So mark two centres 40mm minus radius 7x2 14mm =26 along centreline and drill two 14mm holes to about 4mm deep.Then mill out the area between the holes leaving the edge intact.In other words we now have a slot 14 wide and 4 deep and 26 long to the centres.If you have a slot drill just mill the slot.This will give maximum purchase to the plastic moulding of pole.You then need to open the edge on opposite ends to allow maximum rotation of tool before it impinges on the adjacent poles.After twisting the poles on first rotation a second twist would also be possible but probably unnecessary.The screws are non existant they are where my 14mm drill point bottomed out.I didnt have a 14mm slot drill so I cleaned out slot with 12 mm end mill. Anthony. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Great Anthony,, that explains the jig real good.. I'll mill out a slot in some stock and get back to you ,,if this can be done then it opens up a whole new area of experimentation---just what we need<hahaha.. Thanks Bruce Bushboy |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Hello Bruce or Glenn,somewhere on this site was a photo of an F&P used for a Milling MC table cross feed.I should have saved it.And of course I now can't find it.It had alink to another DIY site also???????. "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Here's the link, it was posted by Vasi. Clever idea, a F&P as a cheap and powerfull stepper motor. http://www.thebackshed.com/windmill/forum1/forum_posts.asp?T ID=895&PN=1 Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Jarbar Senior Member Joined: 03/02/2008 Location: AustraliaPosts: 225 |

Glenn thanks for your promt reply.But it may now I have looked at it be best suited for what it was intended.I need to wire an F&P to drive the deck of an inversion MC around with me laying on it horizontal to the ground.I have a chronically injured lower back and wish to apply some traction to it using centrifical force.After seeing that application for mills it occured to me an F&P would be ideal.Just as a motor.I already use this form of traction to some posotive effect.ie a bit like spinning a cosmonaught in a gravity generating device.But getting my wife to stand there pushing my feet as they whiz around has past its use by date.Now as crazy as it sounds it definitely has some merit in the relief it affords.If I can attach and run F&P from a 12 volt battery through some type of potentiometer to control the speed of rotation,I can then modulate the speed before my head flys off.Or burst that annurism.My condition causes me to be chronically fatigued most days,but I must find a soloution.I am sure many others could benefit from this idea.But then again? Anthony "Creativity is detirmined by the way you hold your tounge".My Father "Your generation will have to correct the problems made by mine".My Grandfather. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5167 |

Hi Anthony. I myself wouldn't go there. Its easy to use the F&P as a alternator, but bloody difficult to use it as a motor. It can be made to run, sort of, but not very well. We tried to use one to drive a solar car many years ago and after several months gave up, see http://www.thebackshed.com/mackaysolarcar/. I think it would be a lot easer and cheaper to use a motor from Oatley Electronics. You can pick up and 500 watt motor and matching speed controller for $160! They also sell chains and stuff to suit. http://www.oatleyelectronics.com Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |