|

|

Forum Index : Windmills : Progess photos

| Author | Message | ||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Gordon At present my caps are 50uf 100 volt bi polar audio if I wanted to improve on the low rpm out put what caps and or changes would you suggest? Phill I do agree with you the aluminum tubing has very little if any structural strength. I did have to turn down the steel cores to fit them in to the aluminum. After building what I consider a strong, ridge spindle assembly and then going with aluminum would seem to be a contradiction I know. I have decided to keep things as they are and ride it out. Yeah it's a bit of a gamble, a gamble that I hope will pan out. I do believe my mill will peak at or around 500 to 550 watts which is no where near the performance level that you experience hence less pressure no the mill. You once quoted to me (the moment of truth) well that moment hasn't yet arrived as I have not seen any winds over 25 mph. I do believe that my mill started to furl at or around 15 mph. No cringing please, if you cringe that means I have to cringe. Mac No doubt about it I suck at math so if I did any ciphering it would indeed be very little if you know what I mean. Closest neighbor is approximately 200 feet to the west with a stand of trees about half way between us. The strongest wind I get here are from the W NW with the mill facing those direction I have no homes for a very long distance. My mill is up 47 feet about the same as the tree tops. After me you guys will be the first to know if disaster strikes. Will keep you posted. Thanks for all your input. Jim |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Ok I've got some new numbers on out put. Thinks are looken up over here. Single stator F&P 36 finger 60dc-7s-2p Delta, Neo magnets, caps voltage doubler. Moderate winds. 602 peak watts/9.05 peak amps so far.

Jim |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Jim, The audio caps will eventually short over time. Not high enough power rating. The can is quite small. I used these on my first 24V unit. I had made a voltage doubler with 2x33uF @ 100VAC Audio caps for each cap position. I had one cap go short. Replaced complete unit with 100uF @ 200VDC caps instead. These are about 3 times bigger, physically. All working well now. The WattsUp meter works well as a companion to logging as well. I have one, as I mentioned a while back. The peak hold function is really useful. Wish there was a max volts hold instead of a min. These are intended of course for the electric powered model enthusiast. Gordon. become more energy aware |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Gordon Thanks for all your help. Honestly I didn't think the mill would preform as well as it has. I am starting to have some serious fun over here now, still waiting for the big blow to see how she holds up. Moderate winds now I think she can pump out 700 watts will find out in time?? I am really impressed how the cap system you've developed kicks out the wattage, it was a HUGE improvement over here. I kinda figured the caps were smaller and used for smaller or start up systems. Think I will post pone the larger caps for now and will go with larger ones later but when that time comes I will again take your advice and go with the 100uf. I still have to up grade my 12 vols system to 48. I am using some car batteries to test my mill. With the mill proving to be something that really works I can now move forward and incorporate it into my home system. Yeah gotta love Watts Up with out it I would basically have no idea what the heck was going on.

Jim |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Made a few changes to increase performance. 1.Reduced the alternator offset. 2.Changed the tail offset as well. She is now facing directly in to the wind during average wind speeds which should increase over all amp hours. 697 watts peak, 11.35 amps peak, with caps/voltage doubler @ 25.4 mph winds. Looks as if these changes help to keep the mill from turning out of the wind to soon. I do believe the mill it's self has reached or has gotten very close to it's max out put. There is more room for improvement with different cap arrangements. She's still there and flying. With the winter winds, ice and snow on there way we will see how well it hold up?

Jim |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Jim, readers should be aware, that the important number in the photos above is only the Ap, and the Wp in the bottom left position of the LCD. The WattsUp meters have a peak record function, and the numbers scroll at that display position. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Jim, It may be wise to check to see if it still furls ok.... otherwise you may have set yourself up for runaway and overspeed. Try and make sure the new furling changes still protect you from armature reactance problems. ...........oztules Village idiot...or... just another hack out of his depth |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

OZ The tail has moved about half furled so far and has furled several times. Haven't had higher winds as of yet. I have been watching it carefully. Seems to be Ok for now but the jury is still out. I wasn't at home when she reached Ap, Wp. My anemometer recorded 25.4 mph. Haven't had any problems stopping it with dynamic braking I would think that the neo's helped. Thanks for your concern. Your comments and warnings are always heeded. Jim |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

25.4MPH.... mmmm I've seen windspeeds recorded by my logger of 49.7 m/s this is 112MPH.... anemometer is 3m up mounted on the chimney of the house..... which is sheltered by trees... The most incredible day I have ever seen was this day http://en.wikipedia.org/wiki/Black_Saturday_bushfires I saw a peak windspeed (in your terms!) of 90mph and most alarmingly the temperature was 125F degrees. The fires at that point were 200 miles away and the neighbour was dumb enough to say we weren't at risk. I could have dropped a cigarette and wiped out another 10,000 acres! outside you could watch the garden die like in fast foreward, the cows were drinking the troughs dry faster than they could re-fill and that wind was so great that I had to catch my 4 year old so she wouldnt get blown away. Mother nature will teach us all a lesson some days!! unfortunately lots of people died that day and If I lost my windmill under those circumstances, it would be the least of my worries. all sound good so far though... Luck favours the well prepared |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

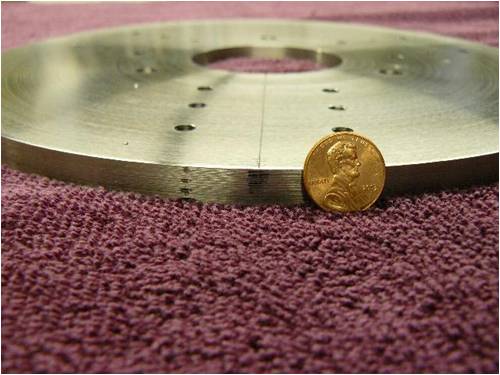

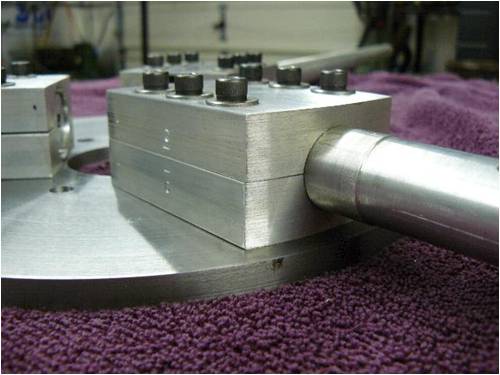

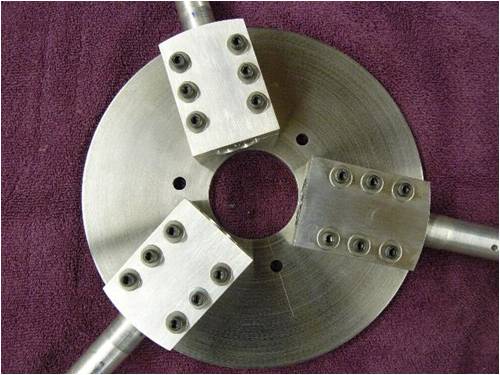

My mill has performed better then I could have imagined over all I am very pleased, however I have had some problems keeping it properly balanced. After a winter of several heavy blows, it has development a slight wobble or an imbalanced situation and of course, it has been driving crazy. I said to my self (this cannot go on!) Therefore, I set out to design and built a better blade mounting system. I was using 1” steel cores in alum tubing. This is of course is a very lightweight arrangement; I believe this is what contributed or help cause the instability. The mill stayed together even with the Alum tubes instead of steel or stainless.

I remained with steel for the hub plate. Starting out with ½ thick plate but decided it was to heavy and cut it down to 3/8. The original plate was 3/16 thick.

I used 6061-T6 extruded alum rectangle stock to machine three mounting blocks to mount the alum rods to the steel hub plate. Using six ¼ 28 socket head cap screws per mounting block to secure both the blocks and rods to the hub plate gave me plenty of pressure to keep things nice and tight. Maintaining a gap of approximately 20 thousands of an inch between the upper and lower extrude-ions applies a spring pressure (if you will) on the rods to eliminate the cap screws loosening from vibration.

I decided to go to 1” 6061-T651 solid alum rod instead of tubing for blade mounts. The rods extend 3’ in to my existing 4’ long blades. Using external e clips on the rods ends helps keep the blades at the same length from the hub and adds some security to keep the blades from flying off in cause the mounting bolts work them self’s loose.

I turned out three-center points to increase accuracy in measuring tip-to-tip distance. Tip to tip is 1/16 of an inch. Blade run out measures 1/8 on an inch.

This time balancing came relatively easy because all components where kept within a close tolerance. I bolted one small weight to the end of one blade and that did the job. I believe the imbalance came form the cast iron drum

I’ve had the new system up and flying for three days with moderate winds and all is well no wobble or vibration. Happy days are here again. As always, any comments are most welcome. Jim |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Wow! That's some fine workmanship. I love seeing well executed home builts. Looks like I have to go back to the start and read through this whole thread. Perry |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Jimbo Top Job mate some real thought has gone into this, now all you have to do is work out how to put some twist into the blades to increase their efficiency a bit.How did you fit the neo's did you use the original rotor or a reinforced one, this interests me as I am making a twin stator machine and would like to get the best output I can to make the effort worthwhile, Karl is running a dual machine but only getting similar power to your single. How about a picture of the whole machine now with the new hub. All the best Bob Foolin Around |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Great build BUT the highway department may want their stop sign back! Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

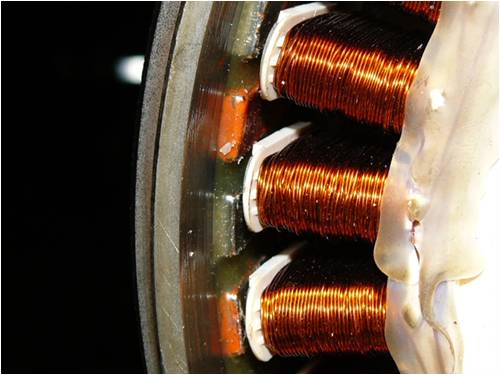

VK4 Photos of my mill are in this topic, (earlier posting)here are a few pics for you to view. Neo's where mounted with fiberglass resin. The drum (rotor)is cast iron. The spindle and drum are from a 1700lb trailer assembly.

The neo magnets are what give my single stator the ability to produce the same or similar out put as the dual stator with ceramic magnets.

DomWild Stop sign long since gone. I opted for a down sized No Passing Zone sign!! Jim |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yes Jim , I agree with that output. Mine gave around double the ceramics. Working on an LG hub soon . They appear to be a much sturdier (steel) and larger 25% hub and stator . Also the shaft is larger (30mm) and bearings are much larger. Nice work ,Jim post results soon Bruce Bushboy |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi Jimbo , As usual you have done excellent work on your new blade hub , it makes a big difference when everything is in line and balance . Always a pleasure to see your work  PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Jimbo Thanks for the photos I did see your earlier photos but didn't twig on the rotor construction really a top job I am very interested in doing a neo conversion for my twin rotor one as I haven't started on the engineering yet so it is a clean slate, yours looks like a 100 series stator so we are on the same track a little info in the neos would be appreciated supplier price etc. Also some info on the little digital meter you have would be appreciated. Keep up the fine work. All the best Bob Foolin Around |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi Bob, I think I put Jim onto the WattsUp meter. I got mine years ago, online from the manufacturer in the US. Around $50- . Probably more, better spec units available now. These are used by modellers testing electric motors in cars, planes etc. Gordon. become more energy aware |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Gordon I will be doing an ebay and google search tonight. Thanks Mate All the best Bob Foolin Around |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Bruce During lathe testing the neo's easily out performed the ceramics. I seen your LG posting. The LG's look very nice. The larger diameter hub/rotor should lead to some impressive results. Looking forward to seeing your progress. Thanks. Phill Haven't heard much from you lately. (your up to something) Getting the nod of approval from you is definitely appreciated. I think I am nearing a point where I can honestly say that my mill is good for the long haul. She's now running very smooth. I do believe with the blades being heavier that a change in the furling point (tail weight)will have to be done. Thanks VK4 Gordon is correct he gave me the go ahead with the Watts Up meter. I must admit I did burn out a couple of meters because of over voltage. Do not let the voltage go over 60v or it will die a very fast death, but over all it's nice to have especially when it reads out wattage. My stator is an 60dc-7s-2p-star/delta. Can't say I am very good at rewires so I purchased from EcoInnovation, yes it was on the expensive side but it did come with a warranty and has performed well. There is very little or no clogging with this 60dc unit even with the neo's. On Gordons advice I run it in Delta and use caps/doubler. The caps most guys are using with ceramic magnets did not work well for me. A 150uf will stall the mill 50uf to 100uf is what I use, the neo's change things a bit. Forum member imsmooth is the guy you want to contact about the neo's. I purchased them through him. He did the design work. I like when things work. Bruce is working on a LG hub setup you may be able to start with a larger and heavier LG stator. I would probably go in this direction. Keep in mind that wind mills take a beating so stay on the heavy side if you can just my thoughts. I think the members that are using the PVC/ALUM blades would agree they are the ticket and affordable. I have often played with the idea of a dual stator/ single rotor, how ever with a cast iron rotor this would get pretty heavy. Some light truck spindles may work well and a Alum rotor would be a hott setup. I can't help thinking that my future may have a AX/FX type of alternator. I designed my new hub with the ability to accept steel cores (rods)so that it would be able to handle the torque requirements of a 2k mill. Looking forward to your progress. Jim |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |